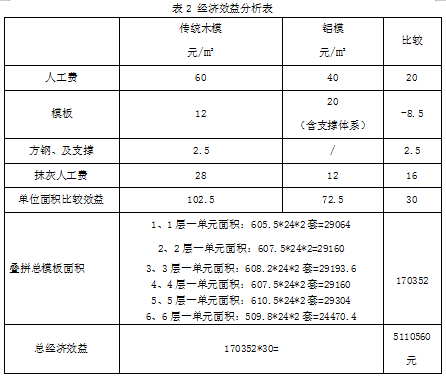

In construction engineering, formwork is an important turnover material, so the selection of formwork has an important impact on the cost control, construction progress and project quality of the whole project

.

There are many formwork materials available in the market, such as wood formwork, steel formwork, composite formwork, aluminum alloy formwork, etc

.

In the 6-10 group project of the first phase of Sino German future city, all the row and stack buildings are passive buildings, which have strict requirements for the quality

.

The shape, size and location accuracy of the components after the concrete forming have more stringent requirements, so as to prevent the influence on the subsequent construction of the later temperature maintenance, doors and windows, fresh air fan, hardcover and other units

.

Therefore, the formwork is required to have sufficient strength Stiffness and stability

.

Considering the actual situation of the project, there are 11 townhouses, with a total of 48 units and the same house type, so it is decided to use aluminum formwork

.

The 6-10 group project of China Germany future city phase I is located in the west side of line 32 of China Germany ecological park and the south side of line 17 of ecological park

.

The total construction area of the project is 114808.07 m2, the aboveground construction area is 76089.54 m2, and the underground construction area is 38718.53 m2

.

There are many individual projects, including 11 townhouses, with a total of 48 units and the same house type

.

Feasibility analysis on the application of stacked aluminum mold: horizontal flow construction technology of stacked aluminum mold 1

.

Preliminary planning and preparation stage 1

.

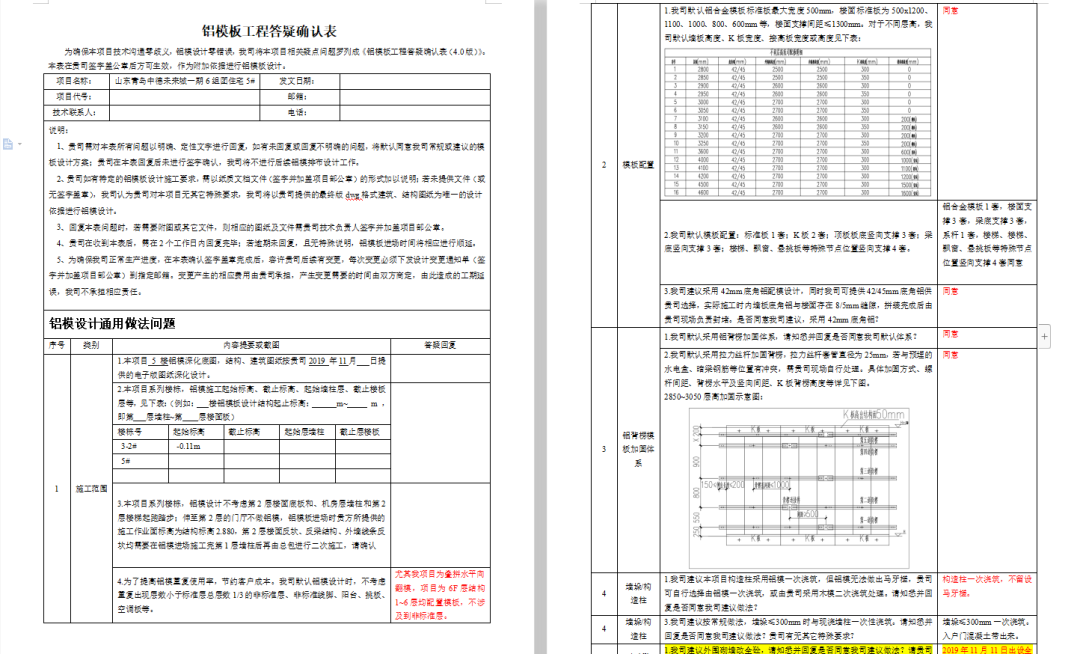

Drawing optimization and detailed design of aluminum mold matching in the drawing detailed design stage, the technical personnel of both parties shall participate in the joint design stage, and the technical personnel of aluminum mold manufacturer shall establish the structure and architectural model according to the project drawings, Find out the problems in the drawings through review, and feed back the summary of the existing drawing problems to the project technical personnel, and then the project technical personnel will connect the owner, the supervisor and the design institute

.

After the final confirmation, the joint review table of drawing problems will be formed as an important basis for drawing change and construction operation

.

Then the designer of the aluminum formwork manufacturer shall carry out the detailed design and assembly drawing of the aluminum formwork according to the construction drawings, design specifications and the joint review record of drawings

.

3-D structure model aluminum mold 3-D assembly model drawing joint review aluminum mold deepening confirmation aluminum mold deepening design assembly drawing 2

.

Aluminum mold team configuration according to the level flow construction technology of stacked aluminum mold unit, the site grid is divided into 12 construction groups, each unit layer fixed construction group, the number of personnel in each group is fixed at 6 ~ 8; The aluminum formwork installation team enters the site in batches: after the aluminum formwork materials enter the site, the first batch of personnel enter the site, 12-14 people, mainly responsible for the installation of two sets of aluminum formwork on one floor; After the first layer of formwork is removed, the second batch of workers enter the site, mainly responsible for the assembly of the second layer of unit layer aluminum formwork, and so on to the installation of the sixth layer of unit layer aluminum formwork

.

After the workers enter the site, a total of 72 ~ 96 people

.

Organization chart of aluminum formwork installation personnel 3

.

Material preparation aluminum formwork manufacturers produce and process aluminum formwork according to the deepening drawings, and enter the site in six batches according to the actual construction progress

.

Before entering the site, they need to complete the pre assembly, number and pack after the assembly is qualified, and then the manufacturer sends technicians to guide the aluminum formwork team to carry out the on-site assembly

.

Aluminum mold material configuration: according to the actual requirements of the site, two units of aluminum mold should be configured, each unit has 6 layers, and 6 sets of aluminum mold should be configured

.

Each unit layer is equipped with a set of standard board; 2 sets of k-plates; 3 sets of vertical supports at the bottom of the top plate; 3 sets of vertical supports at the bottom of the beam; There are 4 sets of vertical supports at special nodes such as stairs, bay windows and cantilever slabs

.

2

.

In the construction stage, there are 11 overlapping buildings with 48 identical units

.

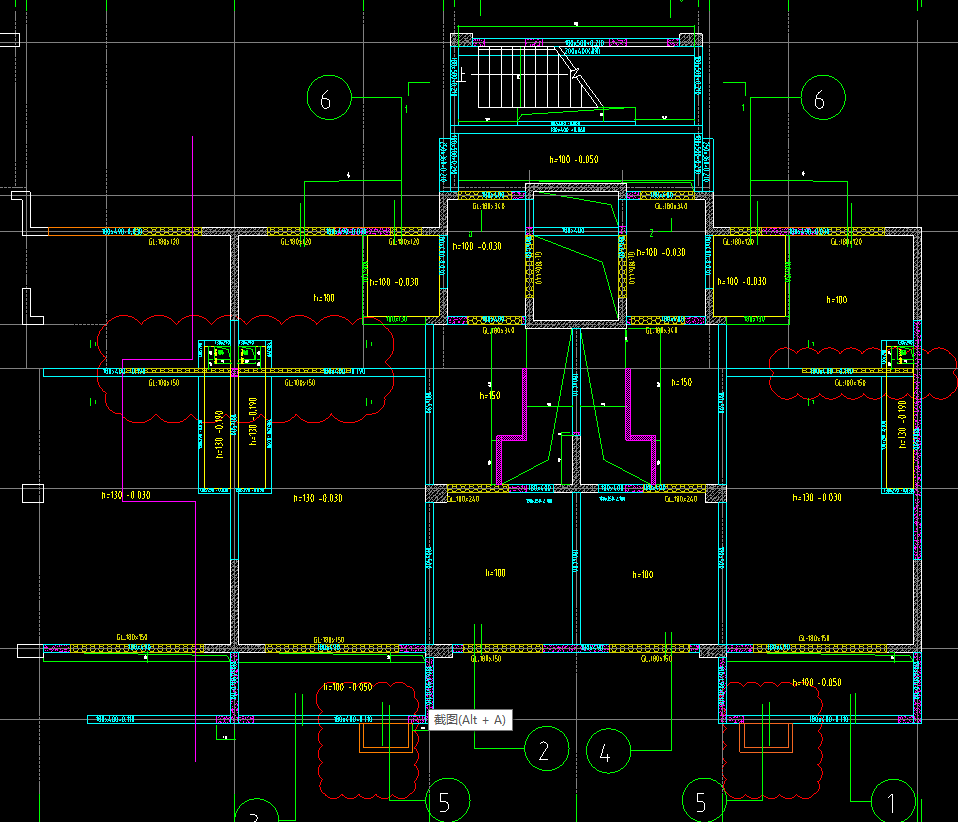

Layout of aluminum formwork floor 1

.

Process survey and setting out → installation of wall column reinforcement (wall column water and electricity construction) → installation of wall column aluminum formwork → installation of beam aluminum formwork → installation of floor aluminum formwork → installation of beam slab reinforcement (beam slab water and electricity installation) → final reinforcement inspection → concrete pouring → transfer of aluminum formwork to the next unit → transfer of aluminum formwork to the next building after the main structure of the same floor is completed

.

2

.

The construction idea of horizontal circulation of the same unit type of aluminum formwork is different due to the different floor layout and unit composition on site, and the facility joints are reserved for each unit; One set of aluminum formwork and three sets of supporting rods are provided for each unit of 1 ~ 6 floors, and one set of aluminum formwork is provided separately for the left and right gables of each unit, so as to ensure the reasonable conversion of the location of each building gable, facilitate the turnover use, and speed up the construction progress on site

.

The schematic diagram of construction joint reservation is the same as that of horizontal flow transportation of the same unit in the same building

.

The three-dimensional effect picture is the same as that of horizontal flow transportation of the same unit in the same building

.

The schematic diagram of horizontal flow construction of the same unit in the same building

.

3 The multi-storey building with more single buildings is equivalent to transforming the vertical turnover of aluminum formwork into horizontal turnover of high-rise building

.

By planning in advance and deepening the design of aluminum formwork, under the premise of ensuring safety, quality and progress, the on-site construction tends to be more reasonable, fast and efficient

.

It greatly reduces the use of labor, improves the work efficiency, and realizes the win-win cooperation between the project and the team

.

This construction technology provides an effective reference for the implementation of similar projects in the future, and has achieved good economic and social benefits( The article comes from the network media, if there is infringement, please contact to delete) integrity, pragmatic service industry for the ninth year registration / cooperation consultation, scan the QR code below to solve your needs, first-hand test training project plate 1: BIM Engineer (human society, industry and information technology, graphic society and other systems) plate 2: formal title evaluation (primary, intermediate, senior) plate 3: Education Promotion (technical secondary school, junior college Upgrading from junior college to undergraduate course 4: Senior prefabricated building manager 5: Senior Project Manager of EPC 6: technicians and other posts, five members of water conservancy 7: eight members (constructors, safety officers, material officers, documenters, Plate 8: intermediate “fire fighting equipment operator” examination 4 times a year plate 9: Ministry of industry and information technology education and examination center “Vocational and technical certificate”, such as: network engineer, computer-aided designer, 3D animation designer, multimedia designer, graphic designer, computer network design engineer, e-commerce engineer, Web Designer Internet of things Technology Application Engineer..

.

Etc

.

10: National Vocational Information Network Talent warehousing certificate, docking with the professional registration hotline of various industries; 13611186885 (wechat number) Mr

.

Yang.

.