The formwork and scaffold that hinder the threading construction shall be cleaned, and the sundries shall be removed.

b.

When the threading line is blocked, two iron wires shall be stirred at both ends at the same time to hook and twist the ends of the two iron wires together, and then pull out the belt line.

The wire is completely protected by the protective pipe and is not easy to be damaged.

5.

In case of omission or damage, it shall be supplemented and replaced( 2) When the pipeline is long or there are many turns, blow an appropriate amount of talc powder into the pipe while threading( 3) When two people thread, they should cooperate and coordinate, one pulling and one sending( 4) Pay attention to the following problems when threading: A.

Installation process of insulated conductor in pipe 2.

The insulation layer at the front end of the conductor can be cut off, and then the wire core can be directly inserted into the coil of the strip line, folded back and compacted, and bound firmly to form a smooth conical transition part at the binding place( 2) When the number of conductors is large or the cross-section of the conductor is large, the insulation layer at the end of the conductor can be cut off, and then the wire cores can be arranged obliquely and staggered on the belt line, which can be wrapped and bound firmly with binding wires, so as to form a smooth conical transition part at the binding joint, which is convenient for threading.

Setting out and disconnection (1) setting out a.

single layer stripping method: generally, the exploitation pliers are used for single-layer wires less than 4mm2.

The angle tilt cuts the insulating layer.

Merge the two wires with each other.

On the left and right, push out the front end along the surface of the core, then peel the remaining insulating layer off the core, insert it into the back with a knife edge and cut it at an angle of 45 °( 2) Straight line connection of single core copper conductor A.

No joints, partial insulation damage and dead bends are allowed for insulated wires threaded into the pipe.

When using an electrician’s knife, it is not allowed to use the knife to cut the insulation layer around the wire.

b.

This wiring method is relatively safe and reliable and is generally used in various buildings.

before setting out, the specification, model and color of the conductor shall be confirmed according to the construction drawing.

During paying off, the conductor shall be placed on the paying off rack.

The piping and trunking of strong current shaft and weak current shaft in high-rise buildings have been installed.

Nylon binding tape shall be used during binding, and wire binding is not allowed( 2) Broken wire: when cutting the wire, the reserved length of the wire shall be considered according to the following four situations: a.

2.

Cooperate with the ceiling construction of civil engineering and complete the installation of piping or trunking.

The reserved length of the conductor in the distribution box shall be 1 / 2 of the perimeter of the distribution box.

Fold the branch line into 90 ° and close to the main line.

Cross the two wires, twist the two core wires for two turns with both hands at the same time, wind the two cores on the other core for 5 turns, and cut off the rest.

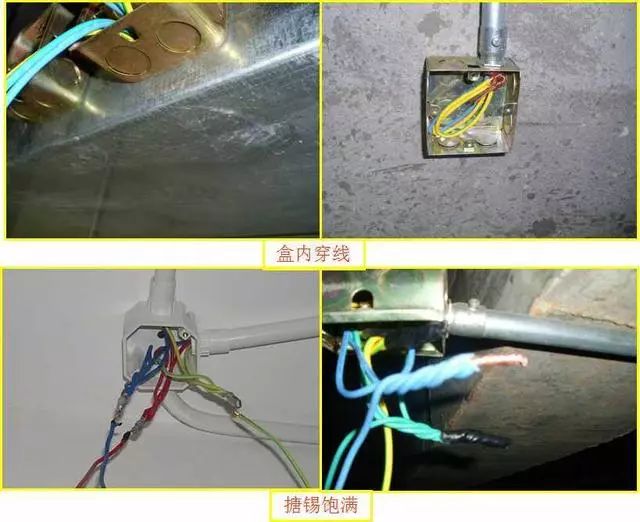

Threading in the pipe (1) before threading the steel pipe (wire pipe), first check whether the protective mouth of each pipe orifice is complete.

Green and yellow double color lines shall be used as protective ground wire, light blue is working zero line, and yellow, green and red are phase lines( 3) The rated voltage of insulated conductor passing through the pipe shall not be less than 450V.

When the conductor laid in the vertical pipeline exceeds the length, it shall be fixed at the nozzle and in the junction box.

7.

3.

The wires shall comply with the current technical standards issued by the state or the Ministry, have qualification certificates, and can be supplied according to the construction progress.

3.

Compared with wiring, threading in the pipe does not affect the decorative effect.

4.

All building decoration operations that will cause damage or serious pollution to the line shall be completed.

Cross with the main conductor of the branch line, make a circle section first to prevent falling off, and then wind it for 5 circles.

Winding method: suitable for branch connection of single core wire of 6mm2 and above.

During setting out, it shall be arranged while setting out, and there shall be no extrusion, back buckle, kink, damage to insulation, etc.

3、 Construction process 1.

the reserved length of the wire in the junction box, switch box, latch box and lamp cap box shall be 150mm.

2.

single core wire parallel joint: the conductor insulation platform shall be closed together, one of the cores shall be wound at the connection end for 5 ~ 7 turns at a place about 12mm away from the insulation platform, and then cut off, and the remaining ends shall be folded back and pressed on the winding line.

generally, threading method is adopted Φ 1.2 ~ 2.0mm iron wire or steel wire.

Then fold back the ends of the two wire cores, wrap them separately for 5 turns, twist them with the auxiliary wire for 2 turns, and cut off the remaining wires( 3) Branch connection of single core copper wire A.

b.

After adding auxiliary wires, wrap the binding wire in the middle of the merging part to both ends, and its length is 10 times the diameter of the conductor.

When the pipeline is long or there are many turns, the belt wire can be threaded while laying the pipeline.

After the disclosure is completed, the disclosure data shall be provided.

Reliable pipeline grounding and insulation to reduce the risk of electric shock.

1、 Construction method characteristics threading and wiring in the pipe has the following advantages: 1.

Therefore, it is necessary to grasp the appropriate temperature at any time according to many factors such as solder composition, quality and external ambient temperature.

d.

Conductor joints with different diameters: if it is a single (conductor section less than 2.5mm2) or multi-core flexible wire, it shall be rinsed with tin first, then the thin wire shall be crossed at 15mm away from the insulating layer on the thick wire, and the wire end shall be wound for 5 ~ 7 turns towards the thick conductor (single) end, and the thick conductor end shall be folded back and pressed on the thin wire.

Waterproof, moisture-proof, corrosion-proof and flame-proof.

When it is close to the wire core pair, stop the force, and then change the inclination angle of the knife surface to 15 °.

4.

A margin of 100 ~ 150mm shall be reserved at both ends of the pipeline.

Selection of conductor (1) conductor specification, model and quantity shall be correctly selected according to the requirements of design drawings( 2) The colors of phase line, zero line and protective ground wire shall be distinguished.

10.

After the branch wire is wound, cut off the remaining wire.

4.

Wire joints (1) tools and methods for exploiting insulation: A.

First bend one end of the iron wire into an unsealed circle, and then use the threading device to thread the belt wire into the pipeline.

b.

When the conductor is at the deformation joint, the compensation device shall move freely.

A certain margin shall be reserved for the conductor.

The common conductor is at the branch, and the conductor cannot be cut and passed directly.

conductors of different circuits, different voltages, AC and DC shall not be threaded into the same pipe.

d.

Oblique cutting method: use an electric knife at 45 °.

The length of the male coil is 10 times the diameter of the conductor.

c.

Pipe sweeping (1) the purpose of cleaning the pipeline is to remove dust, mud, floating rust and other sundries in the pipeline( 2) Method of cleaning the pipeline: bind both ends of the cloth strip firmly on the belt line, and two people pull the belt line back and forth to clean the sundries in the pipe.

6.

b.

5.

b.

The reserved length of outgoing conductor shall be 1.5m.

After threading, there shall be no ponding and moisture intrusion in the conduit, and the insulation strength of the conductor must meet the specification requirements.

c.

The civil engineering quality of buildings and structures related to threading shall comply with the current relevant provisions of construction engineering.

hinge method: applicable to single core wire below 4mm2.

c.

After a single coil is wound for 5 turns, cut off the remaining wire ends( 4) Connection of copper conductor in the connection box A.

8.

The electrical engineer shall make technical disclosure to the on-site construction personnel.

c.

8.

Winding method: there are two kinds of auxiliary wire and no auxiliary wire, which is suitable for the direct connection of single core wires of 6mm2 and above.

Hold the temperature when heating; Tin rinsing is not full when the temperature is too high; Tin rinsing is uneven when the temperature is too low.

9.

3.

the wires shall be bound according to the circuit.

Binding of conductor and strip line (1) the number of conductors is small, such as two to three.

The laying of insulated conductor through pipe is called threading in pipe.

This construction method mainly describes the threading construction technology of wire pipe in electrical engineering.

6.

Threading (1) while threading the tape, check whether the pipeline is unblocked, and whether the direction of the pipeline and the position of boxes and boxes meet the requirements of the design and construction drawings( 2) Threading method: A.

2、 Operating conditions 1.

b.

b.

7.

splicing method: suitable for single core wire connection of 4mm2 and below.

Copper wire welding (1) blowtorch heating (or electric furnace heating): place the solder in the tin spoon or tin pot, heat it with blowtorch or electric furnace, and weld after the solder melts.

Wire binding (1) first use rubber (or viscoplastic) insulating tape to wind 1 ~ 2 insulating tape widths from the intact insulating layer at the beginning of the wire joint, and then overlap with half the width..