After the appearance inspection is qualified, 2 bars shall be selected from each batch for tensile test

.

The anchorage (or connector) suitable for high-strength prestressed reinforcement can also be used for low-strength prestressed reinforcement

.

In general engineering, reserved holes can be made by steel pipe core pulling, rubber pipe core pulling or metal telescopic sleeve core pulling

.

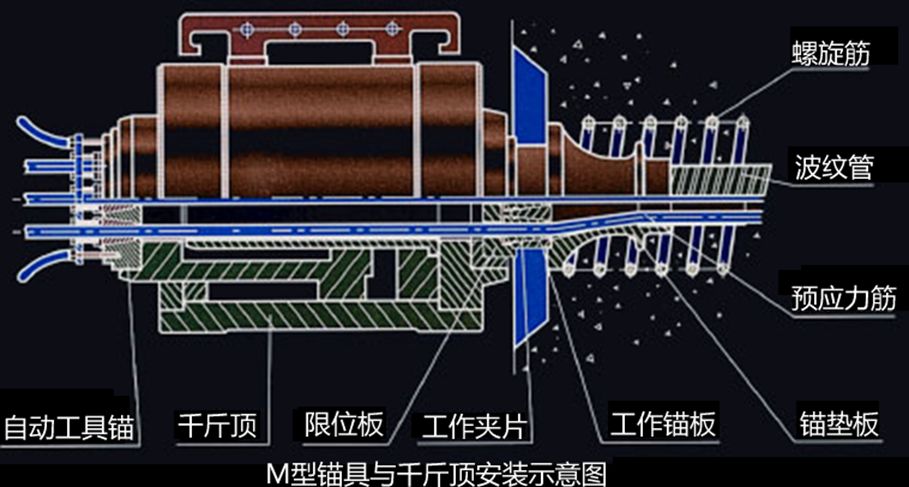

The tensioning pedestal shall have sufficient strength and stiffness, and its anti overturning safety factor shall not be less than 1.5 and anti sliding safety factor shall not be less than 1.3

.

The hardness shall be within the range required by product design

.

The coarse aggregate shall be crushed stone, and its particle size shall be 5 ~ 25mm

.

When stored outdoors, it shall not be directly stacked on the ground

.

If one test piece fails to meet the requirements, double the number of anchors (clamps or connectors) shall be taken for retest

.

Portland cement and ordinary portland cement shall be preferred for prestressed concrete, slag Portland cement shall not be used, and pozzolanic Portland cement and fly ash Portland cement shall not be used

.

Acceptance shall be carried out in batches

.

If one part is still unqualified, the batch of products shall be inspected one by one, and the qualified products can be used

.

2

.

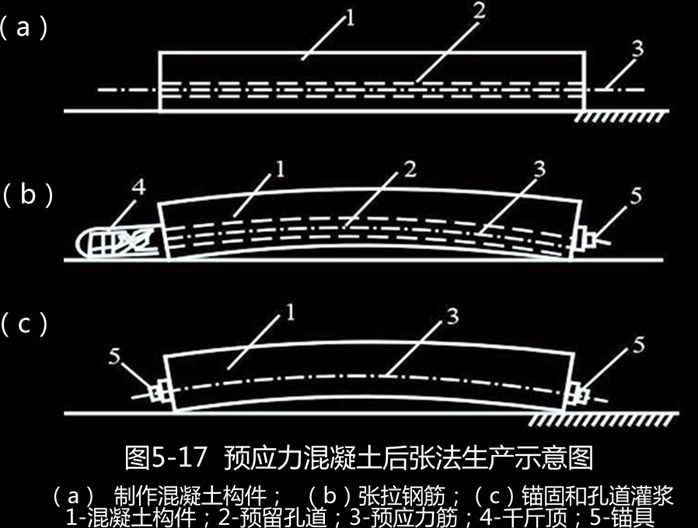

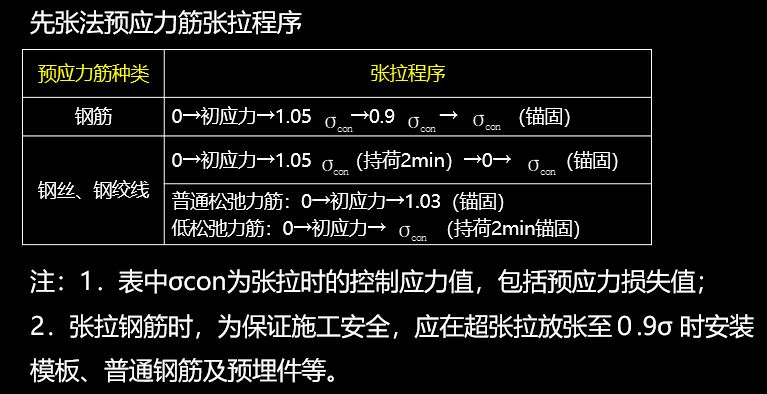

If you don’t understand it, supplement a) tensioning reinforcement; b) Placing concrete; c) Loosen or cut the prestressed reinforcement 1- anchorage; 2 – pedestal; 3 – prestressed reinforcement; 4 – table top; 5 – tensioning jack; 6 – formwork; 7 – prestressed concrete components (pre tensioning method) (schematic diagram of post tensioning method) (schematic diagram of post tensioning method) (schematic diagram of post tensioning method) I

.

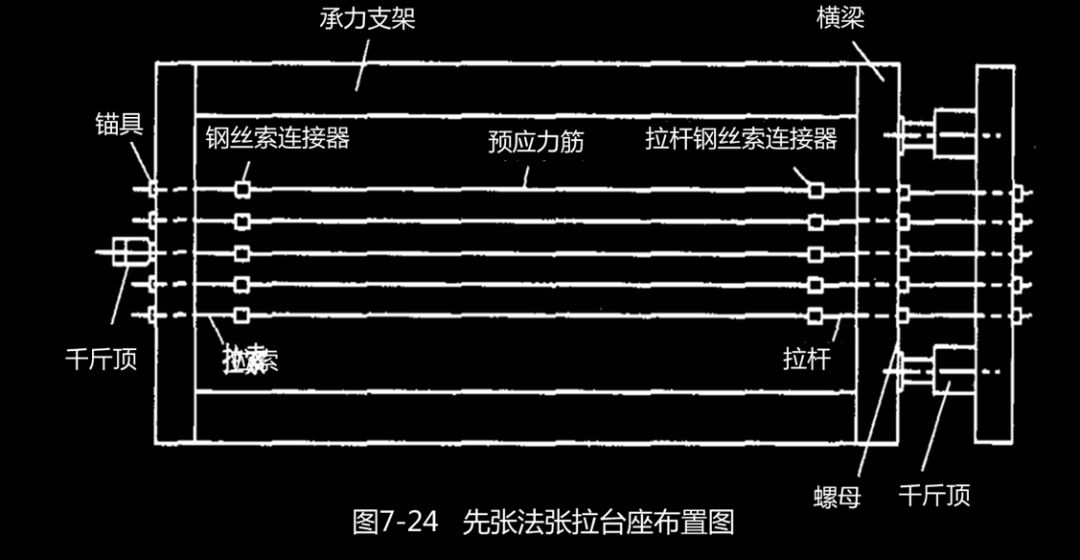

(II) pretensioning prestressed construction 1

.

The pipe poured in concrete shall have sufficient strength and stiffness, no slurry leakage is allowed, and the bonding force can be transmitted as required

.

Admixtures containing chloride, air entraining agent or air entraining water reducing agent shall not be used in concrete

.

The tensioning beam shall have sufficient rigidity, and the maximum deflection after stress shall not be greater than 2mm

.

The difference between the actual elongation value and the theoretical elongation value shall meet the design requirements; If there is no provision in the design, the difference between the actual elongation value and the theoretical elongation value shall be controlled within 6%

.

3

.

(5) attention shall be paid during the installation of prestressed reinforcement: the prestressed reinforcement shall be cut by grinding wheel saw or cutting machine, and arc cutting shall not be used( 2) Pipes and ducts 1

.

If one item is still unqualified, the batch of steel strand is unqualified

.

If one of the inspection results is unqualified, the unqualified coil shall be scrapped, and double number of samples shall be taken from the batch of untested steel strands for re inspection of the unqualified item

.

2) The weight of each batch of steel strand inspection shall not be greater than 60t; Take 3 coils of steel strand from each batch, and cut a sample from the normal part of the end of the selected steel strand for surface quality, diameter deviation and mechanical property test

.

In post tensioned bonded prestressed concrete structures, the ducts of prestressed tendons are generally composed of rigid or semi-rigid pipes poured in concrete

.

2

.

Take samples at both ends of each coil of steel wires for tensile strength, bending and elongation tests

.

The anchorage shall meet the requirements of graded tensioning, supplementary tensioning and relaxation of prestress( 2) Acceptance regulations 1

.

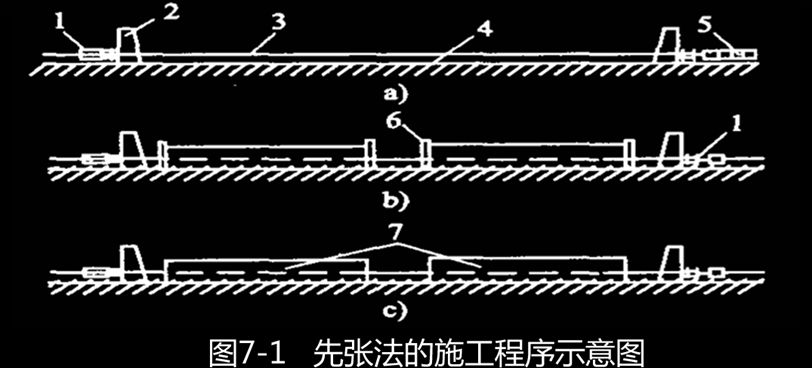

According to different anchorage methods, post tensioned prestressed anchorage and connector can be divided into clip type (single hole and multi hole clip Anchorage), supporting type (heading anchorage and nut Anchorage), cone plug type (steel cone Anchorage) and grip type (extrusion anchorage, embossed anchorage, etc.)

.

If one of the test results is unqualified, the steel wire shall be scrapped, and double number of samples shall be taken from the steel wire discs that have not been tested in the same batch for re inspection of the unqualified item

.

4

.

Static load anchorage performance test: for important projects such as major bridges and super major bridges, when the quality certificate is incomplete, incorrect or doubtful, 6 sets of anchors (clips or connectors) shall be selected from the same batch passing the appearance and hardness inspection to form 3 prestressed reinforcement anchor assemblies, The static load anchorage performance test shall be carried out by a professional quality inspection institution authorized by the national or provincial quality and technical supervision department

.

The stress center of anchor plate shall be consistent with the resultant force center of prestressed reinforcement.

.

3) The weight of each batch of finished rolled rebar shall not be greater than 60t; The surface quality shall be visually inspected one by one

.

When one set is unqualified, double the number of anchors shall be taken for re inspection

.

During batch division, products produced under the same material and production process conditions can be listed as the same batch

.

3

.

For the mobilization acceptance of anchors (clips or connectors) used for small and medium-sized bridges, the static load anchorage performance can be provided with the test report by the anchor manufacturer

.

The surface of all samples shall be free of cracks, and the dimensional deviation shall not exceed the allowable dimensional deviation specified in the product standard and design drawings

.

Hardness test shall be conducted for parts with hardness requirements

2、 Basic requirements for anchorage and connector (I) 1

.

If the inspection is unqualified, all the batch of steel wire shall be inspected

.

The standard construction method of prestressed tensioning shall be taught by pictures and texts on site

.

The storage time shall not exceed 6 months

.

2

.

Spot check 5% of the qualified steel wires and no less than 3 coils

.

If the area is less than this area, test shall be conducted to verify whether it can carry out normal grouting operation

.

During prestress tensioning, it shall be adjusted to the initial stress first( σ 0), the initial stress should be the tension control stress( σ 10% ~ 15% of con), and the elongation value shall be measured from the initial stress

.

Each acceptance batch of connectors shall not exceed 500 sets( 1) For appearance inspection, 10% and no less than 10 sets of anchors from each batch shall be selected for appearance quality and overall dimension inspection

.

Otherwise, the tensioning shall be suspended until the cause is found out and measures are taken

.

After confirmation, the appearance inspection, hardness inspection and static load anchorage performance test shall be carried out

.

At least 5 pieces shall be selected for each set of clip of porous sheet added anchor, and 3 points shall be tested for each part

.

If there is still one unqualified item, the batch of steel wire is unqualified

.

If each batch is less than 3 discs, all shall be inspected

.

3、 Prestressed concrete preparation and pouring (I) preparation 1

.

During the mobilization acceptance of anchors, fixtures and connectors, the anchorage performance category, model, specification and quantity shall be checked according to the factory certificate and quality certificate

.

3

.

If one of the test results is unqualified, double the number of samples to repeat the test

.

The amount of cement in concrete should not be greater than 550Kg / m3

.

4

.

Other requirements for pipeline (1) in some special parts of the bridge, if there are no design requirements, smooth steel pipe or high-density polyethylene pipe meeting the requirements can be used, and the pipe wall thickness shall not be less than 2mm( 2) The internal cross-sectional area of the pipeline shall be at least 2.0 ~ 2.5 times of the net cross-sectional area of the prestressed reinforcement

.

If one part is unqualified, double the number of parts shall be taken for re inspection

.

prestressed reinforcement and pipeline (I) prestressed reinforcement (1) each batch of steel wire, steel strand and reinforcement shall be composed of products of the same brand, specification and production process( 2) When the prestressed tendons enter the site, their quality certificates, packaging, marks and specifications shall be inspected, and shall meet the following requirements: 1) the weight of each batch of steel wire inspection shall not be greater than 60t; Spot check 5% of each batch of steel wire and no less than 5 coils for shape, size and surface quality inspection

.

When the prestressed reinforcement is tensioned by the stress control method, it shall be checked by the elongation value

.

If one item is still unqualified, the batch of reinforcement is unqualified( 4) The warehouse shall be dry, moisture-proof, well ventilated and free of corrosive gas and medium

.

If one test piece still fails to meet the requirements, this batch of products shall be regarded as unqualified products

.

It must be padded, covered, corrosion-proof and rain proof

.

If one set still fails to meet the requirements, it shall be inspected one by one, and the qualified ones can be used( 2) For hardness test, 5% and no less than 5 sets of anchors shall be selected from each batch for hardness test

.

The area ratio of pipes with extra long tendons shall also be determined by test

.

No more than 1000 sets of anchors and clips shall be regarded as an acceptance batch

.

4、 Basic provisions for prestressed tensioning construction (I) 1

.

Anchors (or connectors) that can only be applied to low-strength prestressed tendons shall not be used for high-strength prestressed tendons

.