Wujiagang Yangtze River Bridge is a key project for Yichang to build a new pattern of development on both sides of the river, promote the overall development of Jiangnan and build a regional business center, with a total investment of 3.366 billion yuan

.

The total length of the main line of the project is 2.813km, which starts from Jiangcheng Avenue in the south, crosses Yangtze River and yuewulin Road, and ends at Huaxi road

.

Aijia interchange and Wulin Road interchange are set at the starting point and crossing Wulin Road respectively

.

The main span of the main bridge is 1160m orthogonal special-shaped deck steel box girder suspension bridge with a width of 31.5m, realizing one span across the Yangtze River

.

The main tower is a portal frame structure, and the anchorage forms are north bank tunnel anchor and south bank tunnel anchor

.

After the Wujiagang Yangtze River Bridge is completed and opened to traffic, it will realize the closed loop of the middle ring road in the urban area, and the three inner and outer rings will take shape

.

The construction of Yichang “three vertical and five horizontal” expressway grid bureau is of great significance to expand the urban skeleton, improve the layout of urban road network, and promote the construction of Yichang modern mega city and regional central city in the middle and upper reaches of the Yangtze River

.

2

.

BIM application background in recent years, BIM Technology Theory and technology development is in a period of rapid development

.

It has been widely used in the field of construction engineering, and its application in bridge engineering has also attracted more and more attention

.

Chongqing Yongchuan Yangtze River Bridge, Zhaoqing Yuejiang bridge, Feiyun River cross sea bridge, Qatar Doha bridge and other key bridge projects have also changed from the integration of design and construction to the integration of design and construction We have carried out beneficial exploration and practice in the aspects of detailed design of complex nodes, collision check, scheme comparison, 3D visualization disclosure, duration simulation, management and operation platform

.

BIM Technology is a typical professional application in the field of bridge engineering

.

It is necessary to carry out relevant platform selection, modeling standards, processes, especially the research on application value landing in combination with the characteristics of bridge engineering

.

Compared with construction engineering, bridge engineering generally focuses on structural design, involving relatively few other professions, and the shape and stress behavior of components are relatively complex

.

Construction methods, processes and processes have a great impact on the structural stress

.

At the same time, the service environment of bridge engineering is relatively poor, and the focus of later operation and maintenance is structural safety and durability

.

3

.

BIM application purpose BIM management technology is adopted in the construction of this project, which mainly refers to the application of BIM Technology in the existing construction industry, so as to establish a BIM application mode in line with the actual business management and control needs of bridge construction site, and improve the project construction quality and refined management level

.

4

.

BIM field application 4.1 collaborative operation in bridge engineering project management, there are many participating units, the construction unit, construction unit, design unit, supervision unit and other related subjects need to coordinate with each other, and there are many cross work in the work process, which increases the difficulty of communication and coordination, and restricts the improvement of project quality, progress and cost

.

Through the BIM Technology as the center of the project management cloud platform, can greatly improve the communication efficiency of the participants, improve the project management decision-making ability

.

4.2 there are many structural components related to the progress simulation bridge construction, and the construction process is relatively complex

.

At the same time, the bridge construction project management is a real-time dynamic process

.

The traditional passive management mode is not suitable for the project management process of bridge construction

.

BIM Technology can establish the three-dimensional model of each stage of the construction process, make the management of the construction process more refined, and let the construction management personnel make more reasonable decisions and arrangements

.

BIM Technology is used to combine the construction progress with the three-dimensional model to simulate the whole construction process and construction progress of the bridge

.

The difference between the actual progress and the planned progress can be displayed very intuitively, which is convenient for the project management personnel to adjust the on-site production deployment according to the progress deviation

.

In addition, the UAV aerial photography technology is used to grasp the actual progress of the construction site in real time, and the daily aerial photography situation is fed back and compared with the progress in the model in the progress control management

.

4.3 construction simulation animation some dangerous projects use three-dimensional model for simulation

.

In the process of pier construction, the template will swing during the process of template hoisting

.

When the amplitude of template swing is large, it will pose a greater threat to the site personnel

.

BIM Technology is used for simulation to ensure the personal safety of the site personnel

.

In the process of pier body simulation construction, we can also use the software Revit to identify the construction safety, find the unreasonable phenomenon in the design in time, and adjust the triangular support platform in time when the operators have difficulties in operation and may fall

.

4.4 visual disclosure in bridge engineering, there are many kinds of embedded parts in the main tower (such as inspection ladder, elevator, conveying pipe and fixed embedded parts of tower crane, etc.), which are visualized in the form of three-dimensional model, so as to facilitate the disclosure of workers before construction, which is more intuitive and more figurative

.

Combined with the visual construction scheme simulation animation and three-dimensional renderings, the three-dimensional visualization disclosure of the key parts of the facilities for the project management personnel and operators is carried out, so as to avoid the wrong construction caused by the wrong understanding of the drawings and technical schemes

.

At the same time, the time of looking at the drawings is saved, the common awareness is improved, the communication efficiency is improved, and the accurate and orderly development of the process is ensured

.

4.5 collision inspection: the main tower structure of Wujiagang Yangtze River Bridge is complex, the internal reinforcement is dense, the external rigid skeleton is used as support, various embedded parts, bellows and other components positioning accuracy requirements

.

In the traditional construction management, it is difficult to find the collision problem between different components in the two-dimensional plane drawings, which leads to rework, resulting in a great waste of cost and delay of construction period

.

By using BIM software and setting the corresponding collision inspection rules, the collision points that meet the collision inspection conditions can be quickly found, and the collision report can be generated, so as to find the internal collision problems in advance, achieve the three-dimensional verification effect of the design drawings, and avoid the delay or rework of the construction period

.

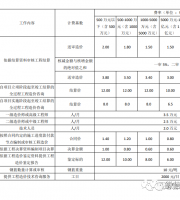

4.6 engineering quantity statistics: the tunnel anchor of Wujiagang project is a wedge-shaped structure with small front and large back, and the inclination angle of axis is 40 °。 According to the actual construction segment division, 3D modeling of the project is carried out to solve the problem that the traditional manual calculation is difficult to quickly and accurately calculate the actual quantities of mass concrete construction, and assist the project in the quantity control and budget settlement

.

At the same time, the use of BIM Technology can be more refined management of construction materials, construction machinery, construction personnel, improve the utilization of people, materials, machinery

.

For example, the BIM model can read the amount of reinforcement and concrete in each part and stage of the bridge construction process at any time, carry out digital cutting, provide technical reference for quota picking, and save cost and resources

.

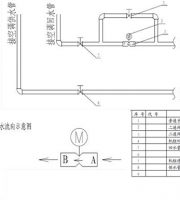

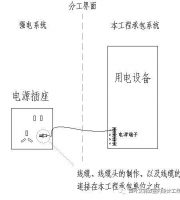

4.7 the docking of detection and monitoring system combines the three-dimensional model with each monitoring point, and sets different types of sensors to associate with the monitoring system, so as to visually display the stress changes in the monitoring process in three dimensions

.

By associating the BIM model with the intelligent monitoring platform independently developed by the Third Bureau, it can receive all kinds of operating parameters in real time, display and give early warning, and remotely monitor the operation status of the platform in real time, so as to protect the healthy and safe operation of the platform

.

4.8 design and construction of temporary components Wujiagang project relies on the technical advantages of super high-rise construction platform of the Third Engineering Bureau, and independently develops the exclusive construction platform for bridge tower construction – “integral adaptive double formwork construction platform”, which is widely concerned by the community

.

According to the construction scheme, relevant design drawings, specifications and other data of the adaptive double formwork construction platform, the three-dimensional modeling of the formwork system of the adaptive double formwork construction platform is carried out, and the construction conditions of each section of the formwork system are verified by the comprehensive analysis of the tower crane lifting performance, construction section division, double formwork circulation operation, construction safety and other factors, Optimize and form the final mold base system for field use

.

The three-dimensional model is imported into Midas, SOLIDWORK and other structural checking software to carry out the overall calculation of the formwork structure, the partial checking calculation of the frame, the structural calculation of the supporting system, the hydraulic system, the tower column structure and the formwork calculation.

.