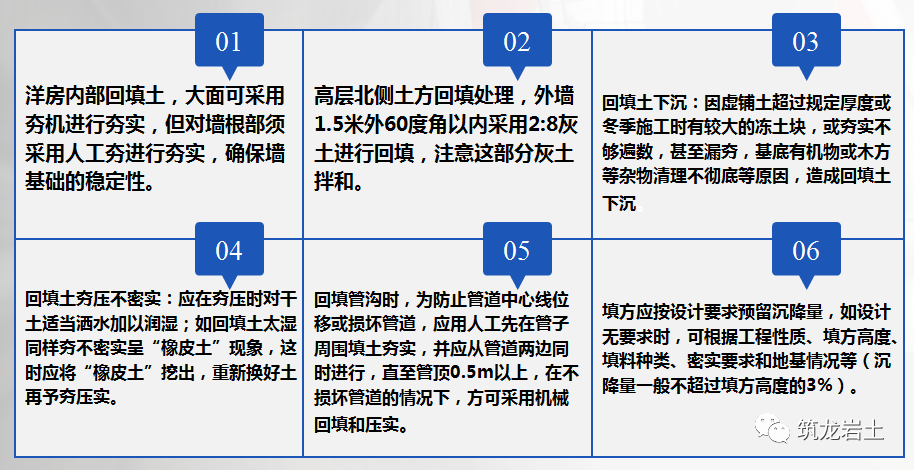

⑤ For the filling below the ground of buildings (structures) under construction, if the filling thickness is less than 0.5m, the garbage on the foundation base shall be removed

.

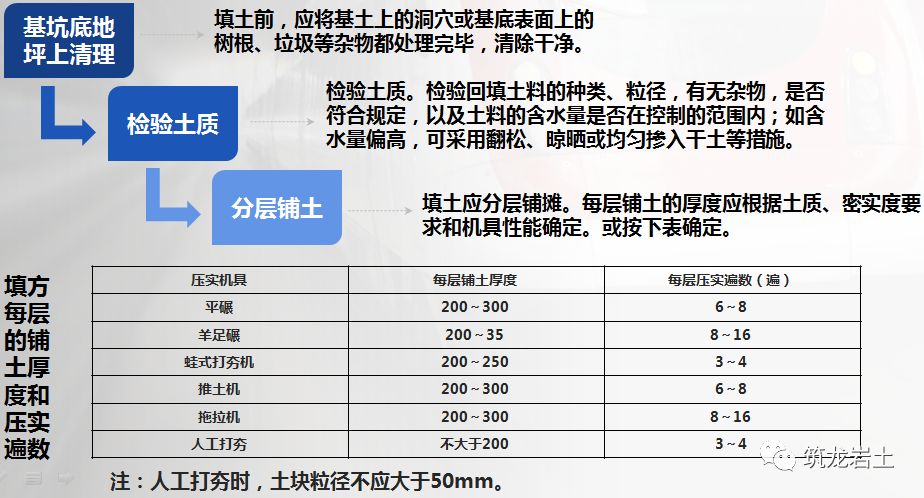

③ Before large-scale earthwork backfilling, the water content of the filling, the thickness of each layer of filling and the number of compaction times shall be reasonably determined according to the engineering characteristics, the type of filling, the design compaction coefficient, the construction conditions and the compaction process

.

The quantities of excavation and soil transportation in the quota are calculated according to the natural dense – natural square

.

Horizontal piles shall be driven on the edge of foundation pit (groove) or ditch slope according to the required spacing, and there shall be horizontal marks on the wall of indoor and apron

3

.

A material: high quality filler includes hard block stone, Boulder soil, pebble soil, gravel soil, round gravel soil, breccia soil, gravel sand, coarse sand and medium sand with good grading and fine-grained soil content less than 15%

.

According to the manufacturing method, it is divided into two types: woven geotextile and non-woven geotextile

.

The category of soil is not detailed, because the quota is very comprehensive and the details are ignored

.

If there are differences, there may be individual differences between civil engineering and municipal administration

.

④ for the backfilling of indoor platform and pipe trench, the installation of water supply and sewers (qualified by water test) or the masonry of partition wall shall be completed, The water and organic sundries in the filling area shall be removed before construction

.

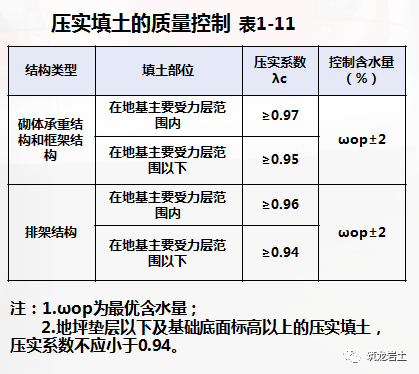

Compacted soil refers to the soil compacted by rolling in layers according to the specification requirements

.

When the imaginary square becomes the real square, it needs to be multiplied by the coefficient( 2)

.

Such as: outdoor pipeline damage, landscape hard pavement subsidence, ground subsidence and other quality hidden dangers

.

2

.

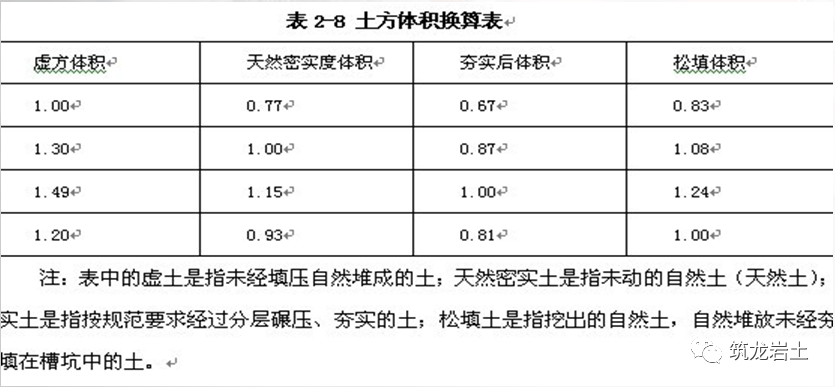

5、 Concept: (1) virtual square refers to the natural dense volume, while real square refers to the volume after manual treatment and compaction

.

⑥ Before filling, the horizontal elevation shall be measured

.

At this time, volume conversion should be considered

.

However, attention should be paid to such situations

.

So that there is no loss and mixing between two or more materials, maintain the overall structure and function of materials, and strengthen the bearing capacity of geotextile products of structures.

.

Transporting 1 cubic meter of virtual soil is only equivalent to 0.77 cubic meters of daily dense soil

.

How to convert the actual and imaginary quantities of earthwork? The virtual soil in the quota refers to the soil naturally piled without filling and pressing; Natural dense soil refers to undisturbed natural soil; Loose fill refers to the excavated natural soil, which is naturally stacked in the pit without tamping

.

The quota should be subdivided, but there is no subdivision

.

Function of geotextile: (1) isolation: polyester staple fiber needle punched geotextile is used to isolate building materials (such as soil and sand, soil and concrete) with different physical properties (particle size, distribution, consistency and density, etc.)

.

When using vibratory roller, the maximum particle size shall not exceed 2 / 3 or 3 / 4 of the paving thickness of each layer, and the moisture content shall meet the regulations

.

⑤ Broken turf and soil with organic matter content greater than 5% can only be used for filling without compaction requirements

.

However, attention should be paid to such quota, such as manual or mechanical transportation of loose soil

.

② The foundation, underground structures, underground waterproof layer and protective layer have been inspected and concealed acceptance procedures have been completed, and their structures have reached the specified strength

.

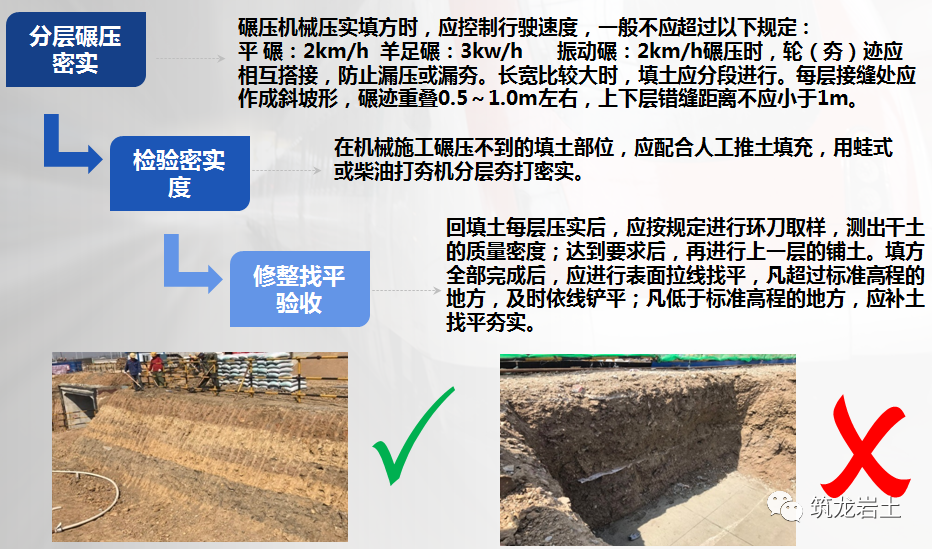

② Rolling machines include: flat roller, sheep foot roller, vibrating roller, etc

.

Material preparation: ① The site foundation pit and foundation trench shall be preferred for earthwork excavation

.

Precautions: generally, the calculation of earthwork excavation, filling and outward transportation quantities under quota does not need to consider the conversion coefficient, but is calculated according to natural dense soil

.

AB material 1

.

② Gravel soil, sandy soil (the use of fine sand and silty sand shall be approved by the design unit) and blasting ballast can be used as filler below the surface

.

During the secondary transfer of loose soil, attention should be paid to the classification of soil

.

The quota is prepared according to the national basic quota, and the earthwork problem should exist all over the country, which leads to the concept of making money in earthwork

.

④ Sludge and mucky soil can not be used for filling generally, but in soft soil areas, if the treated water content meets the compaction requirements, it can be used for secondary parts in filling

.

B material: good aggregate includes soft block stone (the cement is siliceous or calcareous), poorly graded boulder soil, pebble soil, gravelly soil, round gravel soil, breccia soil, gravelly sand, coarse sand, medium sand, Boulder soil, pebble soil, gravelly soil, round gravel soil, breccia soil and fine sand, clay sand, sand silt and sand clay with a content of 15% ~ 30%

.

Concept of geotextile: geotextile is a new building material, and its raw materials are synthetic fibers of high molecular polymers such as polyester, polypropylene, acrylic and nylon

.

2、 Construction preparation 1

.

Operating conditions: ① The filling base has been completed or treated according to the design requirements

.

Process flow: cleaning on the foundation pit floor → testing the soil quality → paving in layers → rolling and compacting in layers → testing the compactness → trimming and leveling acceptance IV

.

Machine preparation: ① Earth moving machinery: forklift, dump truck, bulldozer and Tipper, etc

.

3、 Operation process 1

.

2

.

The classification of soil in the quota is not detailed, because the quota is very comprehensive, the details are ignored, and the geological exploration report is difficult to be combined with the soil classification in the quota

.

For example, volume conversion should be considered when manually or mechanically transporting the unfilled and naturally stacked virtual soil

.

2

.

The conversion coefficient of virtual soil, natural dense soil, compacted soil and loose fill is according to the 2008 bill of specifications: The relationship between them is shown in the table below: 3

.

We still follow the rules, The rules are calculated as they are

.

the solid volume is the volume after compaction, and the virtual volume is the volume of loose earthwork after excavation or before backfilling

.

Consolidation: zhulongyantu I

.

The quota is prepared according to the national basic quota

.

Before the explanation of relevant earthwork quota is issued, it can only be calculated according to the existing rules

.

③ The water content of cohesive soil shall be tested and can be used only after it reaches the design control range

.

⑥ Among the saline soil containing salt, only the medium and weak saline soil can be used generally, but the filler shall not contain salt crystals, salt blocks or roots of saline plants

.

General machines are: frog or diesel rammer, trolley, shovel (flat head or pointed tip)

.

Geotextile has many functions, such as filtration, reverse filtration, isolation, reinforcement, protection, sealing and so on

.

The second is to make money for the construction units

.

At this time, the quota should be subdivided, but there is no subdivision, which will cause the money for transporting 1 cubic meter of soil to pay for the work of actually transporting only 0.77 cubic meters of soil, For independent earthwork with large quantities, special attention shall be paid to the conversion of earthwork volume, otherwise the earthwork transportation project will become fertilizer difference

.

3

.

This problem should be understood from two levels

.

Backfill refers to the construction process of borrow and backfill within 5m after the completion of concealed works such as foundation and cushion

.

The earthwork problem should be consistent throughout the country

.

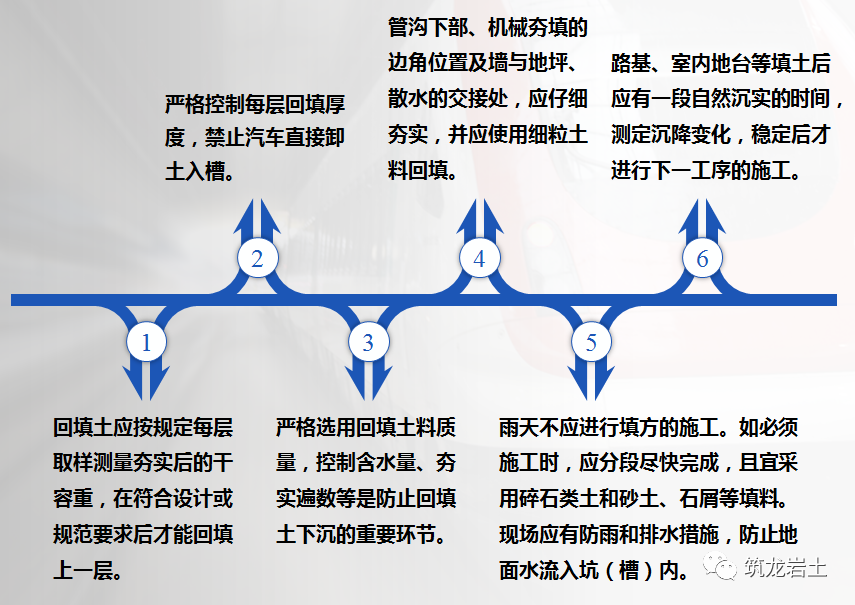

If the quality control of backfill is not in place, there will be many quality hidden dangers in the later stage

.

For borrow soil backfilling, the coefficient multiplied by 1.14 is specified in Yunnan 2003 quota, which reflects the conversion coefficient from borrow virtual volume to natural dense volume

.

When they settle accounts with the subcontractor, the less earthwork quantity paid after volume conversion becomes their profit

.

If one raw material needs to be mixed with another raw material, it is directly replaced by a material and B material, So it’s called AB material

.

General works are mainly published using non-woven fabrics

.

Generally, the excavation in Kunming defaults to class III soil, but the secondary transfer of loose soil should be considered as class I and class II ordinary soil, Because the earthwork is loose and uncompacted during secondary transportation, the difficulty of excavation and mechanical power consumption are different from those of natural dense soil transported with excavation

.

In fact, the current earthwork problem is generally calculated according to the natural compactness soil

.

What is ab material: ab material refers to that thing is used after mixing

.

definition of backfill: it refers to the return of the filled soil after the completion of the foundation and other works below the ground during the project construction

.

First, the earthwork volume is not converted when it is converted, As a result, more money is used to pay less quantities

.

6、 Geotextile 1

.