Ad00 catalog 01, earth excavation safety production standard 02, foundation pit construction channel 03, foundation pit drainage engineering safety production standardization 04, foundation pit surrounding stacking load control 05, foundation pit support safety production standardization 06, foundation pit and support structure monitoring 01, earth excavation safety production standard 1

.

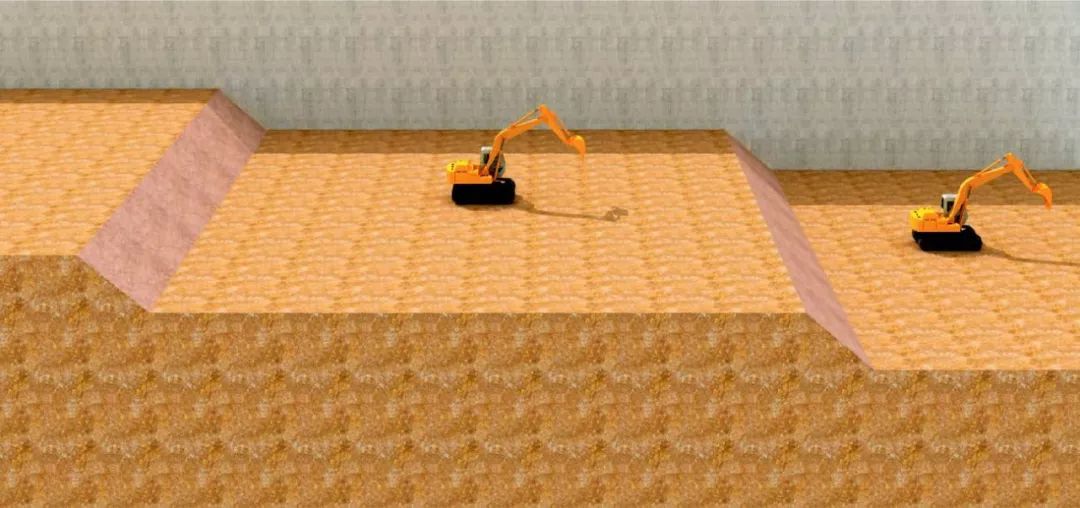

Special construction scheme must be prepared for earth excavation to clarify the specific excavation method, excavation sequence and slope The excavation operation must be carried out in layers according to the sequence, and over excavation or excavation is strictly prohibited

.

2

.

Before the earth excavation, the pipelines within the excavation scope shall be investigated, which shall meet the design requirements, and the quality of the enclosure structure shall be inspected

.

The earth excavation can be carried out only after the inspection is qualified

.

3

.

In the process of earthwork excavation and basement structure construction, after the completion of each process, the construction quality of the process shall be inspected, and the problems found in the inspection shall be rectified, and the next construction process can be started only after the rectification is qualified

.

4

.

In the process of excavation, the monitoring shall be strengthened

.

If any abnormality is found, the excavation shall be stopped immediately

.

According to the monitoring data of foundation pit support system and surrounding environment, the construction sequence and method of foundation pit shall be adjusted

.

Risk construction is strictly prohibited

.

5

.

When there is underground water within the scope of earthwork excavation depth, effective drainage measures shall be taken to ensure that the underground water is 50cm below the excavation surface of each layer of earthwork, and excavation with water is strictly prohibited

.

6

.

Drainage ditch should be set around the foundation pit, and protective railings must be installed

.

The height of protective railings should not be less than 1.2m, and upper and lower passages should be set in the foundation pit

.

7

.

The plane and vertical layout of the construction site shall be consistent with the support design requirements, and major changes in the layout shall be approved by the design

.

The drainage ditch and enclosure shall be set around the foundation pit according to the sequence of layered excavation

.

2

.

The construction channel of Foundation Pit 1

.

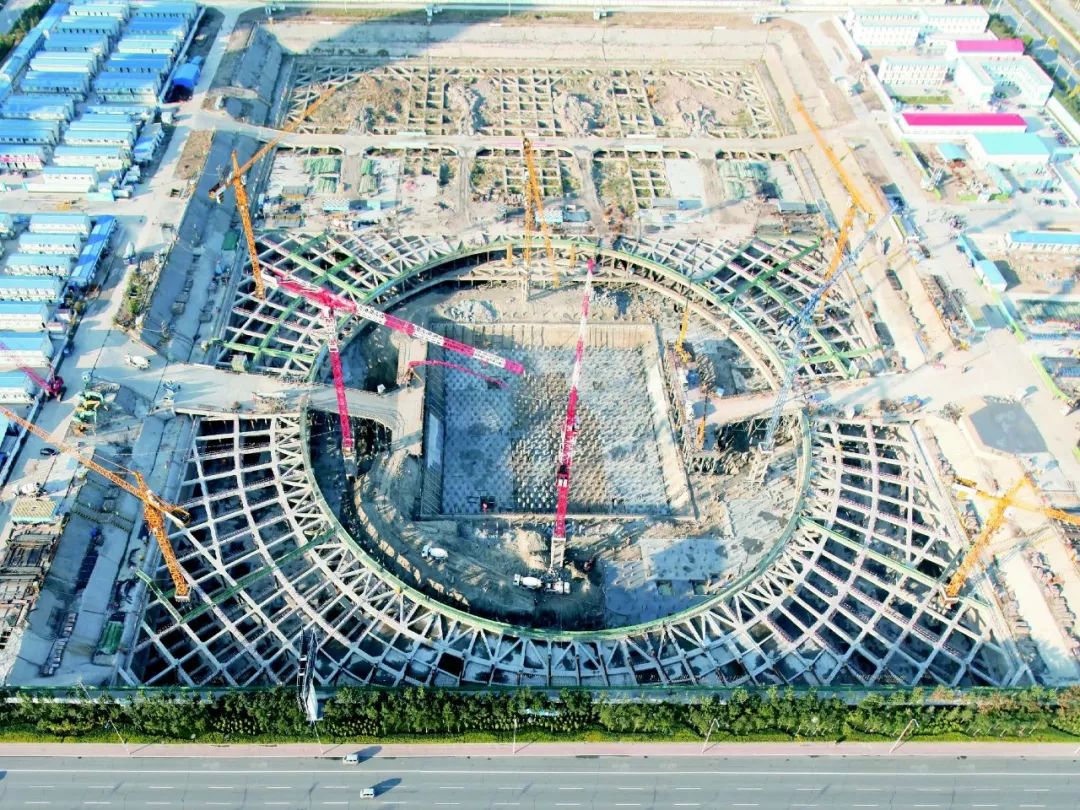

The channel of foundation pit adopts the diversion of people and vehicles

.

2

.

The side of the vehicle passage should be graded according to the actual situation on site to prevent the collapse of the lane

.

The warning signs such as colored flags and protection shall be set at the side of the lane

.

3

.

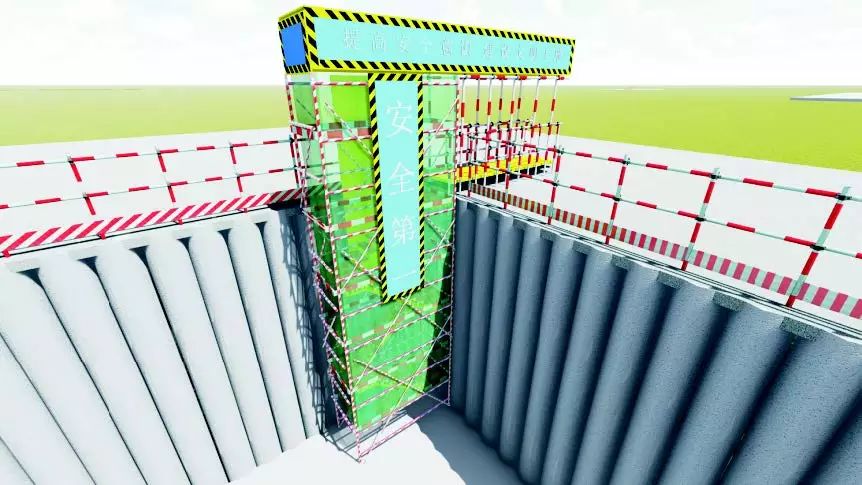

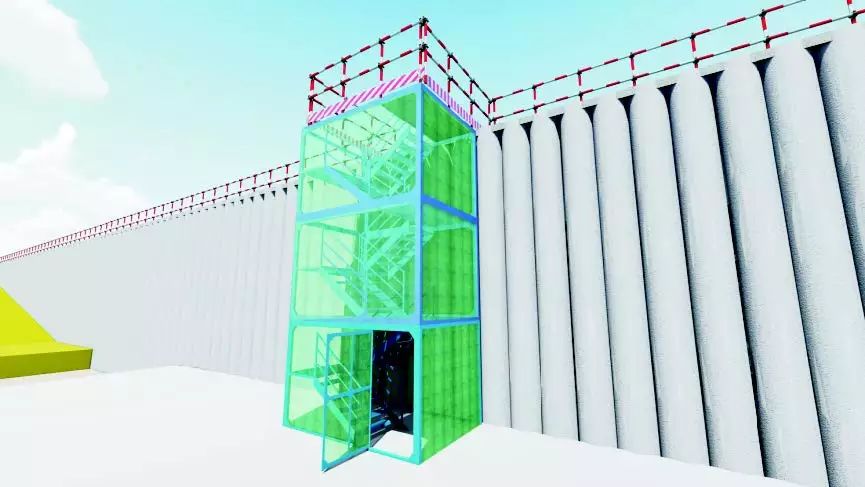

Pedestrian passageway can be divided into all steel standard section customized type and steel pipe erection type

.

Foundation pit construction channel schematic diagram foundation pit stereotyped steel channel schematic diagram foundation pit pedestrian ladder schematic diagram foundation pit pedestrian ramp schematic diagram 03 foundation pit dewatering and drainage engineering safety production standardization 1

.

The upper, lower and surrounding of the foundation pit must be equipped with drainage system, the flow direction and slope rate should be obvious and appropriate, no ponding

.

2

.

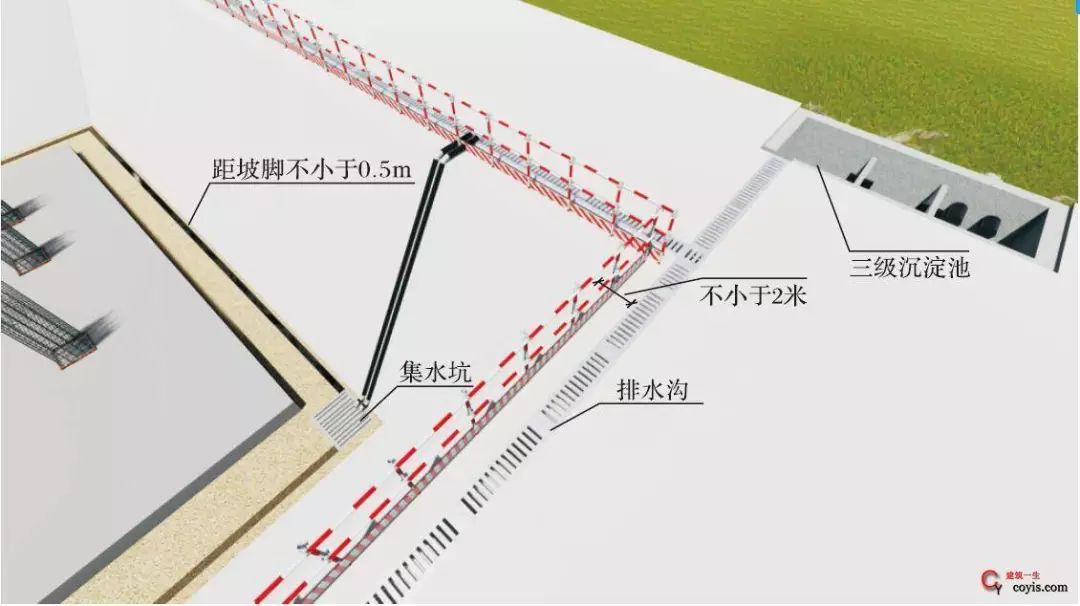

The distance between the upper drainage ditch of the foundation pit and the edge of the foundation pit should be more than 2m, and the bottom and side walls of the drainage ditch must be treated with anti-seepage treatment

.

3

.

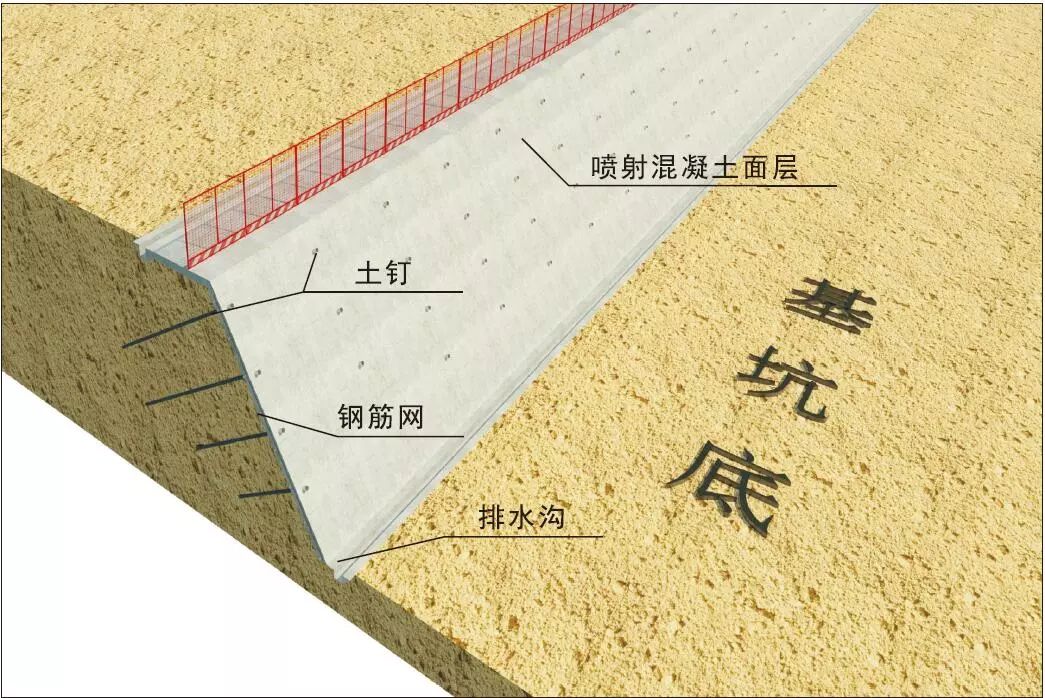

Drainage ditch and sump should be set around the bottom of the foundation pit, which should be placed outside the underground structure, and the distance from the slope toe should not be less than 0.5m

.

4

.

The depth and width of the drainage ditch should be determined according to the displacement of the foundation pit, and the size and number of the sump should be determined according to the underground water volume and the ponding area

.

5

.

Drainage equipment shall be set in the sump at the bottom of the slope to drain the water to the drainage ditch at the top of the slope, and the water shall be discharged after sedimentation in the three-stage sedimentation tank

.

6

.

The dewatering well should be arranged in the outer ring of the foundation pit; when the area of the foundation pit is large and there is a deep excavation area in some parts, it can also be arranged in the foundation pit

.

Foundation pit drainage engineering 04 foundation pit surrounding surcharge control 1

.

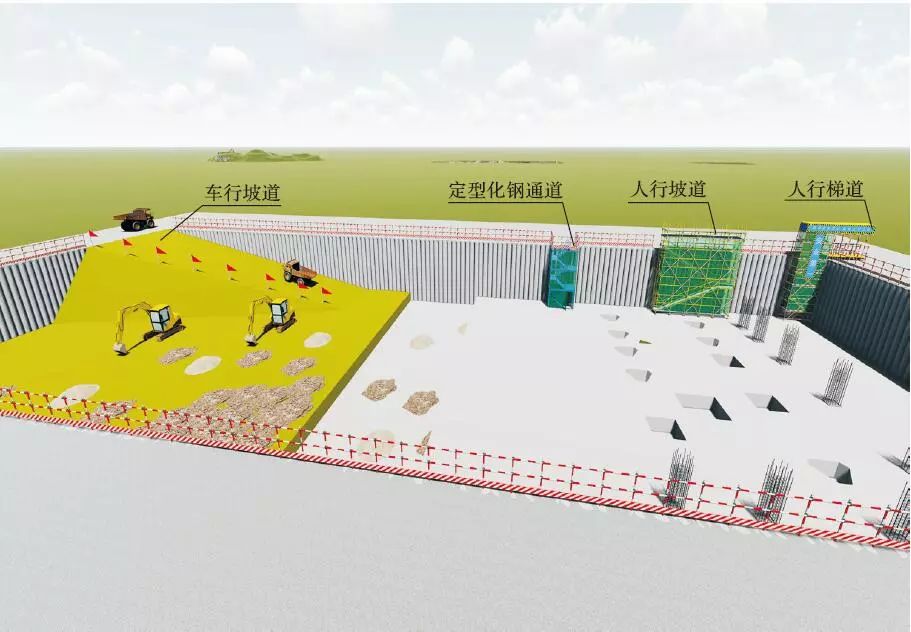

The service load around the foundation pit shall not exceed the design value, and the surrounding surcharge shall meet the requirements of technical code for construction safety of Deep Foundation Pit Engineering (jgj311-2013)

.

2

.

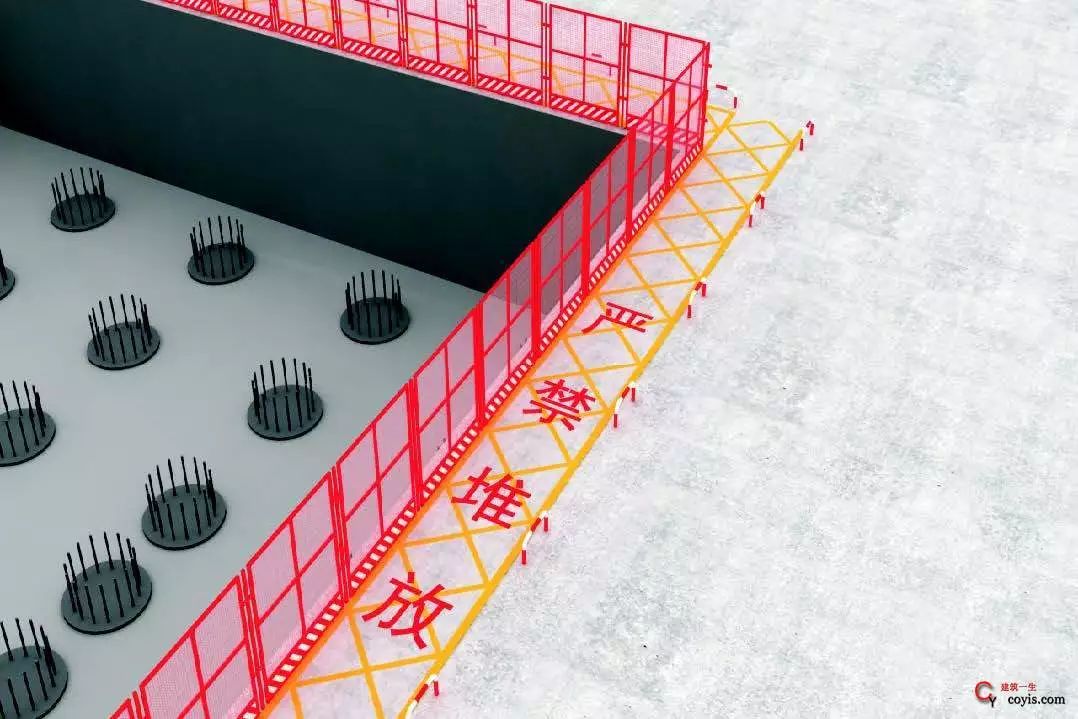

No surcharge is allowed within 1.2m around the foundation pit, and the surcharge is limited within 3M

.

3

.

Heavy vehicles are not allowed to pass by the pit

.

When the stacking load and vehicle operation have been considered in the support design, it must meet the design requirements and overload is strictly prohibited

.

4

.

The construction of temporary housing or warehouse within one time of the depth of the foundation pit should be approved by the foundation pit support design unit, and approved by the technical director of the enterprise and the project director

.

5

.

Obvious safety warning signs or warning signs should be set at the dangerous parts, edge and free positions of the foundation pit

.

It is advocated to draw a warning line within 1.2m of the foundation pit, and write the warning words of “no stacking” within the warning line

.

Foundation pit side load limit and warning diagram 05 foundation pit support safety production standardization catalogue 1

.

Construction scheme 2

.

Natural slope, soil nailing wall foundation pit support 3

.

Pile anchor foundation pit support 4

.

Reinforced concrete foundation pit support 5

.

Steel support foundation pit support 6

.

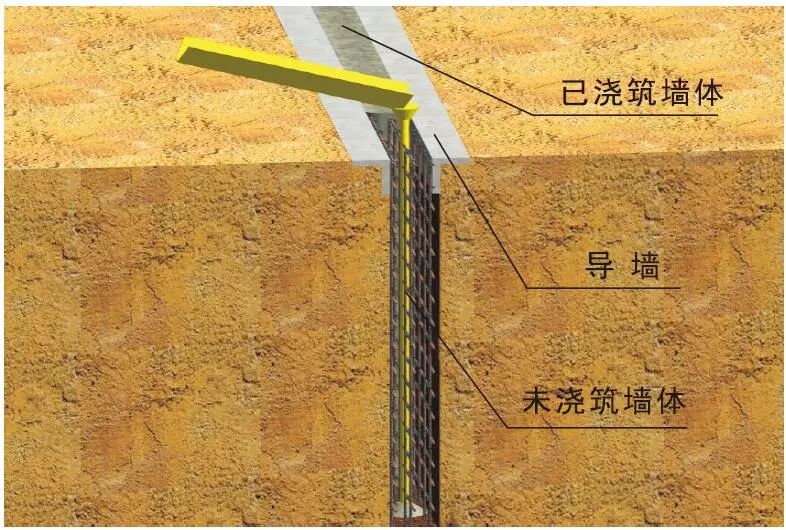

Underground continuous wall foundation pit support 1

.

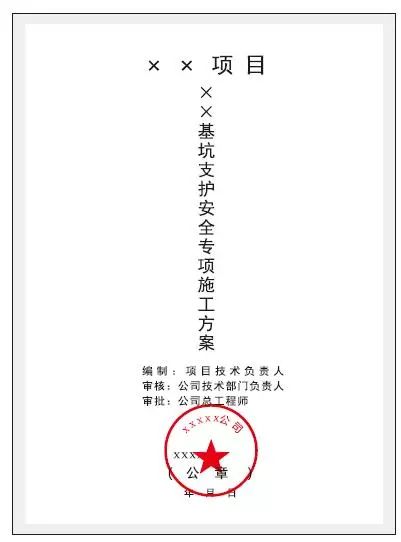

Construction scheme 1

.

Excavation depth is less than 3m or less than 3m, However, special construction scheme should be prepared for earthwork excavation, support and dewatering works of foundation pit (trench) with complex geological conditions, surrounding environment and underground pipelines, or affecting the safety of adjacent buildings and structures

.

2

.

The scheme shall be reviewed and signed by the technical director of the construction unit and the chief supervision engineer

.

If it exceeds a certain scale, it should be demonstrated by experts

.

3

.

The foundation pits that need to be demonstrated by experts include: Earthwork excavation, support and dewatering works of foundation pits (grooves) with excavation depth more than 5m (including 5m)

.

4

.

Foundation pit support and excavation, protection measures for buildings (structures) and underground pipelines within the main influence area, surrounding ground drainage measures, groundwater control measures, surrounding load, deformation control of support structure, monitoring data, etc

.

shall meet the requirements of relevant specifications and special construction scheme

.

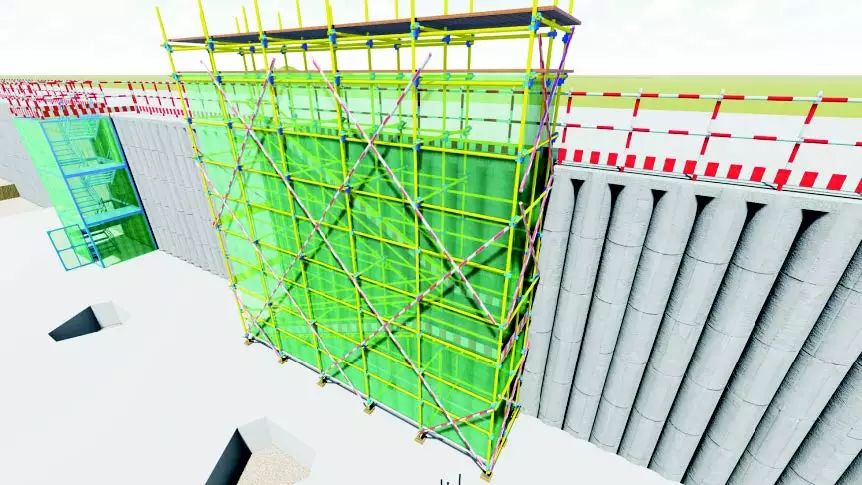

Special construction scheme of foundation pit support schematic diagram of foundation pit support II

.

Natural slope and soil nailing wall foundation pit support 1

.

The natural slope angle shall be determined according to the site soil conditions, and the scheme shall be made clear

.

2

.

Slope in strict accordance with the foundation pit construction scheme, and set drainage ditch, collecting well and other drainage measures

.

3

.

During earthwork excavation, the safety of surrounding buildings, underground pipelines and roads should be ensured, and deformation monitoring should be done well

.

4

.

When the actual soil layer excavated is obviously inconsistent with the survey data, or abnormal conditions occur, the excavation shall be stopped

.

5

.

The slope of soil nailing wall and prestressed uranium rod composite soil nailing wall should not be greater than 1:0.2

.

6

.

When the support above the excavation face does not meet the design requirements, it is strictly prohibited to excavate downward

.

7

.

In the construction process, temporary overhead measures must be taken for wires, and power distribution shall be carried out according to three-level power distribution and two-level protection

.

8

.

Check and accept the mechanical equipment when entering the site to prevent the old 18 equipment from entering the site

.

Soil nailing wall supporting schematic diagram 3

.

Pile anchor foundation pit supporting 1

.

Special construction scheme shall be prepared for pile description supporting, and supporting piles and uranium rods shall be set in strict accordance with the scheme

.

2

.

Effective dewatering measures should be taken in the process of support, and deformation monitoring should be done well

.

3

.

Concrete crown beam shall be set at the top of supporting pile

.

The width and height of crown beam should not be less than 0.6 times of pile diameter

.

4

.

The construction sequence of concrete cast-in-place piles should be divided into piles, and the adjacent piles should be constructed after the final setting of concrete

.

5

.

When the unknown obstacles are encountered in the process of drilling, the nature of the obstacles should be found out and the construction can be continued under the condition of ensuring safety

.

6

.

The anchoring section should not be set in loose fill layer such as silt

.

Cement slurry or cement mortar shall be used for grouting, and the strength of grouting consolidation body shall meet the requirements of the scheme

.

7

.

The anchor bolt machine must be placed stably, and the live stones on the slope surface shall be removed before construction

.

8

.

When pouring cement slurry, pay attention to the pressure of the pump to prevent accidents caused by pipeline blockage

.

Pile anchor support schematic diagram 4

.

Reinforced concrete support foundation pit support 1

.

Reinforced concrete support must be constructed in strict accordance with the scheme, adhere to the “slotting support, support before excavation, layered excavation, over excavation” principle

.

2

.

Reliable dewatering measures must be taken during foundation pit excavation to ensure construction safety

.

3

.

Strictly follow the foundation pit monitoring scheme, do a good job in deformation monitoring, timely suspend the construction in case of any abnormality, and take measures to ensure safety before continuing

.

4

.

When the reinforced concrete support is horizontal support, the waist beam connected with the retaining member should be set

.

When it is located at the top of the retaining member, it can be connected with the crown beam

.

5

.

The formwork shall be removed after the concrete support strength meets the scheme requirements to ensure that the strength meets the stress requirements

.

6

.

When concrete support is used as pedestrian passage, protective measures must be taken.

.