5.

This intelligent grouting function can monitor in real time, so as to improve the grouting stability and compactness and ensure the structural safety.

The prefabricated wallboard shall be vertically placed and transported.

When transporting vertical thin-walled members, special transportation frames shall be set; The corners of components and the contact between components and binding and support shall be protected by flexible cushion lining.

5.

The project is undertaken by the second construction group of Shanghai Construction Engineering Group.

After the on-site patrol alarm, it can automatically capture the face information of unqualified workers, feed back to the management platform in real time, and automatically form a patrol log.

※ Mobilization acceptance of prefabricated components 1.

WeChat official account changed the push rules.

The patrol inspection instrument imports the employment information of safety standard network and intelligent access control system into ar glasses, carries out real-time face recognition for on-site workers through ar glasses, the recognition time per capita is less than 3 seconds, and automatically alarms unregistered workers, which effectively solves the problems of low efficiency of manual patrol inspection and human error in real name registration.

6.

It is located in wsw-c2-14 plot in the main urban area of Lingang, with Moli road in the East, Fangzhu road in the south, Qiulian River in the West and Shengang Avenue in the north.

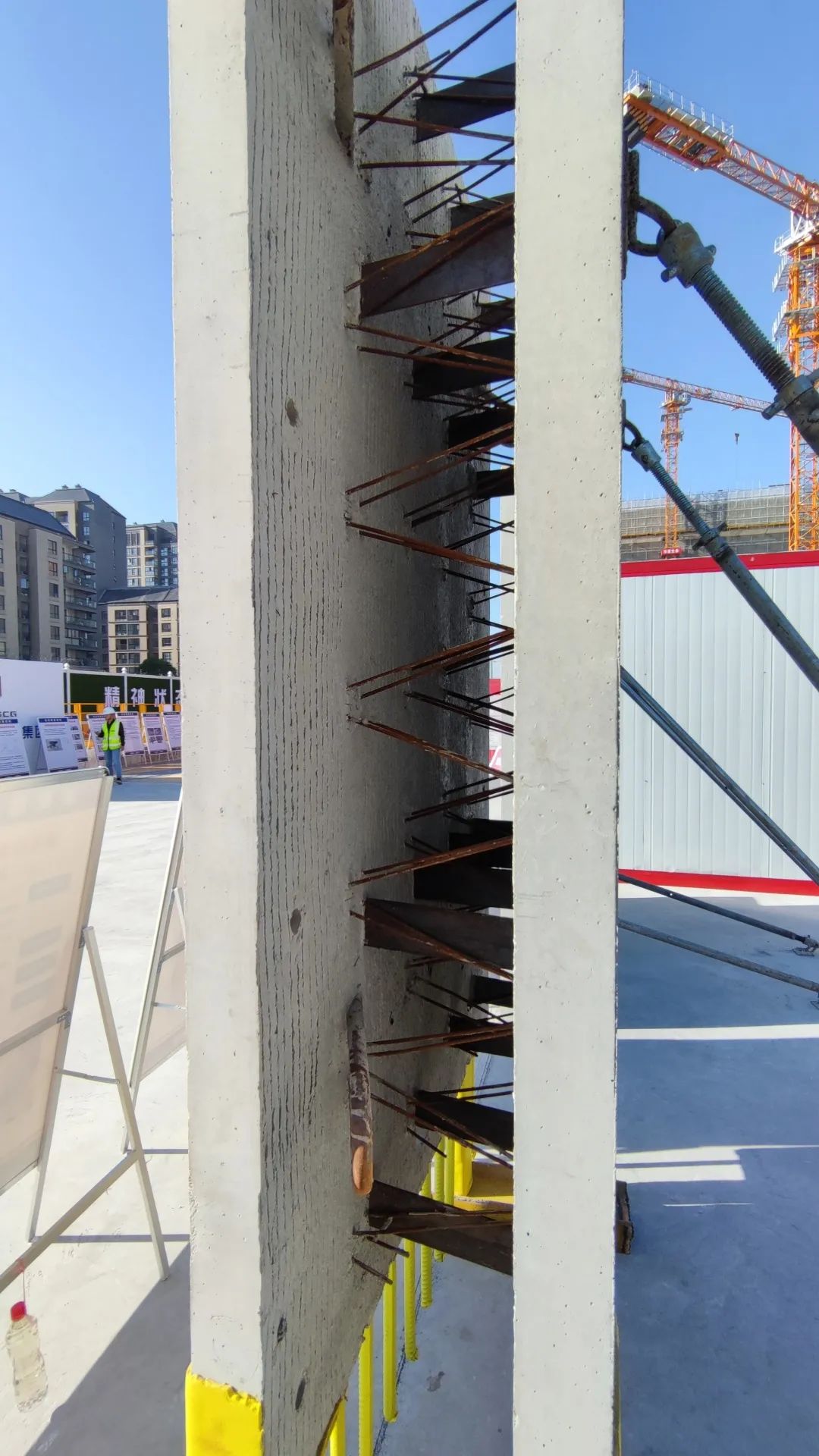

The concept of prefabricated construction for the exterior wall of basement structure can be realized by prefabricating double-sided laminated wallboard and truss reinforcement in the middle, which has good structural strength and anti leakage ability.

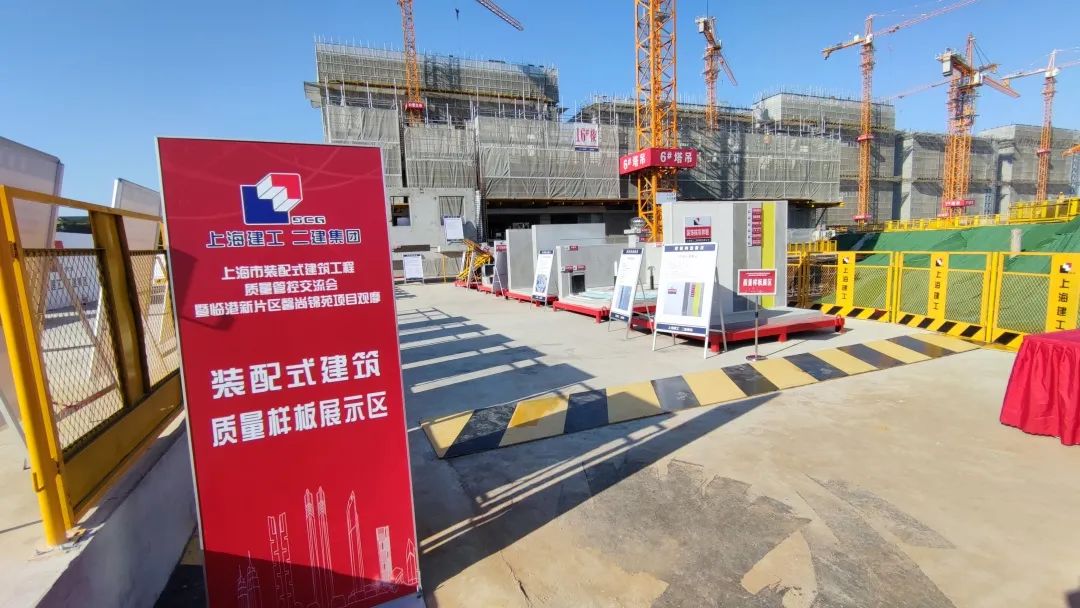

In response to the “quality month” activity in September, a quality control exchange and observation activity of fabricated engineering was held at this construction site, welcoming more than 1000 people to observe and observe on site.

The specific methods include: ① set tongue and groove at the horizontal joint of exterior wall panel components to solve the potential leakage of exterior wall panel structure joint; ② The elevation of the air-conditioning board is designed to be lower than the floor elevation of the indoor structure, and a drip line is set below the water retaining bucket at the Yanbian.

4.

and Shanghai Construction Engineering Group Co., Ltd.

The advanced prefabricated building construction systems such as the first sandwich insulation prefabricated enclosure PCTF system in China, the PCUs system with high-strength UHPC post cast connection joints and the steel plate truss double-sided superimposed shear wall spdw system that can be used for the prefabricated construction of basement structure are displayed on site, which completely eliminates the common quality problems of residential exterior wall leakage and avoids peeling off, insulation failure and other phenomena, Long term thermal insulation is realized.

Select transportation vehicles according to component size and weight requirements, and consider vehicle body balance during loading, unloading and transportation.

6.

Today, you came to Lingang xinshangjinyuan project, one of the largest residential building projects under construction in Lingang New Area.

Innovative use of AR patrol inspection instrument to build an intelligent safety management system.

At the exchange meeting held in the morning, many industry experts and representatives reported and exchanged on the technical quality, optimization measures and future improvement direction of PC prefabricated buildings in recent years, and put forward analysis and solutions to the common problems found in the quality inspection of prefabricated buildings carried out in the city since 2021, including the in-depth design of prefabricated buildings Source quality control of component manufacturers, transportation control of components, optimization of construction nodes on site, anti leakage measures, quality control and detection of structural connection and grouting, etc..

At the construction site, you saw the grouting demonstration of the operators: Step 1: use the hole cleaning blower to clean up the sundries in the grouting hole; Step 2: install the grouting detection pipe to detect the grouting compactness; Step 3: prepare grouting materials; Step 4: start grouting and complete it within four or five minutes.

3.

Precast columns, beams, laminated floors, balcony slabs, stairs and air conditioning panels shall be transported horizontally.

Zhang Min, President of the second construction group of Shanghai Construction Engineering Group, said that the second construction group will give full play to its advantages in prefabricated construction technology, continuously strengthen the whole process control and anti leakage control, and actively serve the construction of new areas near Hong Kong.

In addition, the prefabricated system that can be used for basement structure construction can be displayed and communicated.

Reliable fixing measures shall be taken to prevent members from moving or overturning during transportation.

The project site showed the labor real name management patrol inspection instrument independently developed by the second construction group.

When the wallboard with external finish is loaded, the external finish shall face outward and fixed with rope tightening device.

Prefabricated members that fail to pass the structural performance inspection shall not be used for concrete structures.

It is expected that the first batch of structural capping will be realized after the national day.

The floor in the air-conditioning Board shall be set with a good slope during component manufacturing; ③ The door and window frames of prefabricated components of exterior wall shall be embedded during component processing, the elevation of window sill plate shall be set with inner high and outer low, and the upper opening of window frame shall be set with drip line during component processing.

The prefabricated components shall not have dimensional deviation that affects the structural performance and installation and use function.

In order to strengthen epidemic prevention and control, online observation was also held, with more than 5000 visitors.

Prefabricated members shall be subject to structural performance inspection.

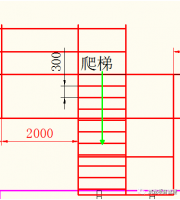

Scientific and technological innovation of prefabricated construction and strengthening process quality control ※ transportation of prefabricated components 1.

The project also uses the safety inspection applet to quickly determine the problem type, accurately locate the hidden danger location, and clarify the rectification unit and person in charge.

The on-site lightering road shall be flat and meet the requirements of bearing capacity.

The specification, position and quantity of embedded parts, dowel bars and reserved holes on the components (installation position and direction) shall meet the requirements of the standard drawing or design.

Carry out multi-level management of on-site safety problems and track the whole process of problem rectification.

At the same time, based on PCUs, a new fabricated frame structure system, the project can not only complete the construction quickly, but also have the advantages of short overlapping of reinforcement, wide application range, simple construction, convenient quality detection, easy concrete vibration and no bent construction compared with the traditional system.

4.

The flow rate, flow and pressure of traditional grouting can not be well controlled.

※ The application of intelligent grouting system for the installation of prefabricated components is the biggest highlight of this prefabricated construction demonstration project.

The Shanghai prefabricated construction project quality control exchange meeting was guided by Shanghai housing and urban rural construction management committee, hosted by Shanghai Engineering Construction Quality Management Association, and jointly undertaken by Shanghai Lingang New District Urban Construction Transportation affairs center, Shanghai port city development (Group) Co., Ltd.

For prefabricated members requiring structural performance inspection or physical examination, additional structural performance inspection report or component entity inspection report shall be provided.

3.

If you do not want to miss the wonderful content, please set the official account of the Shanghai site as the star sign and click “collection”, “look at” and “Zan” at the end of the text, so that you can see us for the first time.

The parts that exceed the allowable deviation and affect the structural performance, installation and use function shall be treated according to the technical treatment scheme, and re inspected and accepted.

Quality certificate of mobilization acceptance (product quality certificate and concrete strength inspection report).

2.

The appearance quality of prefabricated members shall be free of serious defects.

The construction of the whole project has reached 100% prefabricated construction, and the prefabrication rate of single building is 40%.

The acceptance of appearance quality and dimensional deviation of fabricated structure and the treatment of defects shall be carried out in accordance with the corresponding provisions of the specification.

2.

The production unit, component model, production date and quality acceptance mark shall be marked on the obvious parts of the prefabricated components.

The AR patrol inspection instrument is equipped with a visual management platform to automatically analyze and compare the data of the safety standard network and the access control system, so as to facilitate the project labor personnel to quickly sort out the employment information, find out the omissions and make up the deficiencies.

According to Jiang Jiming, chief engineer of the third engineering company of the second construction group of Shanghai Construction Engineering Group, anti leakage is the key quality control point of the project.

The existing serious defects shall be treated according to the technical treatment scheme, and re inspected and accepted.