1

.

Foundation engineering problems: pile tip steel plate thickness can not meet the requirements of the drawing Cause: the materials have not been accepted by three parties

.

Treatment opinion: the unqualified pile tip shall be removed from the site and the qualified pile tip shall be replaced

.

Existing problems: the causes of the deviation of prestressed pile head: the pile positioning and setting out were not constructed according to the drawings, and the verticality was not effectively controlled during pile driving

.

Handling opinions: require the design unit to issue the design change

.

Existing problems: reinforcement cage stirrups are not densified as required

.

Causes: stirrup spacing at the end of reinforcement cage does not meet the drawing requirements

.

Treatment opinion: remove the stirrup in reinforcement cage densification area and re weld

.

Existing problems: natural foundation is soaked in water Cause: there is no necessary drainage facilities on site

.

Specification requirements: before earthwork excavation, the positioning and setting out, drainage and groundwater level lowering system shall be checked, and the walking route of earthwork transport vehicle and spoil ground shall be reasonably arranged

.

Treatment opinion: drainage as soon as possible, install drainage equipment and complete the drainage work

.

2

.

Problems in reinforcement engineering: the grade of reinforcement does not meet the requirements of the drawing (grade II reinforcement replaces grade III reinforcement) cause: the reinforcement is replaced without the consent of the design

.

Specification requirements: when installing reinforcement, the type, grade, specification and quantity of stressed reinforcement must meet the design requirements

.

Treatment opinion: replace the wrong reinforcement according to the drawing requirements

.

Existing problems: serious deviation of main reinforcement of column Causes: positioning hoop is not installed, and it is not corrected in time after pouring and tamping concrete

.

Specification requirements: allowable deviation and inspection method of steel bar installation position

.

Treatment opinion: according to the severity of the situation, it should be treated according to the specification or contact the design institute to issue a treatment plan

.

Existing problems: the stirrup of structural column is evacuated, and there is no stirrup at local position

.

Causes: column stirrups are not bound according to the drawing requirements

.

Specification requirements: when installing reinforcement, the type, grade, specification and quantity of stressed reinforcement must meet the design requirements

.

Treatment opinion: after removing the column formwork, adjust the stirrup spacing according to the drawing

.

Existing problems: the beam bottom reinforcement and waist reinforcement are not bound Cause: no acceptance before beam sinking

.

Treatment suggestion: remove the side plate of beam formwork or lift the structural beam before binding

.

Existing problems: the row spacing of stressed reinforcement exceeds the specification requirements

.

Causes: workers did not reasonably control the spacing between two layers of reinforcement

.

It is stipulated in the code that the clear distance of reinforcement between layers shall not be less than 25 mm and D

.

Treatment opinion: after the spacing of reinforcement is controlled, it is bound and fixed firmly

.

Existing problems: the main reinforcement of the secondary beam is not anchored into the main beam Causes: steel bar cutting error or workers did not install steel bar according to the specification requirements

.

Specification requirements: [16g101-1] structural beam reinforcement anchorage length requirements

.

Treatment opinion: remove the steel bar with wrong blanking and replace it

.

Existing problems: three stiffeners are not set at the folded plate according to the drawing requirements Cause: the worker did not place the reinforcing steel bar according to the drawing requirements

.

Treatment opinion: add reinforcement according to the drawing requirements

.

Existing problems: too many sleeve threads

.

Causes: the reinforcement and sleeve are not screwed firmly or the joint length is not well controlled during reinforcement processing

.

Treatment opinion: remove the unqualified sleeve and connect it again

.

Existing problems: wrong diameter of reinforcement

.

Causes: the site management personnel were not familiar with the drawings and did not deal with the lower structure of the reducer

.

Specification requirements: see 16g101-1 specification handling comments: contact the designer to issue the handling scheme

.

Existing problems: insufficient welding length of galvanized round steel Cause: the worker did not weld according to the required welding length

.

Specification requirements: round steel and round steel lap 6 times the diameter of round steel, double-sided welding

.

Treatment opinion: saw off the welding joint and weld it again according to the specification

.

3

.

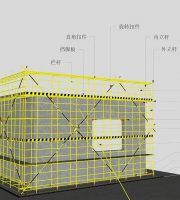

There is a problem in the formwork engineering: the upper support of the support is too long Cause: the appropriate supporting steel pipe is not selected according to the floor height

.

Specification requirements: the formwork and its support shall have sufficient bearing capacity, rigidity and stability, and can reliably bear the weight, lateral pressure and construction load of pouring concrete

.

Treatment suggestion: select appropriate support according to the floor height and adjust the jacking extension length

.

Existing problems: lack of horizontal tie rod in formwork support system

.

Causes: the construction unit did not carry out the construction according to the formwork construction scheme

.

Specification requirements: the formwork and its support shall have sufficient bearing capacity, rigidity and stability, and can reliably bear the weight, lateral pressure and construction load of pouring concrete

.

Treatment opinion: add horizontal tie rod according to the formwork construction scheme

.

Existing problems: the joint of formwork installation is not strict Causes: construction workers are not careful formwork, formwork size is not regular

.

Specification requirements: the joints of formwork shall not leak slurry; Before pouring concrete, the wooden formwork shall be watered and wetted, but there shall be no ponding in the formwork

.

Treatment opinion: fill the gap with tie wood, and then close the gap with adhesive tape

.

Existing problems: causes of formwork support on floating slab: it is easy for construction workers to support formwork on floating slab

.

Specification requirements: the formwork and its support shall have sufficient bearing capacity, rigidity and stability, and can reliably bear the weight, lateral pressure and construction load of pouring concrete

.

Treatment opinion: re support the formwork from the bottom

.

Existing problems: there is no cleaning hole in the template cutting

.

Causes: the construction workers did not cut the template according to the requirements

.

Specification requirements: before pouring concrete, the sundries in the formwork shall be cleaned up

.

Treatment opinion: fill the gap with tie wood, and then close the gap with adhesive tape

.

4

.

Problems in concrete engineering: serious expansion of structural concrete formwork Causes: the formwork is not firmly installed, and the formwork is expanded when the concrete is vibrated

.

Specification requirements: deviation of section size of concrete appearance inspection lot is + 8, – 5 treatment opinion: chisel the expansion formwork part before repairing

.

Existing problems: causes of exposed reinforcement in concrete drilling: exposed reinforcement caused by excessive drilling after concrete formwork expansion

.

Specification requirements: the appearance quality of cast-in-place structure should not have serious defects

.

Treatment opinion: according to the severity of the problem

.

Existing problems: structural column sanding Causes: the structural column head formwork did not clear the water before pouring concrete

.

Specification requirements: the appearance quality of cast-in-place structure should not have serious defects

.

Treatment opinion: contact the design institute to issue a treatment plan and deal with it according to the plan

.

Existing problems: the exposed reinforcement honeycomb of concrete slab is serious Cause: no protective layer cushion block is placed under the slab reinforcement

.

Specification requirements: the appearance quality of cast-in-place structure should not have serious defects

.

Treatment opinion: contact the design institute to issue a treatment plan and deal with it according to the plan

.

Existing problems: dislocation of upper and lower layers of structural column Cause: inaccurate installation of lower formwork

.

Specification requirements: the cast-in-place structure should not have the size deviation that affects the structure performance and use function

.

Treatment opinion: contact the design institute to issue a treatment plan and deal with it according to the plan

.

Existing problems: slag inclusion in beam bottom concrete Cause: the formwork is not cleaned up before pouring and tamping concrete

.

Specification requirements: the appearance quality of cast-in-place structure should not have general defects

.

Treatment suggestion: clean up the slag inclusion and deal with it according to the severity of slag inclusion

.

Existing problems: beam concrete cracking Causes: the formwork of the lower layer of the structure is removed in advance

.

Specification requirements: the appearance quality of cast-in-place structure should not have general defects

.

Treatment opinion: contact the designer for treatment

.

Existing problems: serious concrete holes Causes: insufficient vibration during concrete pouring, or serious leakage of column formwork

.

Specification requirements: the appearance quality of cast-in-place structure should not have serious defects

.

Treatment opinion: according to the severity of the problem

.

5

.

Problems in safe and civilized construction: the flat bridge of external scaffold construction is not fully paved Causes: the external scaffold construction flat bridge is not fully paved or removed by workers during construction

.

Specification requirements: floor type external scaffold inspection score table requirements: scaffold board should be fully paved

.

Treatment opinion: lay flat bridge slab immediately, and do not walk on the flat bridge before the scaffold is fully paved

.

Existing problems: there is no protection at the edge of stairs Causes: weak safety awareness, artificially reduce the cost of safety investment

.

Specification requirements: protective measures must be set for edge operation.

.