Click on the top to pay attention to “home of engineering construction” and get 618 current specifications

.

Source: what is “standard” on the Internet? That is to say, in order to get the best order in a certain range, it is a kind of normative document to formulate common and reusable rules for actual or potential problems

.

1

.

The key requirements of bridge construction technology standardization are as follows: first, do a good job in template access, and do not allow unqualified templates to be used in production, so as to ensure the appearance quality of concrete; The second is to control the prefabrication process of beam and slab to ensure the concrete strength, the thickness of steel protection layer, and the thickness and flatness of bridge deck pavement; The third is to do a good job of “first article analysis system”

.

After the construction of each bridge, the first finished product or semi-finished product such as pile foundation, pier column, beam, etc

.

is completed, the chief inspector’s office shall organize the construction unit to analyze the quality status, process details, etc

.

and form a formal report before batch construction

.

2

.

Standardization of bridge substructure construction technology (1) standardization requirements of common bridge foundation construction 1

.

Bridge Bored Pile Foundation ① Fabrication of reinforcement cage Common problems: the joint of the main reinforcement of the reinforcement cage is wrong, the diameter is 25 mm, and the reinforcement should be mechanically connected instead of double-sided welding; And the cushion block of reinforcement cover is not used

.

Standardized construction requirements: a

.

When the diameter of reinforcement is greater than or equal to 25 mm, mechanical connection should be adopted, and protective sheath should be added after the wire head passes the inspection

.

b

.

The round cake type cushion block shall be used for the protective layer of reinforcement cage, and the longitudinal interval shall not be more than 2m

.

Each cushion block shall be set symmetrically along the circumference and shall not be less than 4

.

② Common problems of steel cage processing site: standardized construction requirements: The reinforcement cage shall be fabricated on the hardened site where the cement pedestal is set

.

After fabrication, the reinforcement framework must be laid flat and the mould shall be standardized

.

③ Common problems of mud pit: standardized construction requirements: After hole cleaning, the mud index should be the average value of sampling from the top, middle and bottom of the pile; The surrounding area should be protected

.

④ Common problems of reinforcement cage placement: ⑤ Reinforcement cage placement: The placement shall be aligned with the hole position, stable, slow and straight to avoid colliding with the hole wall, and the pier cage and twisting cage are strictly prohibited

.

After placing, the reinforcement cage shall be prevented from sinking or floating

.

2

.

There are some problems in bored pile Standardized construction requirements: Sufficient lighting, ventilation and exhaust facilities shall be provided in the hole of bored pile, and escape ladder shall be provided at the same time

.

The hole shall be covered with fence and warning sign, and the hole shall be 30cm above the ground

.

3

.

Expanding the base FAQ: standard construction requirements: The base is 0.5-1m wider than the plane size of the foundation

.

The bearing capacity and geological conditions of the base meet the design requirements, so the geotechnical test should be carried out( 2) Bridge pier construction standardization requirements 1

.

Pier construction ① The formwork installation of pier and capping beam shall meet the allowable deviation, and the lifting of bucket shall be directed by a special person

.

② After the formwork is removed, the column shall be immediately wrapped with plastic film, and the pier top drip irrigation and other methods shall be adopted for maintenance

.

2

.

Common problems in abutment construction: standardized construction requirements: ① The abutment formwork generally adopts large steel formwork or large bamboo plywood

.

② Formwork reinforcement and support: the formwork and support shall be removed after support, and the latter support shall be removed first

.

3

.

Standardization of Bridge Superstructure Construction Technology (I) standardization construction requirements of Prefabrication Yard 1

.

Common problems of Prefabrication Yard hardening and drainage setting: standardization site requirements: the site shall be hardened with concrete above C15

.

The hardening thickness shall not be less than 10cm and 15cm when used as carriageway

.

Standardized construction requirements: For the bridge with longitudinal slope, triangular wedges should be set at the supports at both ends of the pedestal to ensure the levelness of the supports

.

The spacing between precast pedestal and beam storage pedestal shall be greater than twice the width of formwork

.

3

.

Common problems of standardized steel formwork: standardized construction requirements: The core formwork of precast box girder and hollow slab girder shall be set steel formwork, which shall meet the relevant requirements of “formwork access system”, and shall be reported to the chief inspector’s office for inspection and acceptance

.

4

.

Common problems of diaphragm bottom formwork: (2) standardized construction requirements of beam prefabrication: In order to ensure that the bottom formwork of the diaphragm can still play a supporting role after the removal of the side formwork, the diaphragm must use an independent steel plate bottom formwork, which can be removed after the tensioning construction( 3) Steel processing standardization requirements common problems: standardized construction requirements: 1, rainproof shed setting The roof rainproof facilities should be set up in the steel processing yard, and the steel structure should be used, and the lightning and wind protection facilities should be set up

.

The outdoor temporary steel stacking place should be covered by mobile roof

.

2

.

Reasonable zoning The steel bar processing yard should be set up scientifically and reasonably according to the raw material stacking area, steel bar blanking area, processing and manufacturing area, finished product stacking area, semi-finished product stacking area, waste area, etc., with clear functions and clear identification

.

3

.

Intellectualization Popularize intelligent steel bar numerical control processing machinery, reduce labor intensity, improve production quality and production efficiency( 4) Precast beam construction process requirements 1

.

Common problems of precast beam reinforcement positioning: Standardized construction requirements: ① Special jig for reinforcement The reinforcement should be assembled on the special jig, and then hoisted as a whole

.

The position of the structural reinforcement should be accurately marked on the jig, so as to effectively ensure the accuracy of the installation position of the reinforcement and avoid the lack of reinforcement

.

② Reinforcement positioning a

.

Positioning of T-beam reinforcement: the reinforcement binding of rib plate shall adopt the method of fetal membrane, which shall be hoisted on the pedestal as a whole after installation

.

b

.

Positioning of top and side reinforcement: the top and side shall be fixed with reinforcement, and the positioning tie bar shall be pulled outside the formwork with a tightening device

.

③ Common problems of diaphragm reinforcement positioning: standardized construction requirements: The triangle support positioning frame is adopted

.

After using the steel bar positioning frame, the installation is accurate and the framework is firm and neat

.

④ Analysis of common reinforcement binding problems: standardized construction requirements: According to the specification, the end of stirrup should be made into hook, and the hook angle can be 135 °。 The length of straight section of hook should not be less than 5 times of stirrup diameter for general structure, and 10 times of stirrup diameter for seismic structure

.

2

.

Bellows ① Common problems of positioning reinforcement: standardized construction requirements: a

.

The circular reinforcement is made to pass through the corrugated pipe and welded on the framework

.

The position of corrugated pipe and anchor plate shall be fixed accurately according to the design

.

b

.

Points for attention in positioning reinforcement construction: reinforcement interfering with corrugated pipe shall not be cut off, and reasonable measures shall be taken to avoid it

.

② Common problems of corrugated steel bar protection: standardized construction requirements: a

.

The connection of bellows should use the same type of bellows as the joint pipe, and seal the joint of bellows with sealing tape to ensure no slurry leakage

.

b

.

The length of the prestressed bellows with negative bending moment at the end is 5-10cm, and it is wrapped for protection

.

c

.

Before pouring, the circular bellows should be lined with a plastic hose 1cm smaller than the inner diameter of the bellows to protect the bellows

.

③ Slurry stopping measures Effective plugging measures should be taken to ensure that the template does not leak, and foam filler should be used to fill the joints and stop the slurry

.

3

.

Common problems of protective layer cushion block: standardized construction requirements: The plum shaped high-strength mortar cushion block is used to ensure that the cushion block can bear enough pressure without breaking

.

At the same time, the double wire binding method is used

.

4

.

Common problems of attached plate vibrator: standardized construction requirements: The edges and corners of the formwork and the places where the vibrator can’t vibrate shall be supplemented with drill rod vibration

.

The top plate of precast beam shall be vibrated with plate vibrator, and the web plate shall be vibrated with attached plate vibrator

.

The vibration time shall be controlled properly

.

5

.

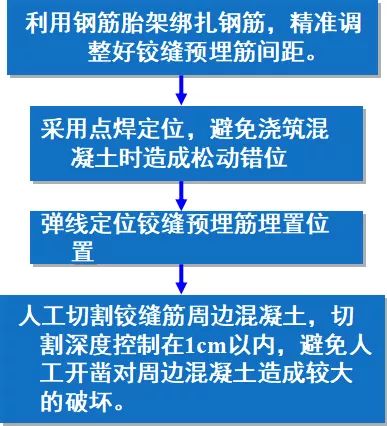

Common problems of hollow slab hinge joint reinforcement: standardized construction requirements: 6

.

Beam chiseling Common problems: standardized construction requirements: The beam top shall be roughened before initial setting, and the wet joint part of the beam shall be mechanically roughened immediately after formwork removal

.

7

.

Prestressed intelligent tensioning and grouting ① The concrete strength before prestressed intelligent tensioning shall not be less than the design value.

.