Compared with traditional manual construction, robot construction has significant advantages in safety, quality and efficiency

.

Construction Technology | Heavy! The Emergency Management Department officially issued the full text of the work safety law, which came into force on September 1! Source: Country Garden

.

The floor grinding robot with a height of about 1.7m immediately starts its independent operation

.

Recent hot information recommendations, click to view: 1

.

//Wechat public account setting prompt/// The official account is official

.

All positions of the whole machine are equipped with synchronous jacking function, synchronous control system and automatic closed-loop control height difference

.

It has a dust collection system to reduce dust hazards ▲ the operation of exterior wall putty polishing robot, and the spraying of exterior wall primer is attached to the ring rail car

.

Not long ago, country garden also released a national recruitment plan for new industrial workers for collaborative construction by construction robots, so as to cultivate and reserve a team of professional and technical talents for the comprehensive promotion of robot building in the future

.

If the original copyright owner disagrees

.

Look at the intelligent follow-up distributor! The pink “tall” intelligent follow-up distributor stands on the construction surface

.

▲ measurement robot in floor cleaning robot ▲ measurement robot in work indoor spraying robot floor tile paving robot wall tile paving robot intelligent spray maintenance system has the characteristics of remote control and independent coverage, effectively adsorbs dust and particles in the air to complete concrete maintenance, and can cool down outdoor workers and improve the construction environment Protect the health of construction workers, respond to the concept of environmental protection ▲ intelligent spray maintenance system, intelligent detection system, multi network integration and strong coverage, more convenient information acquisition, high safety and reliability, faster emergency disposal, digital large screen integration, simple real-time broadcasting deployment, and more intuitive safety and quality supervision ▲ compared with the traditional construction method, The platform can easily realize the automatic operation of various processes such as high-altitude construction protection, construction layer leveling, troweling, concrete maintenance and so on

.

Construction Technology | Ministry of housing and urban rural development: the 2021 professional evaluation (certification) conclusions of architecture and civil engineering in Colleges and universities are published! 2

.

It not only grinds fast, the efficiency is nearly three times higher than that of manual work, but also is very clean, leaving the construction site free from dust! ▲ during the operation of floor grinding robot, the floor cleaning robot is at the robot special channel on the first floor

.

At present, in the industry, It takes 2-3 hours for most building platforms to lift a structural floor

.

Industrial workers operate and detect all links of construction with the help of intelligent technology software, so as to completely innovate the production mode of the construction industry

.

The sanding paper is self-adhesive, which can be quickly replaced and adjusted

.

The external wall putty polishing robot automatically adjusts to adapt to the changes of the wall, and it is smoother after adjustment and polishing, The overall efficiency is improved by 3 times

.

When multiple buildings are constructed at the same time, it can also realize the turnover in the horizontal direction, which is convenient, fast and easy to operate

.

The standard floors of all buildings in this project can be poured from the concrete pumped out by it, and the cumulative operation volume has exceeded 22000 cubic meters! ▲ during the operation of intelligent follow-up distributor, the concrete robot held a handover ceremony in Fengtong garden project of country garden in Shunde

.

▲ traditional manual construction vs intelligent building robot construction Yang Guoqiang requires that each region should select a person who understands architecture, management, science and technology, economy, ability, fear of hardship and has the spirit of study as the regional leader to lead the pilot project of robot building“ Robot building is the core competitiveness of the company

.

Construction Technology | sudden! 8 dead and 2 injured! Collapse of a building under construction in Yong’an, Fujian 3

.

The floor cleaning robot is driving slowly, automatically cleaning small stones and dust on the construction site, and the ground where it passes becomes as clean as new

.

All exterior wall actuators can be attached to the general ring rail car and mechanical arm

.

If you don’t want to miss the highlight of this official account, please put the public number of construction technology as the star sign and click “collect”, “look at” and “Zan” at the end of the text, so that each new article will appear in the subscription list at the first time

.

Let’s take a look at the construction robots and auxiliary intelligent equipment that have been put into use

.

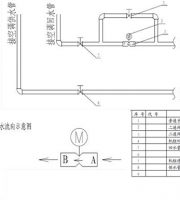

At present, it takes only about 1 hour for the whole building platform to lift a floor, which is more than twice as long ▲ the synchronous lifting function of the self lifting building platform is used as the auxiliary lifting tool

.

The copyright belongs to the original author and original source

The safety and efficiency is about twice that of manual spraying, which effectively reduces the potential health hazards to construction workers, and is safe and reliable, Flexible and efficient ▲ the floor grinding robot for exterior wall primer spraying is on the operation site of the underground garage

.

The external wall putty coating robot can automatically fit the changes of the wall during the construction process, and automatically carry out the second example

.

On July 9, 2021, Yang Guoqiang, founder and chairman of the board of directors of country garden, stressed at the group management meeting that “we should go all out to do a good job in the pilot project of robot house building

.

The man-machine cooperative operation construction system with construction robot as the core was officially put into use on the front line, opening the practical mode! ▲ the concrete robot is carrying out leveling work ▲ the concrete robot is carrying out troweling work

.

NOCITCE changed the push rule because of WeChat official account

.

At present, country garden is actively promoting the construction robot pilot project

.

The adjustment and coating construction quality is high, and the overall efficiency is improved by 3 times ▲ the external wall putty coating robot works

.

▲ in the operation of exterior wall spraying robot, a new generation of intelligent residential building automation construction platform “self elevating building platform” ▲ self elevating building platform drawing

.

Under Yang Guoqiang’s plan, in the near future, the intelligent construction factory will produce robot “workers” on demand

.

The concrete leveling and troweling robot has the advantages of small volume, light weight, flexible steering, high precision, small error (controlled at 0-5mm), dense vibration, remarkable slurry lifting effect, high degree of automation, and greatly reduce the labor intensity of workers ▲ concrete leveling In the plastering robot operation, the external wall spraying robot can avoid the high falling risk of traditional spraying through automatic spraying operation, and the maximum spraying efficiency can reach 300 ㎡ per hour

.

Star setting: enter the official account home page, click on the top right corner, click “set star”, and yellow star will appear next to the official account name (Android and iOS user operation is the same)

.

” Mo Bin said that after selecting excellent talents, the company will regularly carry out special research and training on robots

.

” Yang Guoqiang proposed at the meeting that robot building will be fully realized next year

.

Workers in the construction industry issue construction tasks with one click on the tablet computer

.

Through scientific planning, robots will enter the construction site in an orderly manner to complete construction

.

As of June this year, bozhilin robot company has put 18 construction robots into commercial application, covering more than 65 projects in 14 provinces, with a cumulative application and construction of more than one million square meters

.

During operation, only the actuator head needs to be replaced

.

8 strong suction cups are used to jointly carry a single suction cup, which can carry 100kg, effectively improving the manual operation efficiency, Safe and efficient ▲ auxiliary lifting tool operation external wall staggering grinding robot is attached to the external wall ring rail, with modular design, small volume, light weight, accuracy error of ± 3mm, and rapid assembly and disassembly of staggering grinding component and mechanical arm with maximum cutting depth of 10mm, The cutting and grinding process has the function of dust absorption, high standardized construction efficiency and environmental protection ▲ the external wall staggered grinding robot works, and the external wall screw hole plugging robot works with the ring rail car for accurate positioning, so that the overall automatic plugging efficiency is increased by more than 3 times, covering more than 90% of the external wall, with dense plugging and reliable anti-seepage, The finished product has good visual effect ▲ the external wall screw hole plugging robot works

.

From next year, we will all build houses with robots

.