At the end of the new year, many people travel thousands of miles home to reunite with their relatives

.

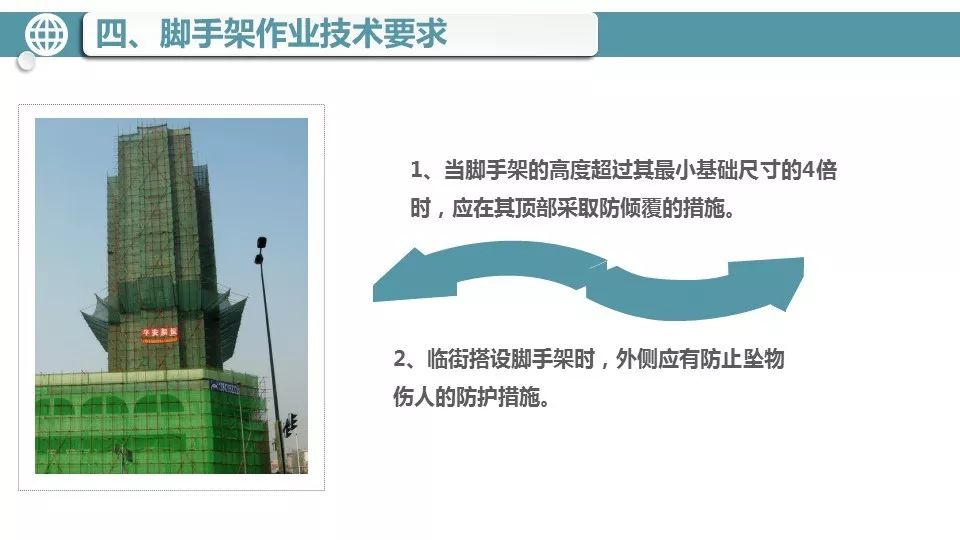

However, some people are separated from their relatives by accident At about 9:00 on January 9, 2020, at the construction site of the logistics complex building and guard room reconstruction project of Suzhou municipal Party School of Suzhou high tech Zone, Suzhou City, Jiangsu Province, a steel pipe fell from the fourth floor (about 11 meters high) during the scaffold dismantling process, and hit a site guard (male, 47 years old, Tongcheng, Anhui Province) on the head

.

The project was completed The medical department immediately sent him to Suzhou Mingji hospital for rescue

.

Due to ineffective rescue, the worker died at about 11 o’clock on the same day

.

At about 16:00 on January 14, 2020, at the construction site of Cuihu science and Technology Park on the east side of Thrushcross Shandong Road, Haidian District, Beijing, a worker of a Construction Engineering Co., Ltd

.

in Beijing accidentally fell from a height during the process of dismantling scaffolding, and then died after being rescued by a hospital

.

How to prevent falling accidents reported by Beijing Emergency Management Bureau? From top to bottom, the scaffold should be erected first and then dismantled, and then erected and dismantled first

.

Preparation for scaffold dismantling 1

.

According to the structure of scaffold and site conditions, the dismantling scheme should be prepared and approved by relevant departments

.

2

.

Before the scaffold is removed, the safety scope shall be defined and the warning line shall be set

.

The project leader shall call the relevant personnel and operators to conduct a comprehensive inspection on the scaffold, focusing on whether the fastener connection and fixation, support system, etc

.

meet the safety requirements, and the operators shall be familiar with the scaffold erection on site

.

3

.

Confirm that the building and floor materials have been transferred, and the scaffold is not needed before demolition

.

4

.

Before dismantling, carefully check and timely remove the floor ash, concrete blocks and other materials or debris left on each layer of scaffold, and do not leave any materials and debris with potential safety hazards

.

5

.

When removing the unloading steel wire rope, rigid wall connecting rod and cantilever rod of scaffold, without the consent of the construction personnel and quality safety personnel of the project department, any operator on site shall not remove them at will, so as not to affect the quality and safety of scaffold

.

6

.

When the scaffold is removed, the on-site operators must take protective measures and fasten the safety belt

.

The scaffold can only be removed after being checked and approved by the construction personnel of the project department, and the safety personnel shall track and supervise the scaffold on site

.

7

.

When the scaffold is demolished, according to the situation of the demolition site, the warning belt set outside the site must be guarded by a specially assigned person, and it is forbidden for people irrelevant to the demolition to enter

.

8

.

Organize the demolition personnel to do a good job in the safety technical disclosure, and have the signature of the recipient of the disclosure, and clear the relevant safety technical requirements that should be paid attention to in the work for the operators

.

And prepare the safety belt, rope, spreader, tools and transport personnel

.

9

.

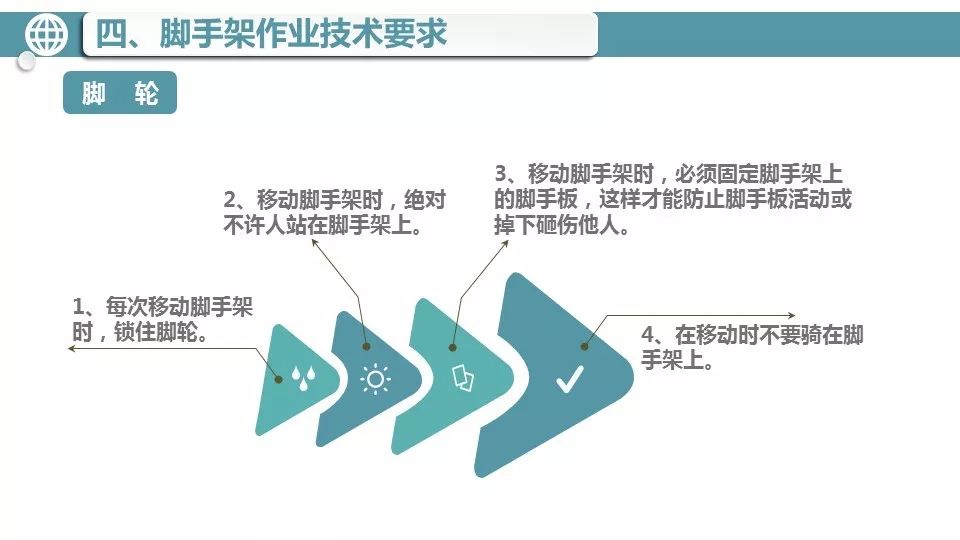

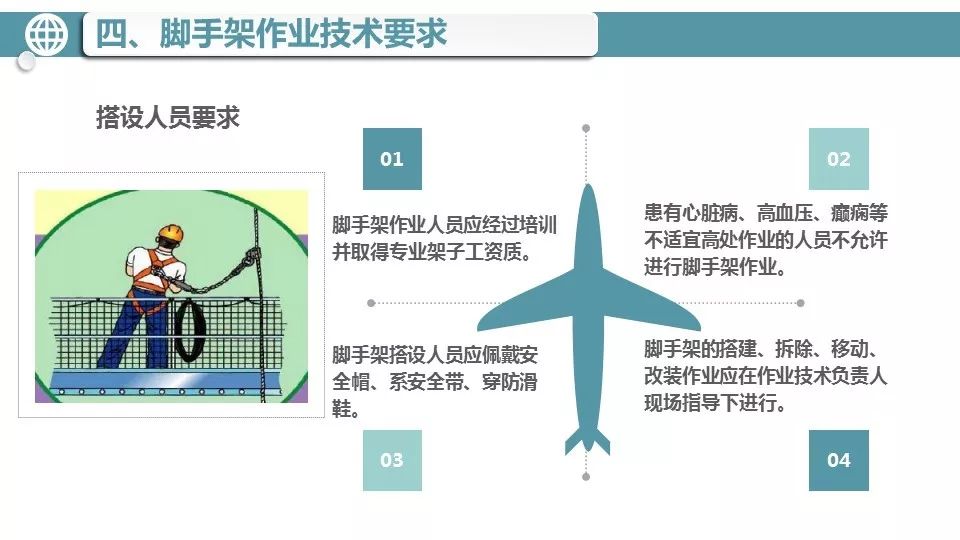

The dismantling personnel must be full-time scaffolders and hold the operation certificate of special type of work before they can participate in the operation

.

10

.

Specific safety disclosure shall be conducted by the safety department of the project department

.

The construction steps and key points of the second outer frame demolition shall be in accordance with the principle of “from top to bottom, first erection and then dismantling, and then erection and dismantling first and gradually”

.

It is strictly forbidden to work up and down at the same time, and it is not allowed to use step type or adopt section and elevation demolition

.

All wall connecting rods shall be removed layer by layer along with the scaffold

.

It is strictly forbidden to remove the whole layer or several layers of wall connecting rods before removing the scaffold

.

Temporary wall connecting rods shall be set for reinforcement when removing the wall connecting rods

.

1

.

Construction technology of scaffold removal

.

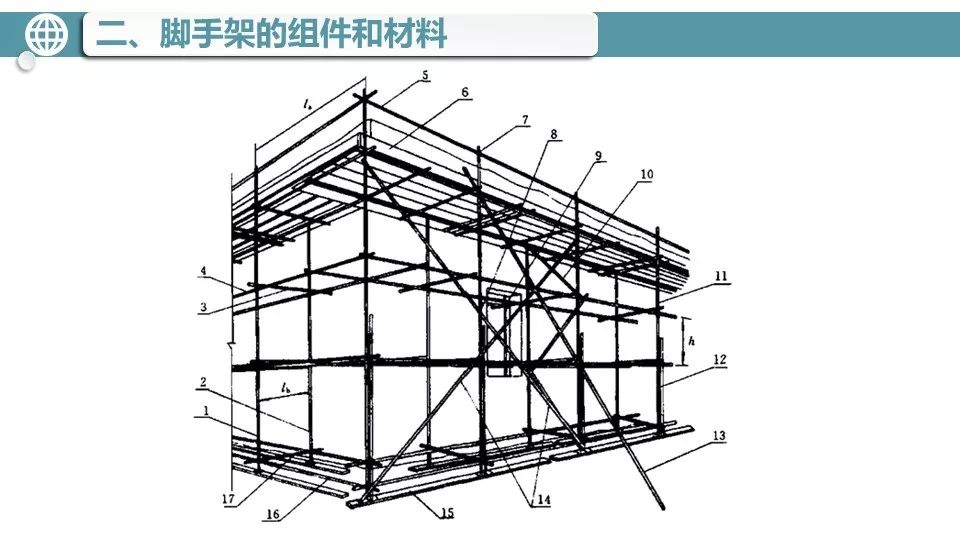

The general order of scaffold removal is: safety dense mesh → toe board → bamboo fence → cross bracing (only on the removal layer) → diagonal bracing (only on the removal layer) → throwing bracing (only on the removal layer) → small cross bar → large cross bar → vertical bar → wall connecting bar

.

The cantilevered channel steel and unloading steel wire rope of each section of cantilevered scaffold shall not be removed until all the scaffolds are removed

.

2

.

Precautions for rod removal: before operation, workers must check personal protective equipment and put it into use only after it is qualified

.

Check whether the tools used are firm to prevent injury caused by falling

.

Safety helmet and safety belt must be worn when working at height or in the air

.

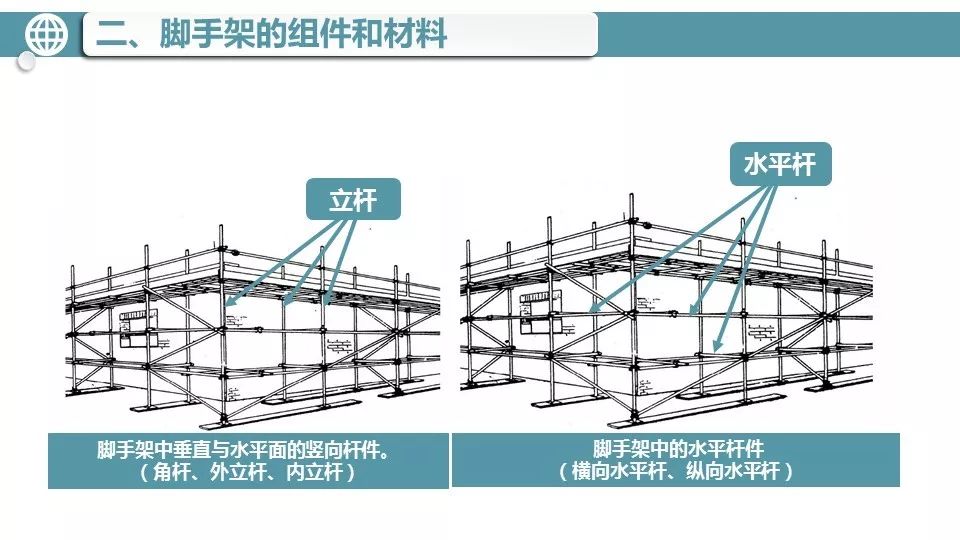

① Upright pole – hold the upright pole first, then loosen the butt fastener, pull out the upright pole immediately and stably, lay it flat on the pipe for one step, and then take out the fastener, which cannot be left on the next upright pole

.

It is absolutely not allowed that the vertical pole is in an independent and free state after the fastener is released, and it is not allowed to be removed in time; the removal personnel can not work alone, but should cooperate with two or more people to ensure the safety of removal

.

② Big cross bar, cross brace, diagonal brace – remove the middle butt fastener first, hold the middle, and then release the end buckle; cross brace and diagonal brace can only be removed on the removal layer, not all at one time

.

When removing the cross brace, the safety belt must be fastened, and more than two people cooperate to remove

.

③ Throwing support – the throwing support can be removed only after it is reinforced with temporary support

.

④ All wall connecting rods and unloading wire ropes shall be removed layer by layer along with the scaffold

.

It is strictly forbidden to remove the wall connecting rods in whole or several layers before removing the scaffold

.

If the height difference is greater than 2 steps, the temporary wall connecting rod shall be added for reinforcement

.

⑤ When the scaffold is removed to the height of about 6.0m of the last long steel pipe in the lower part, the temporary throwing support or tie should be set up at the appropriate position for reinforcement, and then the wall connecting rod should be removed

.

⑥ The demolished steel pipe shall be transferred from top to bottom and placed on the scaffold board not demolished in the lower layer, but the quantity, height and form of stacking shall be in accordance with the safety standards

.

Tower crane or construction ladder shall be used to transport the steel pipe to the ground, and it is not allowed to throw the steel pipe at high altitude, so as to ensure safety

.

Attention shall be paid to the protection of interior and exterior wall decoration surface and curtain wall, and finished product protection

.

⑦ The loosened fasteners shall be removed in time and placed indoors

.

They shall not be thrown at high altitude

.

They shall be packed and transported to the ground with tower crane or construction ladder

.

⑧ When the safety flat baffle is removed, the diagonal brace can be removed only after temporary reinforcement at appropriate position

.

⑨ In the process of dismantling the scaffold, it is not allowed to change people halfway

.

If it is necessary to change people, the dismantling situation should be explained clearly before leaving

.

Before leaving the site, the operators must check the scaffolds removed by themselves or the adjacent personnel, and deal with the loose scaffolds before leaving

.

⑩ Fences or warning signs must be set up around the scaffold

.

In the process of dismantling the scaffold, a special person shall be assigned to give unified command, echo up and down, and coordinate the action

.

When another related knot is untied, the other party shall be informed first to prevent falling

.

⑪ Materials and tools shall be transported by tower crane, and the removed materials shall not be thrown

.

The materials or components to be lifted must be bound firmly before lifting

.

It is not allowed to hurt others or damage buildings and public property during lifting

.

The materials transported to the ground shall be transported at the designated place along with dismantling, stacked in categories, removed on the same day and cleaned on the same day, and the removed fasteners shall be recycled in a centralized way

.

3

.

Safety measures for outer frame removal: 1

.

The personnel engaged in outer frame removal must have special work license

.

When dismantling the scaffold, the safety technical disclosure must be made to the operators

.

The team leader must clearly hand over the relevant safety technical requirements of scaffold removal to the operators

.

② When operating, operators must correctly wear safety helmet, fasten safety belt, wear anti-skid shoes, and wear tool bags

.

Tools should be put into bags after use, and should not be put on shelves, so as to avoid falling down and hurting people

.

③ It is strictly forbidden to dismantle the scaffold after drinking

.

The scaffold dismantling personnel must be in good health, and the personnel with history of hypertension and acrophobia are not allowed to be put on the scaffold

.

④ The removal of the outer frame should be carried out in the daytime, and the area maintenance should be done well

.

Warning signs should be hung at the obvious place of the passage and supervised by special personnel

.

In the whole process of demolition operation, the project safety officer should do a good job of on-site inspection, set up a warning area at the main channel, and arrange the guard to inspect, so as to ensure the smooth progress of demolition operation

.

⑤ When removing the outer frame, first remove all the bamboo fence boards and safety nets, and then remove them from top to bottom

.

When removing the outer frame, first remove the cross bar, and then remove the vertical bar

.

It is not allowed to work up and down at the same time

.

The wall connecting parts must be removed simultaneously with the scaffold.

.