The scientific, safe and rational utilization of underground space, foundation pit support will play an important role, and the proportion of its cost in the construction cost of the project will increase with the depth The geology and surrounding environment have changed greatly.

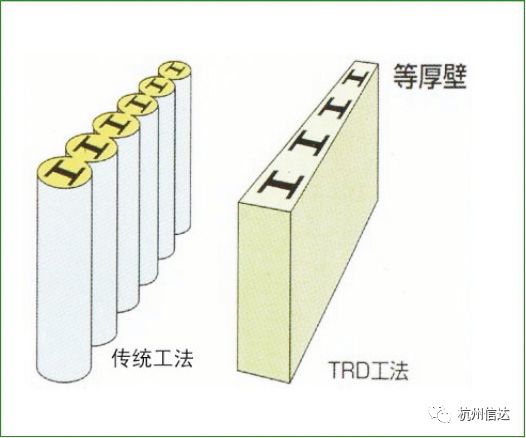

Figure 3 Compared with the traditional process, 1.2.3 the construction accuracy is high.

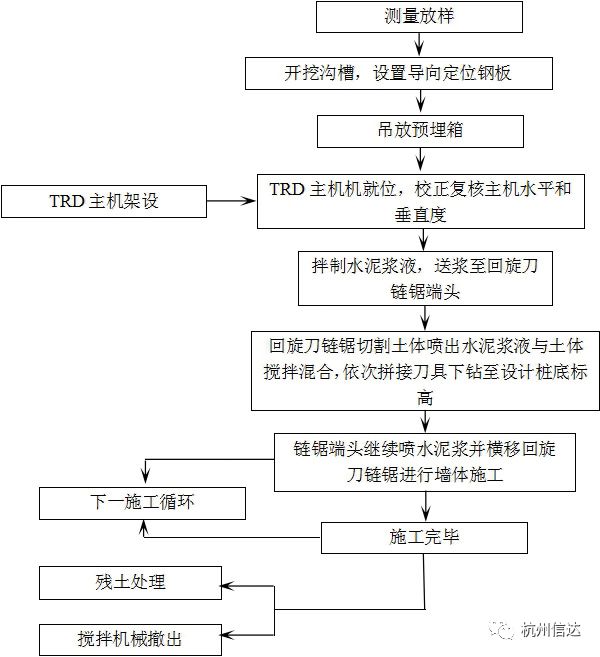

Classify according to whether the forward speed of the cutting box reaches a certain value, mainly including: 2.6.1 one cycle method: after drilling the cutting box to the predetermined design depth, directly start to inject the curing liquid, and advance the construction method of excavation and mixing to form a wall at the same time.

Figure 2 Construction status of TRD equipment 1.2.2 good wall forming quality and high construction efficiency.

A reinforcing plate with a thickness of ≥ 12 mm shall be welded on both sides of the section steel, and the size of the reinforcing plate is generally 400 mm × 300 mm, and the central opening shall be coaxial with the hole on the section steel..

At present, the deep foundation pit support in the industry generally uses technologies such as reinforced concrete diaphragm wall, bored pile + cement mixing pile water stop curtain, SMW construction method pile support system and cement reinforced soil diaphragm wall (TRD construction method).

Figure 5 TRD mixing pile wall construction process flow chart 2.1 survey and setting out, set out the pile position according to the design drawing according to the coordinate base point, set up temporary control piles, fill in the technical review form and submit it for acceptance.

2 construction process of TRD construction method TRD construction method three-step construction method: the first step is to inject cutting fluid for cutting when moving horizontally, and the cutting is terminated after a certain distance; Reverse switchback of the host (the second step), i.e.

It is a real “wall” rather than a “fence”.

While the rotary knife chain saw cuts the soil, the sprayed cement slurry is mixed with the soil to form a continuous wall under the cement soil with equal thickness.

The inner side of the foundation pit can be supported by steel pipe or reinforced concrete beam, Form an integral foundation pit support system.

During the excavation of the guide wall trench, the inner edge of the foundation pit enclosure shall be used as the control line, the excavator shall be used for excavation, the underground obstacles shall be removed, and the residual soil of the excavated trench shall be treated in time.

In order to ensure the accurate positioning of mixing pile and section steel, the guide wall shall be made before the construction of TRD pile.

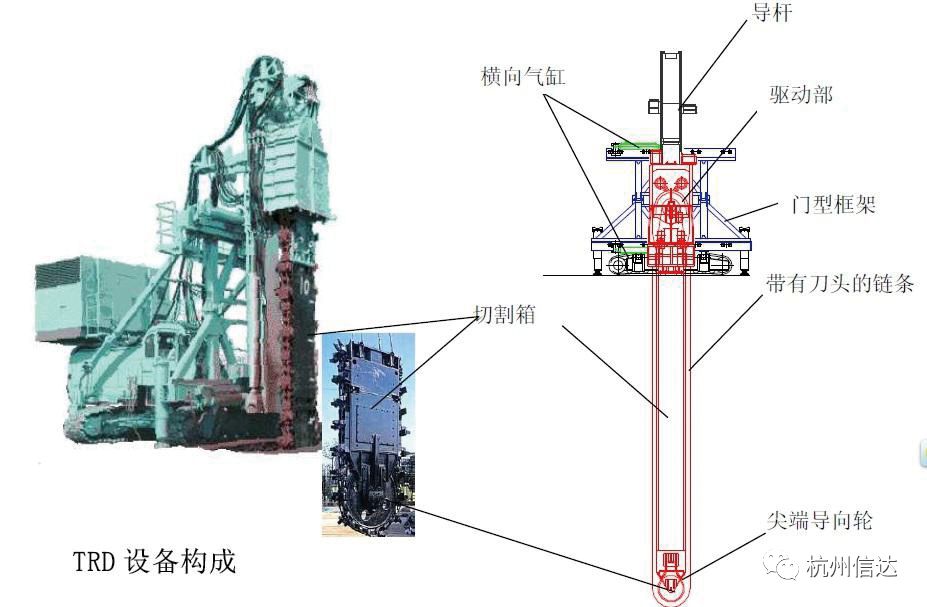

Figure 1 Characteristics of TRD construction method pile equipment and composition 1.2trd construction method the main characteristics of TRD construction method are as follows: 1.2.1 high stability and no rollover accident during construction.

In order to facilitate reuse and hoisting, a round hole shall be opened at the center from the top of the section steel, with a hole diameter of about 8 cm.

After the cutting box is driven to the design depth, install the inclinometer.

Through the multi-stage inclinometer installed in the cutting box, the vertical accuracy of the wall can be managed, and the accuracy within 1 / 250 can usually be ensured.

Figure 4 The real-time monitor 1.2.4 has strong adaptability.

Under this working condition, whether to inject the cutting fluid again can be selected according to the nature of the soil layer; The host machine returns to the positive position (step 3), and the bottom end of the box cutter is injected with curing liquid to mix and stir the cutting soil and curing liquid.

2.2 excavate the trench and set the positioning steel plate guide groove, which mainly plays the role of positioning and guidance, and is the key to control the verticality deviation of pile wall in TRD construction method.

2.6trd wall construction method When the inclinometer is installed and the main machine is connected to the cutting box and the test run is qualified, the cement slurry is mixed according to the design requirements and sent to the end of the rotary knife chain saw.

The wall is continuous and of equal thickness.

2.6.2 three cycle method: excavate first, withdraw the excavation and stir into the wall, that is, after the saw chain cutting box is drilled to the predetermined design depth, inject the excavation fluid at the same time, excavate for a distance first, then excavate and return to the beginning, and then inject the curing fluid to move forward and stir into the wall; 2.7 insert H-shaped steel.

Source: in case of infringement by Hangzhou Xinda, please contact to delete.

The chain drives the cutter to rotate up and down, digs out narrow and deep grooves underground, and injects cement slurry to form a real underground continuous wall.

Compared with the traditional construction method, the mixing is more uniform to ensure continuous construction, There is no bad bite to ensure high continuity and high water stop of the wall.

The H-shaped steel shall be selected and used according to the design requirements.

Figure 8 Connect with the cutting box 2.5 install the inclinometer.

Adjust the position of the host through the laser theodolite to ensure that the machine is stable and straight.

Figure 6 excavate the trench, set the positioning steel plate 2.3 lift the embedded box, excavate the embedded hole with a depth of about 3M, a length of about 2m and a width of about 1m with an excavator, and lift the embedded box into the embedded hole.

1.2.5 the wall quality is uniform.

Since the machine itself is equipped with automatic construction accuracy monitoring and deviation correction system, the data in X and Y directions of each depth of the cutting box can be monitored in real time through the construction management system during the construction process, manipulated and adjusted in real time, and the construction accuracy is not affected by the depth, so as to ensure the accuracy of wall forming.

With the continuous advancement of urbanization, the increasing scarcity of land resources and the soaring cost, people have to make maximum use of underground space.

moving in the opposite direction; During the moving process, the chain cutter rotates to further mix and stir the cutting soil.

It is suitable for places with limited height.

Compared with the traditional construction method, the chain saw head can be replaced according to the strength and hardness of the soil layer, which makes it more adaptable to the geology.

In general, the perpendicularity deviation shall be controlled within 5 ‰.

Then, as required, H-shaped steel shall be inserted as stress reinforcement material according to the design spacing before the cement soil hardens.

Hoist the cutting box section by section into the embedded hole, move the trd host to the embedded hole to connect with the cutting box, and then return the host to the predetermined construction position to cut the box into the excavation process by itself.

Therefore, it has high stability, good trafficability and no dumping.

TRD (trenchcutting re mixing deep wall method) was first successfully studied in Japan in the 1990s, and was introduced in China at the beginning of this century.

It can be applied to the soil layer with n value less than 100 blows, and can also be constructed in the gravel layer with particle size less than 100mm and the soft rock layer with unconfined compressive strength less than 5MPa.

Core materials such as H-section steel can be inserted at any interval, which can save construction materials and improve construction efficiency.

In the depth direction of the wall, the cement soil is mixed evenly, the strength dispersion of the cement soil is small, and the strength is improved.

During the construction of TRD method, the chain saw tool box is always vertically inserted into the stratum, the equipment height is only about 10m, the center of gravity is low, and the stability is good.

Figure 7 hoisting embedded box 2.4 the trd host is erected and connected with the cutting box.

It has been popularized in Shanghai, Hangzhou and other places successively.

The support system of a project in Zhuantang, Hangzhou supervised by our company is one of the successful application of cement reinforced earth diaphragm wall pouring construction method (TRD method).

1 working principle and characteristics of TRD construction technology 1.1 working principle of TRD construction technology TRD construction technology takes chain saw cutter as the main machine, vertically inserts it into the predetermined soil layer by using the connectable and removable chain saw cutter box, and then moves cutting and mixing along the horizontal direction.

According to the author’s understanding of TRD method technology, Combined with the supervision practice of the project, TRD construction method technology is introduced for your reference.

After the cement soil hardens, a section steel cement soil composite retaining wall with certain stiffness and strength shall be formed or only water stop shall be carried out, and then the supporting pile shall be constructed on the inner side of the cement wall for lateral pressure support.

Because it is applicable to all kinds of soil layers and gravel layers, it can be applied to all kinds of construction engineering, underground engineering, revetment engineering The foundation reinforcement and anti-seepage treatment of dams and embankments are more and more widely used due to the irreplaceable characteristics of other support systems.

Because these support system technologies are safe in theory and in practice The superior performance of maturity is more and more recognized in the industry, and its application scope is also expanded to housing construction, transportation, water conservancy, electric power and other engineering fields.