Use high-quality putty to scrape and level the construction surface until the flatness meets the requirements.

After the roughing paint is completely dry, apply elastic finish paint with wool roller.

4.

Elastic roughening paint is a surface coating or intermediate coating paint with roughening effect prepared for personalized decoration.

In order to prevent uneven color and obvious splicing, the wall in each division line shall be constructed at one time, and the work shall be stopped at the wall corner or separation joint.

2.

During construction, avoid repeated roller coating in one person’s place, otherwise it is easy to get involved in bubbles to form pinholes.

Apply sealing primer and alkali resistant sealing primer for Exterior Wall twice, and the paint consumption is about 0.125kg/m ², The sealing primer shall be dried for 2-3 hours (under standard conditions) and the elastic roughening coating shall be applied.

Construction in hot weather must avoid direct sunlight on the wall, extend the drying time of paint film and avoid splicing.

The constructed elastic roughing paint shall have a drying time of 24h to prevent rework caused by being washed and broken by rain before drying…

After the putty is dry, polish it with appropriate mesh sandpaper.

Pay attention to the local weather forecast during construction.

Precautions 1.

For roller coating of elastic roughing paint, pineapple jacquard roller with appropriate aperture shall be used to dip in the elastic roughing paint, and the required pattern effect shall be evenly coated on the coated base surface.

3.

The elastic roughing paint must be tested before construction, and the large-area construction can be carried out after the effect is determined.

After the putty is polished, remove the surface dust and maintain it with clean water for 1-2 times.

It is widely used for the coating of internal and external walls of buildings and base surfaces such as lime and cement sand.

Apply putty.

The elastic finish paint is generally applied twice, and the unit consumption is about 0.23kg/m ²。 The final coating effect requires uniform overall color and pattern.

Be sure to roll the coating evenly to prevent roll leakage.

Elastic brushed paint has the following characteristics: 1) it is very artistic and three-dimensional; 2) Good weather resistance, mildew and alkali resistance; 3) Excellent elastic recovery and resilience, which can cover fine cracks; 4) Extremely high tensile strength and permanent toughness to prevent paint film cracking.

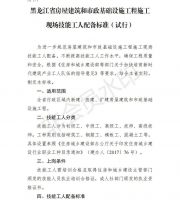

Process steps construction times (Times) coating amount (kg / M) ²) Drying time 25 ℃ (H) construction tools remarks: before construction, the dirt, dust and other attachments on the foundation surface shall be removed, and the construction putty construction shall be carried out after the foundation surface is dry Leveling primer construction of base surface such as guiding rule 10.1252-3 roller / wool brush / spray gun alkali sealing elastic middle layer roughening 10.7512 roughening roller modeling external wall elastic finish 20.36 roller / wool brush / spray gun surface effect base surface inspection before construction, carefully check the base surface and swing layer, which shall be dried for at least 4 weeks, with moisture content less than 10% and pH value less than 10; The base surface shall have sufficient strength and shall be flat, solid, free from hollowing and cracking.

According to different pattern sizes, the unit consumption of elastic roughing paint is about 0.75kg/m ²。 Apply elastic finish paint.