For important projects, special institutions need to be entrusted to measure the temperature expansion coefficient of both.

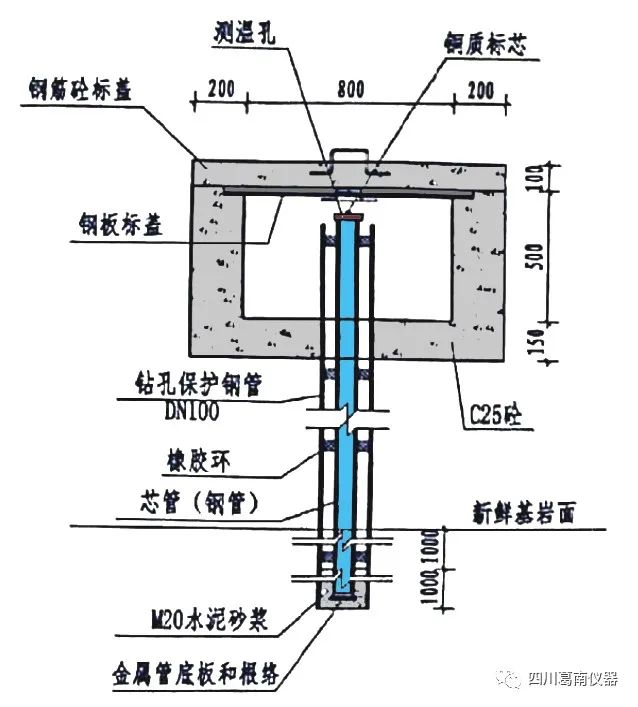

The drilling depth is based on the principle that the drilling to the dam foundation is relatively immovable.

On the one hand, it is because the characteristics of steel and aluminum pipes are different.

It is generally considered that the linear expansion coefficient of aluminum is twice that of steel (i.e α Aluminum = 2 α Steel), under the influence of the same temperature change, as long as the difference of deformation in the axial direction of two pipes with basically the same length is measured, the temperature correction can be calculated, so as to deduct the influence of temperature change on vertical displacement.

On the other hand, it can also eliminate the assembly dislocation of steel and aluminum pipes during installation.

The deformation of the steel pipe orifice relative to the orifice.

The Anzhao bimetallic standard pipe is 30m deep and the temperature variation is 10 ℃, with an error of 0.06mm.

Construction and observation of bimetallic markers for dam safety monitoring: dam deformation observation mainly includes the measurement of horizontal displacement and vertical displacement.

Taking the former, it is required that the error of vertical displacement should be controlled between 0.1 ~ 0.3mm.

Generally, the bimetallic standard pipe is hoisted one by one after the protective steel pipe is put into the borehole, then the protective steel pipe is lifted for 1m, and the 1:1 cement mortar is poured part by part between the protective pipe and the borehole, so that 1m at the bottom of the steel and aluminum pipe is buried in the concrete.

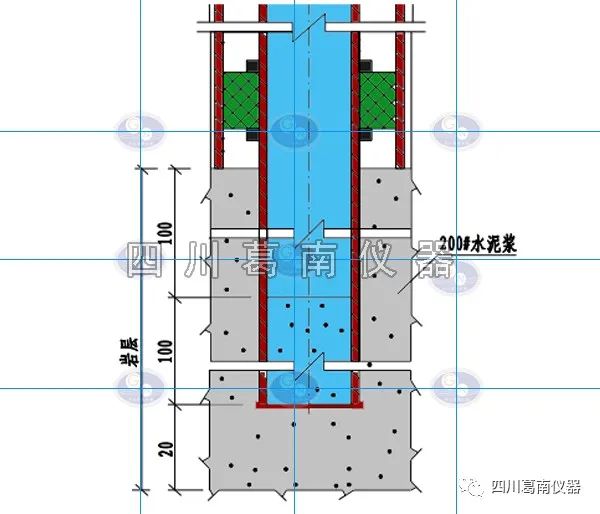

Bimetallic benchmark consists of 200mm drilling hole, 168d7 steel pipe for outer protection pipe and 89d7 steel pipe for inner measurement pipe.

Bimetallic protective pipe generally adopts seamless steel pipe with diameter of 168mm and wall thickness of 6 ~ 8mm, each section is 2 ~ 3M, the inner wall is smooth, and butt joint with male and female threads to facilitate the installation of steel and aluminum pipes.

1 principle of bimetallic standard Bimetallic marker refers to the installation of steel pipe protection pipe in the hole from the drilling of dam crest or gallery floor to the place where the vertical displacement of dam foundation can be ignored, in which aluminum pipe and steel pipe are installed, and the displacement of two pipe orifices relative to the orifice is measured respectively.

The value includes the sum of the settlement at the orifice and the temperature deformation of the steel pipe: H steel= ε+ε steel (1) Similarly, the deformation of aluminum pipe and orifice relative to the initial measured value: H aluminum= ε+ε aluminium (2) When α Aluminum = 2 α Steel, there are ε Aluminum = 2 ε Steel, substituted into equations (1) and (2) ε Steel = h aluminum-h steel, so the measured settlement each time: H steel- ε Steel = H steel-( H aluminum H steel) = 2H steel H aluminum 2 bimetallic bid construction The bimetallic marker is set in the geological conditions of the dam foundation.

Similarly, the steel pipe will also have an error of about 0.03mm.

It is likely that the above grouting method can not smoothly send the cement slurry to the hole bottom because the distance between the borehole and the outer wall of the protective pipe is small.

In order to solve this problem, the rubber centralizing ring between steel and lead pipes can be made into a dumbbell shape.

The hole diameter and hole depth are generally proposed by the engineering designer.

In fact, the deformation measured in this way is relatively small.

Each section of steel and aluminum pipes is generally 2-3m, which is connected with processed outer hoop joints.

In some engineering projects, we think that the orifice is the steel pipe protective orifice.

Some 8mm small holes are separated at the 1250px part at the bottom of steel pipe and aluminum pipe.

The steel pipe protective tube basically reaches the bottom of the hole, that is, the bottom has reached the depth where the vertical displacement is ignored, which cannot represent the settlement of the orifice…

The deformation observation team of the International Federation of Surveyors (fig) proposes that the error of the monitoring value should be less than 1 / 10 ~ 1 / 20 of the deformation.

For the sensor, we can choose instruments with higher measurement accuracy, improve machining accuracy and installation quality, reduce assembly error, and simply analyze the influence of linear expansion coefficient error of pipe.

According to the error transfer theory, the comprehensive error is 0.09mm, which is close to the error requirements.

The thread pitch of the connected screw thread can be processed differently from that of the steel pipe.

After the protective pipe, steel pipe and aluminum pipe are installed in place, it can be grouted down.

It is necessary to accurately measure the linear expansion coefficient of the pipe in order to obtain better observation data.

Bimetals are marked with single label and double label.

In the dam construction area, bimetallic markers are usually installed by drilling holes to provide working base points for dam vertical displacement observation.

It is generally believed that the coefficient of linear expansion of aluminum is 24 × 10-6, 23.8 in actual detection × 10-6.

Bimetallic steel and aluminum pipes can be installed side by side, or the two pipes can be sleeved on the same center.

Generally, the wall thickness of aluminum pipe shall be larger than that of steel pipe.

The measured value of each deformation is 2H steel-h aluminum.

It is also important to select the measuring point.

After the cement slurry is consolidated, check whether the grouting has been in place from the pipe orifice.

Bimetallic target steel and aluminum pipes need to be made of the same furnace materials to ensure the same physical and mechanical properties.

Aluminum pipes can also be processed in the same way.

3 observation and error analysis According to the specification, the vertical displacement of concrete dam foundation is about 1 ~ 3mm.

If the bimetallic standard pipe can be hoisted in one day, it can also be grouted into the borehole after the protective pipe is lifted for 1m before hoisting, and the steel and aluminum can be managed into the concrete before the cement slurry is solidified, which can solve the problem of insufficient grouting.

The steel pipe joint is connected with the steel pipe with screw thread and can be assembled in the factory, which can not only reduce the number of accessories, but also reduce the workload of on-site installation, and improve the installation quality and work efficiency.

Therefore, we believe that the bimetallic standard pipe is deep, the temperature variation amplitude is soft and large, and the deformation of the observation part is small.

The error of actual vertical displacement is caused by sensor, manual reading, linear expansion coefficient of bimetallic standard pipe and other factors.

During the actual operation, the deformation between the steel pipe and the orifice relative to the initial measured value shall be measured first.