The construction industry is an accident prone industry, with long construction production cycle, large mobility of workers, more outdoor high-altitude operations, more manual operations, heavy labor, large product changes, poor regularity, various types of construction machinery, uneven safety performance, and many uncertain risk factors

.

The hidden dangers in high-altitude operation, cross operation, foundation operation and lifting machinery are particularly prominent, which are mainly reflected in four aspects: falling from height, object strike, earthwork, foundation pit collapse and lifting machinery injury

.

The main causes of the accident are as follows: the special construction scheme is not prepared before the construction or the construction is not carried out according to the approved special construction scheme; In the process of construction, the protection of work at height is not in place; The erection of scaffold is not standard; The support of foundation pit and formwork engineering is not firm; Improper use of lifting machinery and equipment, etc

.

In order to reduce accidents, we should improve our own safety awareness, strengthen the safety production management system, improve the safety production responsibility system, promote the safety production management, and regularly carry out safety education and training for employees

.

In view of the above four major injury accidents, it is necessary to carry out special rectification, take effective measures to eliminate safety hazards and effectively reduce casualties

.

Here, we will analyze the causes and preventive measures of the four accidents: 1

.

The construction workers themselves suffer from diseases that are not suitable for working at height, such as hypertension, heart disease, anemia, etc; 2

.

The safety awareness of construction personnel is poor, and they have no self-protection awareness, such as sitting on the fence to rest and sleeping on the scaffold; 3

.

Safety accidents caused by bad weather, such as: sudden strong wind and rainstorm, high temperature and heat stroke in summer, fainting and falling, slipping and falling in winter, rainy season and frost; 4

.

The quality of safety protection articles and materials does not meet the specification requirements, or fail to wear and use as required; 5

.

Personnel fall due to inadequate protective measures at the entrance and edge

.

Measures to prevent falling accidents from height: 1

.

Strict physical examination must be carried out for the personnel working at height before entering the site, and they shall be registered according to the real name system, and they shall be checked regularly during the construction period; 2

.

Carry out strict three-level safety education, training and disclosure for construction personnel entering the site, enhance safety awareness, provide self-protection ability, and consciously abide by laws, regulations, specifications and various safety production management systems; 3

.

In case of strong wind and dense fog above level 6, it is not allowed to work at height; Reliable anti-skid, anti cold and anti freezing measures must be taken in rainy and snowy days; Water, ice, frost and snow should be removed in time; 4

.

Purchase qualified safety protection articles, use them within the validity period, and correctly wear and use them as required; 5

.

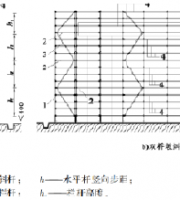

Warning signs and protective railings shall be set at dangerous sections or beside pits and wells, and red light warning and construction lighting shall be added at night; Safety helmets, safety belts, safety ropes, safety nets, etc

.

must be worn and safety protection measures must be strictly implemented for portal, edge, cross operation, climbing operation and hanging operation

.

Object strike accident object strike accident causes 1

.

Unreasonable labor organization, three-dimensional cross operation and no effective isolation and protection; 2

.

There is no warning line in the demolition project, and protective fence and isolation fence are set around the demolition project, and there is no special person to guard it; 3

.

The wind rope and ground anchor are not firmly buried or the wind rope does not meet the specification requirements; 4

.

The lifting operation did not strictly comply with the “ten no lifting” safety management regulations; 5

.

Throw construction materials, sundries, garbage or tools and small materials from high places; 6

.

Building materials on buildings, structures and scaffolds are stacked unsteadily, too much, too high and close to the edge, causing falling injury

.

Measures to prevent object strike accidents: 1

.

Before the demolition project construction, special construction scheme shall be prepared, approval procedures shall be performed correctly, protective barriers and barriers shall be erected as required, warning signs and protective nets shall be erected; 2

.

Ensure the quality of safety protection articles, timely replace and update the old and damaged safety protection articles; 3

.

Regularly check the firmness of the ground anchor and the use of the wind rope; 4

.

Educate the construction personnel of lifting operation to operate in strict accordance with the safety technical operation regulations of lifting operation; 5

.

Correct bad working habits and strictly prohibit throwing construction materials, explosives, garbage and tools down or up; 6

.

Clean up the materials stacked on the scaffold, so as not to be overweight, not to be ultra-high, not to the side, not to be piled up

.

Causes of earthwork, foundation pit collapse accident earthwork and foundation pit collapse accident 1

.

No special construction scheme was prepared before the project construction, or the approval procedures were not performed correctly; The construction personnel did not carry out the construction according to the approved special scheme; 2

.

The construction personnel are lack of safety awareness and self-protection ability, command against rules and take risks; 3

.

The effective dewatering and drainage measures are not set around and at the bottom of the foundation pit, which leads to the collapse of the foundation pit caused by water leakage; 4

.

The construction materials are randomly stacked around the foundation pit (groove), side slope and foundation pile hole; 5

.

The construction machinery is not operated and parked as required, and it is too close to the foundation pit (groove) slope and foundation pile hole; 6

.

There is a lack of inspection and maintenance of the construction site during the rainy season, winter and thawing period

.

Measures to prevent earthwork and foundation pit collapse accidents 1

.

Organize the preparation of special construction scheme, formulate special safety technical measures, and correctly perform the approval procedures in strict accordance with the construction safety technical standards, specifications and relevant documents of the Ministry of housing and urban rural development

.

The special scheme of more dangerous divisional and sub divisional projects exceeding a certain scale shall be demonstrated by experts in strict accordance with the procedures; 2

.

Before the excavation of foundation pit, it is necessary to do a good job of water lowering (drainage) and take protective measures; 3

.

If all kinds of building materials are stacked at the side of foundation pit (groove), slope and foundation pile hole, the specified safe distance shall be ensured; 4

.

The distance between all kinds of construction machinery and foundation pit (groove), slope and foundation pile hole shall be determined according to equipment weight, foundation pit (groove), slope and foundation pile support and soil conditions, and shall not be less than 1.5m; 5

.

During construction in rainy season, winter and thawing period, comprehensive inspection and maintenance shall be carried out on the construction site to ensure smooth drainage and no abnormal conditions before construction; 6

.

During mechanical excavation of earthwork, operators are not allowed to enter the scope of mechanical operation for cleaning and slope making

.

Hoisting machinery injury accident causes of hoisting machinery injury accident 1

.

Mechanical equipment overload operation or “sick” work; 2

.

Drivers without license, lack of experience, numbness of mind, illegal operation; 3

.

The lifting equipment is not equipped with force distance limiter, height limiter, weight limiter and electrical interlock switch light safety device; 4

.

Construction elevator overload, overload operation caused falling accident

.

Measures to prevent injury accidents of lifting machinery: 1

.

Regular maintenance and repair of lifting machinery and equipment should be carried out to keep them in good operation condition; 2

.

Drivers should work with certificates, select experienced drivers, strengthen the education of operators, strictly abide by operating procedures, and strictly prohibit illegal command and operation; 3

.

The safety device of lifting equipment can only be used after debugging; 4

.

Overloading is prohibited, emergency plans for falling accidents are organized, and training and emergency drills are regularly organized

.

Therefore, construction enterprises must conscientiously follow the “construction safety inspection standard” jg59-2011, strengthen the safety production inspection and on-site safety management of enterprises, comprehensively strengthen safety training and education, and constantly improve the safety awareness, sense of responsibility, technical level and safety quality of employees

.

Through the strict safety production management of the whole process, all-round and full participation, the “four major injuries” of construction accidents are reduced to the lowest level, and the interests of enterprises and the safety of construction personnel are effectively protected

.

Material from the network, if there is infringement, please inform delete.

.