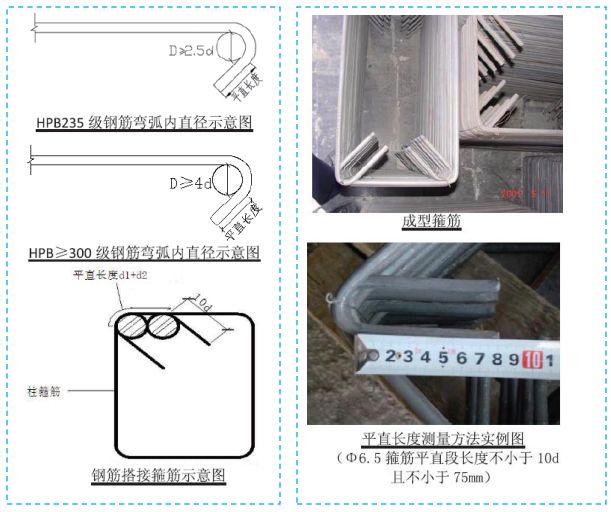

The bending angle at the end of stirrup shall not be less than 135 °, and the length of straight section shall not be less than 5D for non seismic requirements, 10d and 75mm for seismic requirements

.

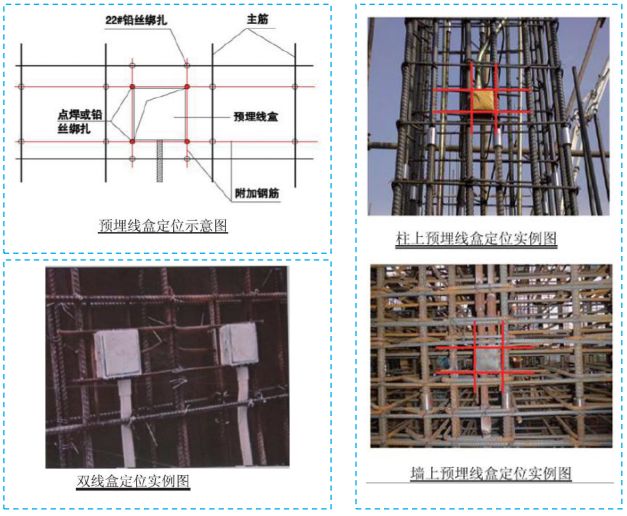

For the wire box embedded in the wall, in order to achieve the effect of one-time forming, during the wall reinforcement construction, the wire box installation process must be carried out after the column wall reinforcement is bound and before the formwork is closed

.

The calender shall be used for a large area and the artificial iron trowel shall be used for details to close the surface cracks

.

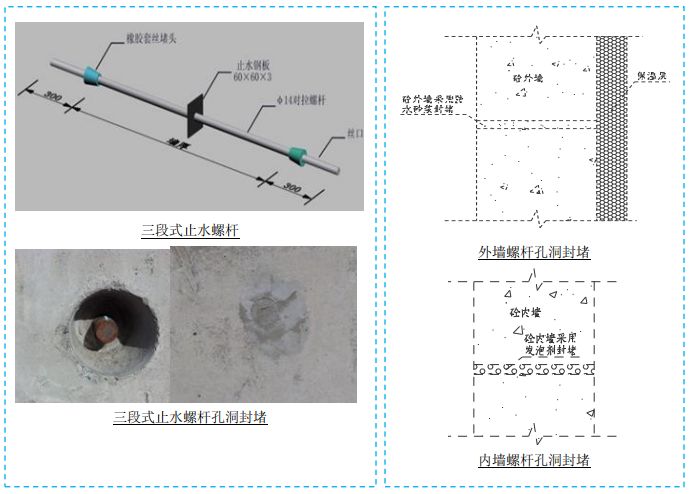

The screw holes of ordinary external wall are blocked with 1:2 dry hard cement mortar (add waterproof agent and expansion agent), and the bolt holes of internal wall are blocked with foaming agent

.

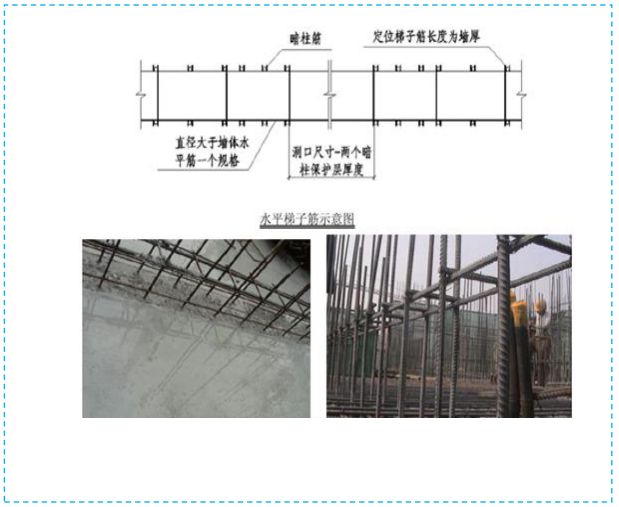

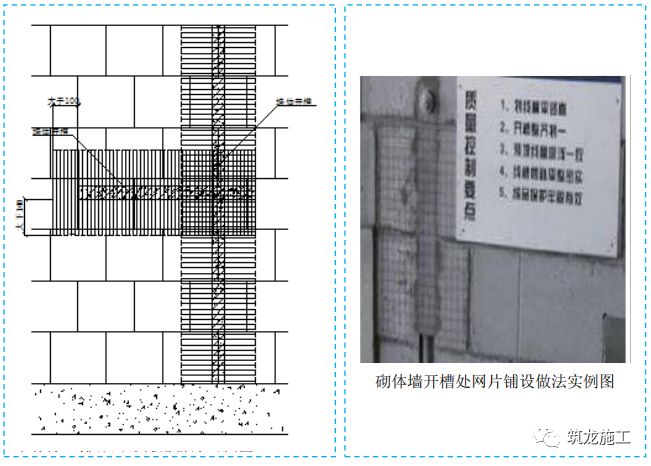

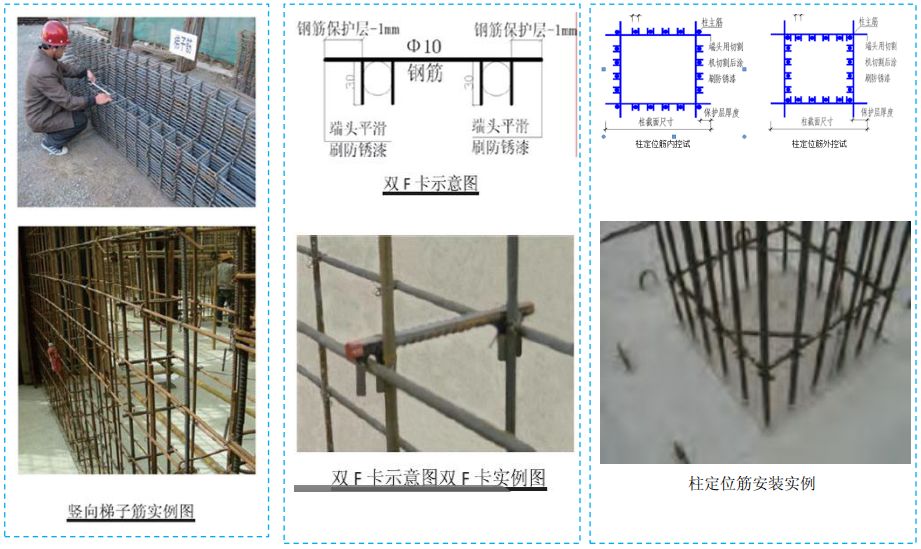

When the diameter of the wall reinforcement is greater than 16mm, the vertical positioning reinforcement can be cancelled and the double f card can be used for positioning

.

Source: China Construction two bureau, Baidu library copyright to original author all directories, reinforcement works two, template works three, concrete works four, masonry works five, special projects 1 steel works 1.1 stirrup processing

.

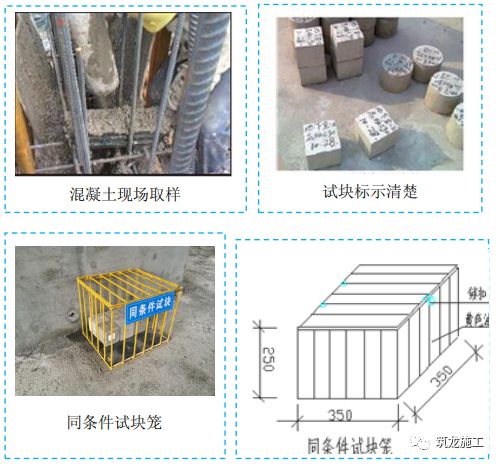

The standard curing concrete test block shall be sampled at the outlet of the tank

.

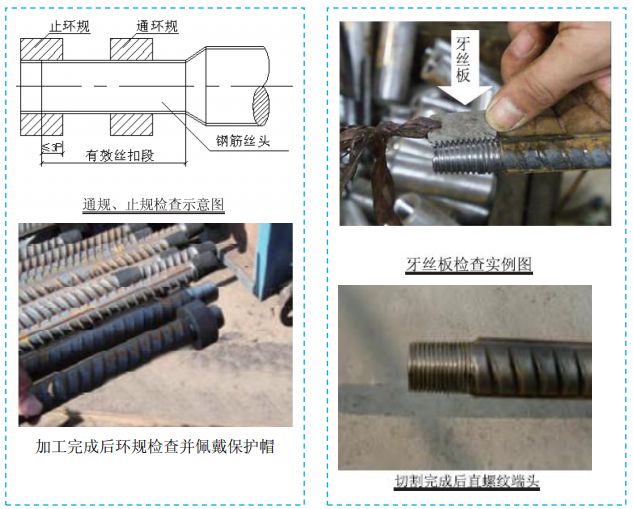

The effective Screwing Length of the steel wire head thread is detected with a special wire head clamp, and the allowable deviation is ≤ 1p

.

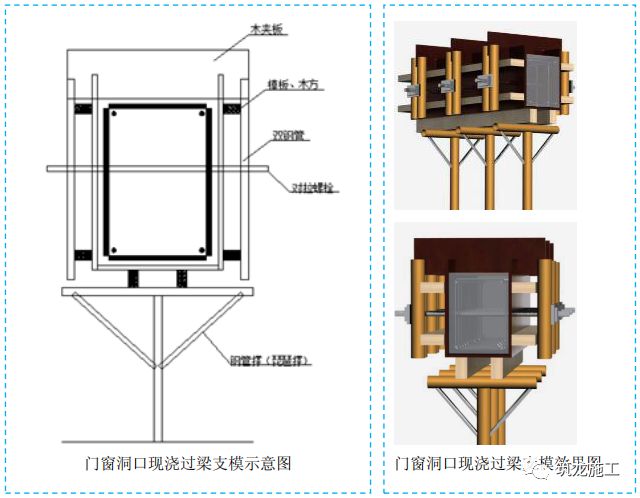

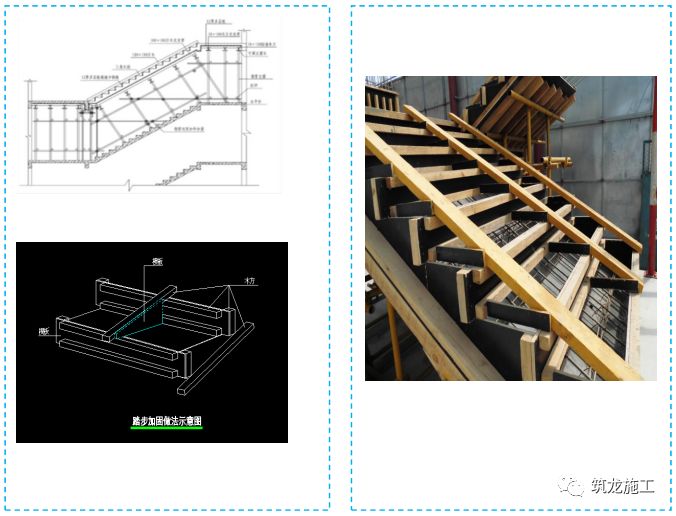

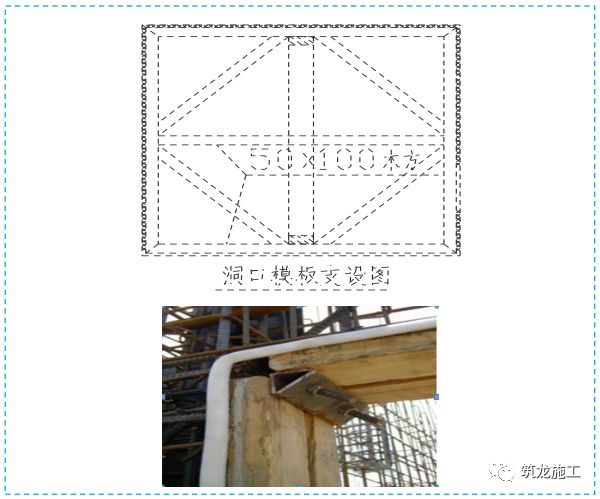

When pouring concrete, it is poured from both sides of the portal at the same time to avoid formwork deviation

.

Waterproof mortar shall be used to block the water stop screw holes in the basement, and the blocked parts of the inner wall must be painted with antirust paint before scraping white

.

During pump pouring, effective control measures shall be taken to control the floor height, such as real-time control with infrared laser level or control with stereotyped measurement mold

.

4

.

3

.

Under the same conditions, the concrete test block shall be placed at an appropriate position close to the corresponding structural members or structural parts (in the locked reinforcement cage), and the same curing method shall be adopted

.

Basic requirements: 1

.

2

.

The concrete test block shall be marked with: position, test piece number, molding date and strength grade

.

The standard curing conditions shall be 20 ± 2 ℃ and the humidity shall be more than 95%

.

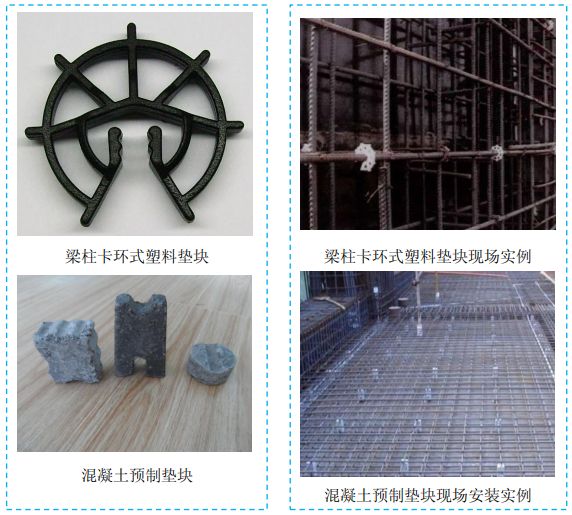

1.5 basic requirements for precast cushion blocks: 1

.

2

.

1.4 basic requirements for wire box embedding Construction: 1

.

The laboratory is managed by full-time experimenters

.

Under the same conditions, the concrete test block shall be sampled at the working face

.

2

.

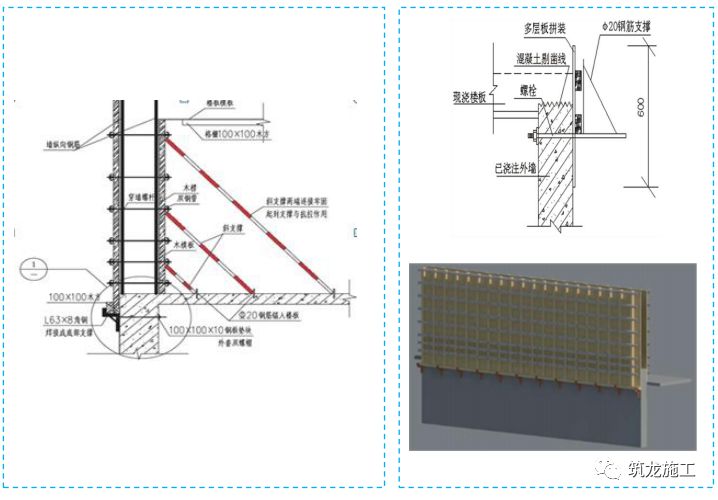

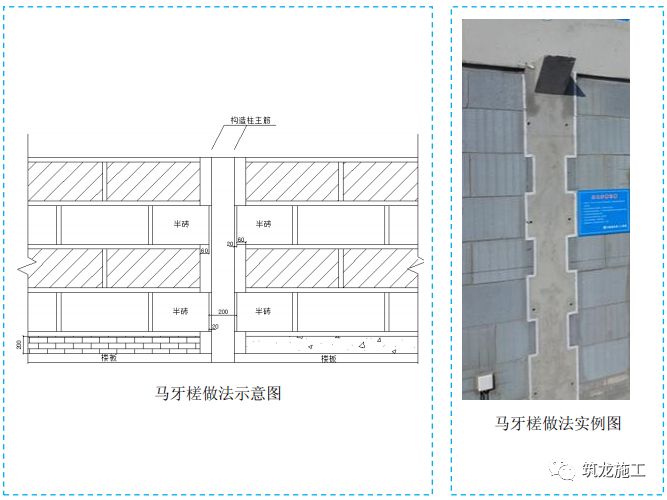

When light aggregate concrete small hollow blocks and autoclaved aerated concrete blocks are used to build walls in kitchens, toilets and bathrooms, the wall bottom should be cast-in-situ concrete sill, the height should be 150mm, and the width should be reduced by 1-2cm according to the design width of the wall

.

Before the final setting of concrete, the concrete surface shall be troweled and calendered in time

.

The number of samples and test pieces retained shall comply with relevant regulations and meet the actual needs; At least two groups shall be added during winter construction

.

3

.

2

.

During the pouring of the guide wall, the guide wall shall be vibrated and compacted with a small vibrator, and the upper plane of the guide wall shall be leveled.

.

When finishing the reserved hole, post cast strip and sinking plate, it must be troweled manually

.

The inspection of the pitch diameter of the thread of the reinforcement thread head shall meet the requirements that the through-loop gauge can be screwed into the whole effective thread length smoothly, while the screw head depth of the stop loop gauge is ≤ 3P (P is the pitch)

.

The vertical ladder reinforcement of the wall shall be welded and processed with reinforcement one specification higher than the vertical reinforcement of the wall, and can replace the vertical reinforcement of the wall

.

2

.

3

.

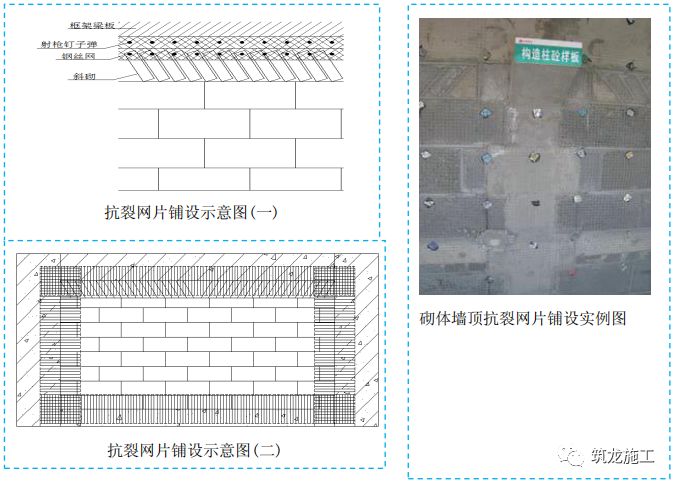

2 formwork works 2.1 wheel buckle scaffold Basic requirements: 1

.

2

.

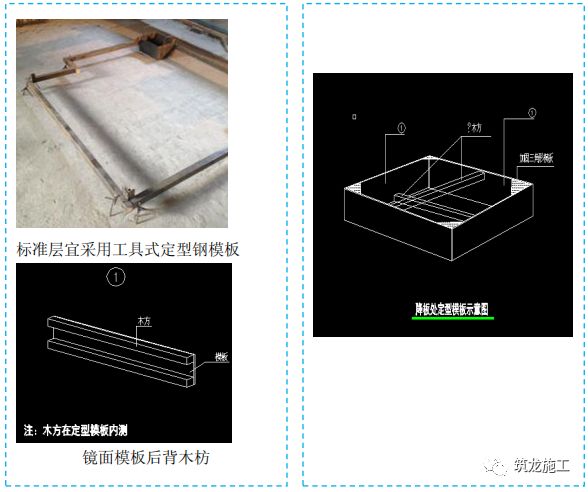

Double lines (frame column position line and 100mm control line) shall be snapped according to the positioning axis and section size of the frame column

.

Ordinary steel bar cutter is strictly prohibited

.

3

.

The new three-stage water stop screw is mandatory for the outer wall of the basement and the civil air defense wall with functional requirements

.

The internal and external corners of the formwork are fixed with angle steel and wood formwork

.

The protective layer of reinforcement at the side of beam and wall can be controlled by double f card and cushion block

2.2 basic requirements for pull screws: 1

.

3

.

The column positioning hoop is set 500mm above the floor elevation, and the center spacing of the positioning clamp reinforcement is the reinforcement diameter plus 3mm

.

4

.

Double lines (shear wall side line and 100mm control line) shall be snapped for the positioning axis and section size of the shear wall

.

2

.

See details of standard curing room for concrete test blocks of Northeast Branch of China Construction Second Engineering Bureau for laboratory area, layout and specific practices

.

3

.

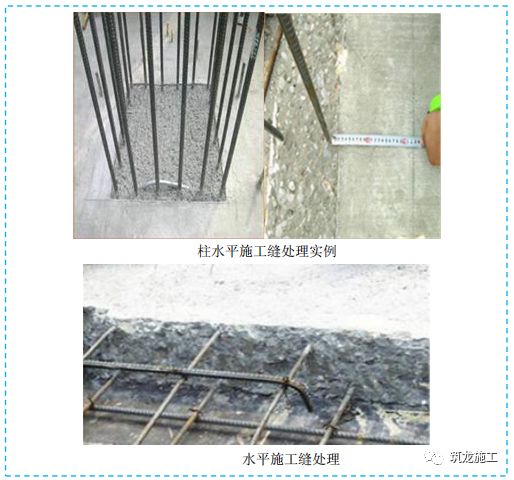

Treatment of construction joint at the bottom of wall column: after the concrete strength reaches 1.2MPa, immediately remove the surface laitance and weak layer, conduct roughening treatment, and make the removal concave down by 10mm to ensure the quality of concrete joint

.

The frame can effectively ensure the spacing of upright rods, the setting of sweeping rods, the step distance and the height of the top free end

.

4 masonry works 4.1 toilet waterproof sill Basic requirements: 1

.

2

.

Fully wet without ponding

.

Simple and reasonable structure, convenient use, safety, simple storage and maintenance

.

1.2 basic requirements for reinforcement straight thread processing: 1

.

Both ends of the clip shall be cut with a toothless saw, and the end shall be painted with 15mm antirust paint

.

2.5 wall positioning line Basic requirements: 1

.

4

.

Firstly, fix the wire box in place, and then paste the film to make the outer surface of the wire box flush with the wall or slightly concave by about 2mm than the wall

.

Under the same conditions, the test block cage is welded with ¢ 6.5 or ¢ 8 reinforcement, which is required to be locked and closed

.

Stirrup forming size: remove twice the thickness of reinforcement cover from the beam (column) section size

.

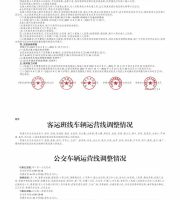

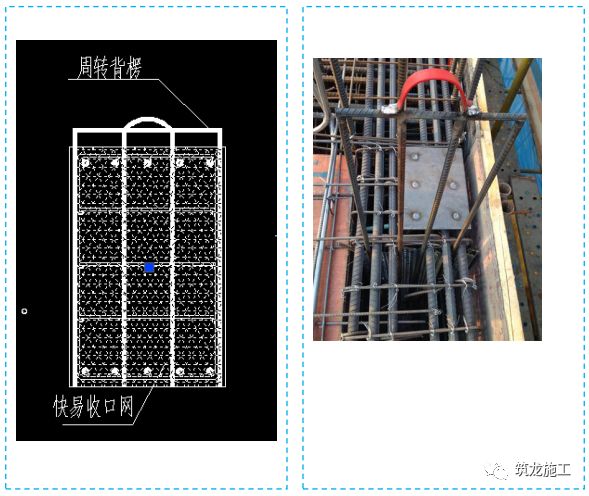

2.3 basic requirements for portal formwork erection: the portal formwork is processed into shaped formwork according to the dimensions of the drawing

.

3

.

5

.

The horizontal ladder reinforcement of the wall is fixed at 150-200mm at the top of the wall to control the spacing and position of vertical reinforcement

.

When erecting the guide wall formwork, in order to prevent the upper formwork from running, the shaped wood splint or the clamp made of wood square and screw shall be used to fix it firmly, and step-by-step reinforcement is not allowed

.

2.4 basic requirements for internal corner control: the length of double row steel pipes is staggered, the cross fastener of two-way steel pipes is locked, two wooden squares are placed horizontally at the internal corner, the cross staggered steel pipes reinforce the wooden squares at the internal corner, the staggered edges are in place, the gap is tightened with wooden wedges, and the first through wall screw is 200mm away from the wall

.

The wet temperature shall be recorded at least twice a day

.

The size is: length x width x height = 35cmx35cmx25cm, painted with yellow paint and marked on the signboard

.

The temperature in the concrete test block manufacturing room is 15 ~ 25 ℃

.

If the wall formwork adopts steel formwork, the formwork control line can be 200mm

.

During construction in winter, the construction joint shall not be washed by water, but shall be cleaned by air pump

.

2

.

Basic requirements: 1

.

Treatment of slab construction joints: loose stones and loose concrete shall be removed, and the surface shall be fully cleaned

.

1.3 wall positioning reinforcement and column positioning hoop Basic requirements: 1

.

After the straight thread threading is completed, a protective cap must be installed for protection

.

One reinforcement shall be set every 1.8m

.

6

.

3.4 basic requirements for the production of concrete test blocks: 1

.

Direct sampling from the tank truck is not allowed

.

2

.

Before chiseling, the chiseling line shall be snapped to ensure that the chiseling edge line is smooth and straight

.

3.3 basic requirements for standard curing room of concrete test block: 1

.

2

.

If the column formwork adopts steel formwork, the formwork control line can be 200mm3 concrete engineering 3.1 concrete pouring elevation and finish control Basic requirements: 1

.

3.2 basic requirements for construction joint treatment: 1

.

Use grinding wheel cutting machine or semi-circular knife edge reinforcement cutting machine to cut, so as to ensure that the end of reinforcement is straight without horseshoe or eccentric head

.

3

.

Two additional rebars in longitudinal and transverse directions shall be selected for fixation, and the additional rebars can be fixed by spot welding

.

Double row two-way and diamond support is adopted inside

.

Concrete precast cushion blocks are recommended for beam bottom and slab bottom cushion blocks, and marble cushion blocks are not allowed

.

At the same time, it is more convenient to remove the wall formwork and will not prematurely remove other rods and affect the overall stability of the frame

.

2

.

The production of concrete test blocks is the responsibility of full-time personnel

.

Exhaust holes are set at the lower part of the portal formwork, and sponge strips are pasted on the side to prevent slurry leakage

.

The laboratory shall be equipped with constant humidity incubator (air conditioner and humidifier), thermometer, hygrometer, vibrating platform, slump cylinder, platform scale, test block mold, water tank, air pump, test block frame, shovel, recording tool and cleaning tool

.

2

.