The vertical load-bearing reinforcement in the column shall not be less than 4 for corner column and side column ф 14; For the center column, it shall not be less than 4 ф 12; 6

.

In order to effectively control cracks, it is necessary to understand the manifestations and main causes of cracks: manifestations: horizontal cracks, vertical cracks and inclined cracks; Main causes: uneven settlement, temperature difference, material shrinkage, construction factors, etc

.

1

.

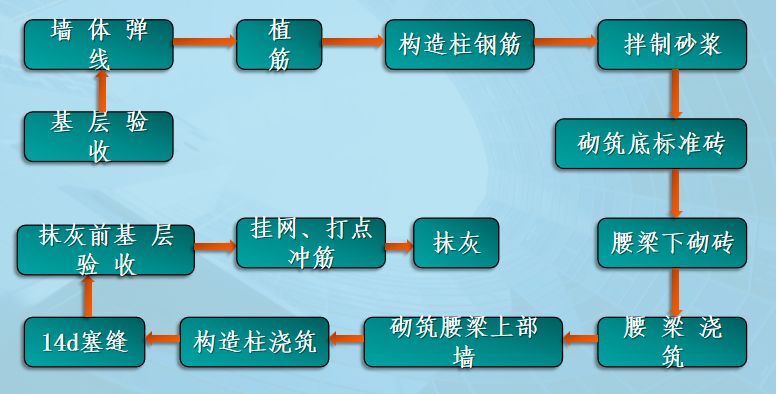

Aiming at the formwork free construction of structural columns, the animation demonstration of process flow produced by BIM studio of technology and Quality Department of North China company of China Construction Seventh Bureau catches all five situations of structural columns, that is, comprehensive and clear ☟ 1 key points for quality control of secondary structure construction, primary and secondary structure construction process and control points 1

.

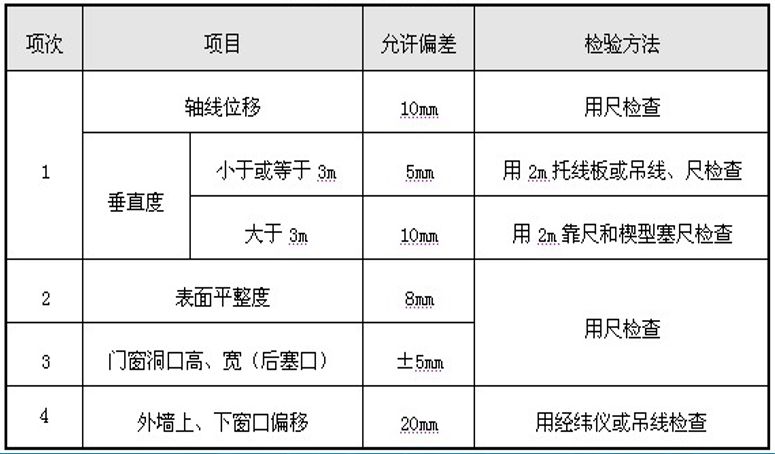

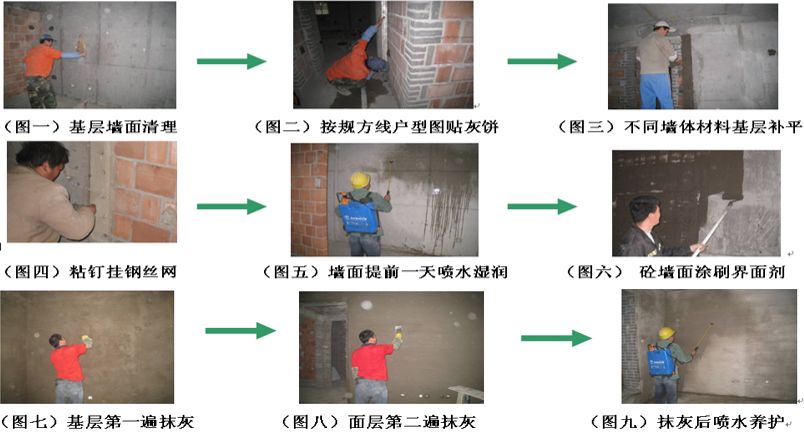

Key points for base course acceptance and wall setting out control: floor laitance of masonry base course Clean up the residue and snap the line

.

II

.

2

.

The sensory forming quality is good, the construction period is saved, and the construction progress of structural column and masonry can be carried out at the same time

.

Waist beam (sill beam) – control points 1) when the wall height is greater than 4m, a concrete ring beam with a height of not less than 120mm and the same width as the wall shall be added in the middle; 2) The full-length cast-in-situ reinforced concrete slab strip shall be set at the sill elevation of each floor

.

11

.

The drilling shall be cleaned with a blower to ensure the drilling depth

.

18

.

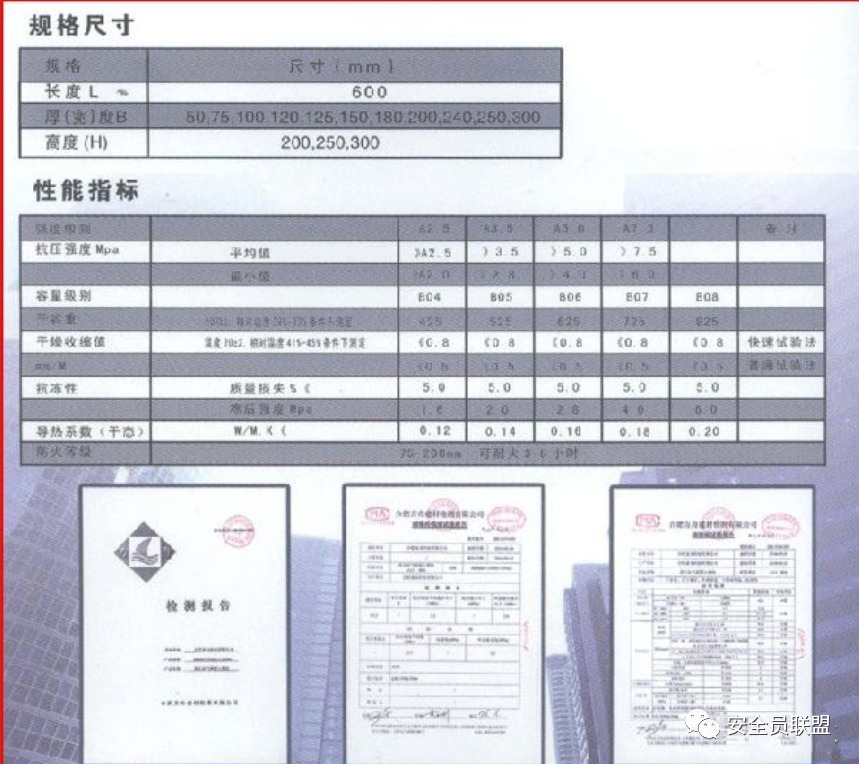

Aerated concrete block – quality requirements 1) the strength grade of masonry mortar and block shall meet the design requirements

.

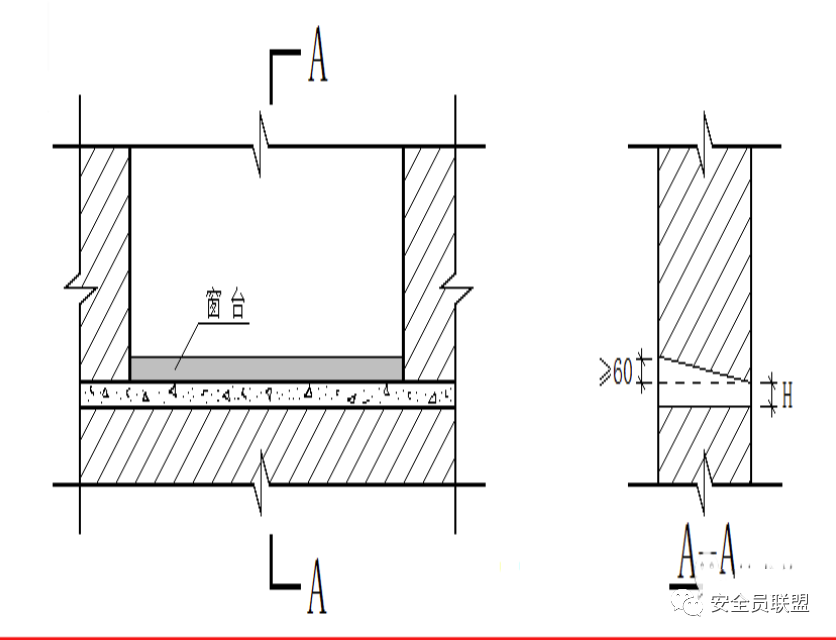

Waist beam (sill beam) – the sill beam requires that the top surface of the sill should be cast into an inclined plane with an internal height of high and an external low, and the height difference of more than 60mm

.

Structural column – detail 8

.

The spacing is 100mm, which should be adopted for general parts ф 6

.

Spacing: 200mm; 7

.

Tie bars shall be constructed as per 80mm, with spacing of 500mm

.

After the reverse cutting position is determined, chisel the connecting parts of floor and wall

.

The mortar joint shall be leveled before and after the final setting of masonry mortar; 14

.

Caulking – key points of brick control: when the infilled wall is built close to the beam bottom and slab bottom, it shall be tightened at an angle of 45 ° ~ 60 °; During the patching, the vertical joints on both sides shall be filled with high-strength cement mortar

.

One tie bar is set every 120mm wide, two tie bars are set at 120 ~ 240, one tie bar is set at < 120 and three tie bars are set at > 240; 15

.

Improper treatment of brick mixing interface is easy to cause quality risks such as hollowing and cracking of later plastering

10

.

Proper watering shall be done before masonry

.

17

.

Caulking — key points of mortar (fine aggregate concrete) control: when the infilled wall is built close to the beam bottom and slab bottom, after the infilled wall is built and an interval of at least 7 days, it shall be chamfered or caulked with fine aggregate concrete

.

5

.

3

.

The manufacturer of the required embedded reinforcement glue shall be selected in advance to ensure qualified performance and simple operation

.

Wall masonry – assembly requirements 2) infilled wall masonry shall be staggered, and the masonry length of aerated concrete blocks shall generally not be less than 1 / 3 of the block length

.

At the same time, after forming, the deviation between the surface flatness of the structural column and the brick masonry is small, and there is no treatment problem of the double-sided tape after the construction of the traditional structural column, which reduces the quality risk of hollowing and cracking in the later plastering construction

.

Structural column – stirrup requirements 1) stirrup of structural column should be used within 500mm above and below the floor ф 6

.

Wall masonry – mortar joint requirements 3) the horizontal mortar joint of infilled wall masonry shall be straight, and the mortar fullness calculated according to the net area shall not be less than 80%

.

The vertical through joint shall not be greater than 2 blocks; 13

.

Wall masonry – brick arrangement and masonry requirements 1) during the masonry of infilled wall, the blocks shall be pre selected and pre arranged, the dirt on the block surface shall be removed, and the blocks with unqualified appearance quality shall be removed

.

Plant Reinforcement – key points of embedded depth control: the tie bar between masonry and column or shear wall, the connection between lintel, ring beam, cast-in-situ slab reinforcement and structure, and the connection between structural column vertical reinforcement and upper and lower layers shall adopt the method of planting reinforcement, the structural adhesive shall adopt qualified structural adhesive, and the embedded depth shall not be less than 12D( ф 6

.

Wall masonry – tie bar requirements 4) the connection between infilled wall masonry and structure shall be set every 500 intervals ф 6

.

In order to avoid crack, it is necessary to consider from the aspects of design, material and construction

.

The number of tie bars is set according to the wall thickness

.

The post planted tie bar extends 700 beyond the edge of structural wall column

.

The mixed mortar shall be used up in a short time as soon as possible to avoid too long and final setting of mortar

.

Aerated concrete blocks shall have certificates and test reports when entering the site; Samples shall be taken on site and sent to a qualified testing laboratory for re inspection

.

The vertical mortar joint shall be filled with mortar to make the masonry mortar full

.

The thickness of the slab strip shall not be less than 60mm, the concrete strength grade shall not be less than C20, and the longitudinal reinforcement shall not be less than 3 ф 8 (if required by the design, it shall be configured in strict accordance with the design requirements)

.

During wall masonry, lines (horizontal and vertical) shall be hung, and the flatness and verticality of masonry shall be corrected with guiding ruler at any time; 12

.

9

.

The side line of infilled wall and the position line of door and window openings shall be accurate, and the deviation shall be controlled within the allowable range of the specification

.

Bottom – key control points of concrete waterstop: Waterproof rooms such as kitchen and bathroom, exterior wall and air conditioning board shall be provided with concrete with a height of no less than 200mm

.

2) Aerated concrete blocks shall not be mixed with other materials

.

The plumpness of vertical joints shall not be less than 80%

.

Inspection method: check the certificate, test report and retest report of the block; Test report of mortar test block

.

During construction, the concrete pouring and vibration are not dense, the surface forming quality is poor after formwork removal, and the construction progress of secondary structure often affects the internal and external plastering progress

.

For masonry structure, crack is the biggest quality defect

.

3) The general dimension allowable deviation of aerated concrete block shall comply with the following table: three common quality control points

.

Bottom — control points of standard brick: when building block infilled wall, 3 standard bricks shall be built at the bottom of the wall

.

16

.

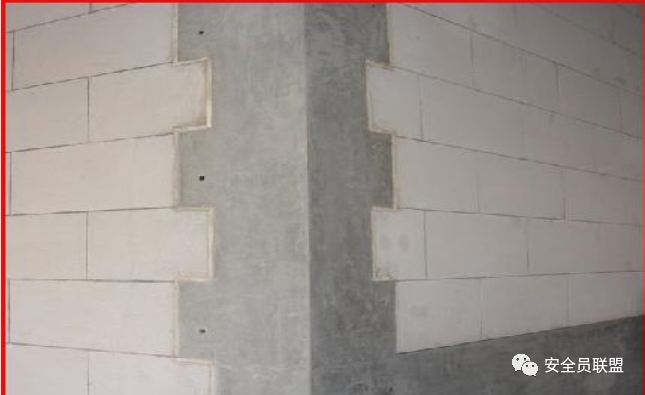

Construction column construction process 4, construction column – section and template require the wall on both sides of the construction column to set up a horse’s rack, adopt the first step backward method, the masonry side of the horse’s mouth should be lined with double-sided foam adhesive tape, the thickness is not less than 5mm, the strength level of the concrete used for the structural column is C20, and the masonry formwork should have reliable reinforcement and support measures

.

Structural column — setting position and construction process: position where structural column needs to be set: 1) Interface of different materials; 2) Junction of internal and external walls; 3) The wall length is greater than 4m; 4) Unconstrained end of masonry; 5) The opening width is greater than 2m

.

2

.

Structural column – concrete and reinforcement requirements 1) the concrete strength grade of structural column shall not be lower than C20; The strength grade of masonry mortar shall not be lower than M5; 2) The section size of structural column shall not be less than 240mm × 240mm, the thickness shall not be less than the wall thickness, and the section width of corner column and side column can be increased appropriately

.

Source: North China branch of China Construction Seventh Engineering Bureau and Zhuolong construction have many traditional construction procedures of structural column: binding of structural column reinforcement → leaving horse tooth tenon for masonry construction → pasting double-sided tape → formwork erection → concrete pouring → formwork removal

.

Aerated concrete block – mortar joint requires that the vertical joints of the upper and lower skin of the aerated concrete block shall be staggered with each other; When cement mortar is used, the thickness of horizontal mortar joint should be 15mm and the thickness of vertical mortar joint should be 20mm

.

Knowledge of aerated concrete blocks

.

The formwork free construction process of structural column is simple: binding of structural column reinforcement → construction of U-shaped hollow block with masonry → concrete pouring

.

Key points of mortar mixing control: overnight mortar shall not be used for masonry mortar, and water shall not be added casually during use

.

Material requirements – brick and sand 1) medium and coarse sand shall be used for masonry mortar, and mountain sand and mixed powder are strictly prohibited.

.

The embedded reinforcement must undergo the pull-out test, and the subsequent construction can be carried out only after it is qualified

.

Aerated concrete block – Forbidden Part 1) alternate dry and wet parts or wet parts; 2) Underground parts of buildings; Scaffold holes shall not be set for aerated concrete blocks, and openings, pipes and grooves required by the design shall be reserved and embedded; 3

.

It is strictly prohibited to flush and fill the joint with water, and there shall be no false joint, blind joint and transparent joint

.

1

.