Long press the QR code below to identify sister Mai Dang and ask you to work.

The position of the reserved tenon is generally left on the ground, and the reserved tenon shall be 20cm away from the internal and external corners.

In order to prevent the diversion of reinforcement, the protective layer of reinforcement on the upstream surface shall not be less than 50mm, the bottom plate reinforcement shall not contact the concrete cushion, the reinforcement shall not be fixed on the formwork with iron nails or lead wires, and it is strictly prohibited to use reinforcement as the cushion block of protective layer to prevent water from penetrating along the reinforcement.

Construction of cement mortar waterproof layer.

The disadvantage of flexible waterproof layer is that it is difficult to repair after leakage.

Flowers are elegant, water is true, and people are pure.

The embedded iron parts bear great stress.

If my heart is all right, how can I be; If people don’t love, how can you hurt.

Don’t judge a person with your own vision and cognition, and judge the right or wrong of a thing.

There shall be no bleeding and segregation before waterproof concrete pouring, and the free falling height shall not be greater than 1.5m; The waterproof concrete shall be mechanically vibrated and compacted; For continuous concrete pouring, one group (6) of impermeability test pieces shall be reserved every 500m3, and each project shall not be less than 2 groups; Waterproof concrete shall be naturally cured for at least 14 days.

Some things, work hard to know the results, struggle to know your potential.

The base treatment of rigid waterproof layer is very important.

External prevention and internal sticking method.

Introduction: how to do underground waterproof construction? Here are the main points! Construction of self waterproof concrete for maidangjie structure 1.

Life is not a battlefield, there is no need to compete.

After plastering, apply it on the surface of the cement slurry with a wet brush in sequence.

No dispute, no flattery, no beauty, no vulgarity.

If you have a problem, go to the guild leader.

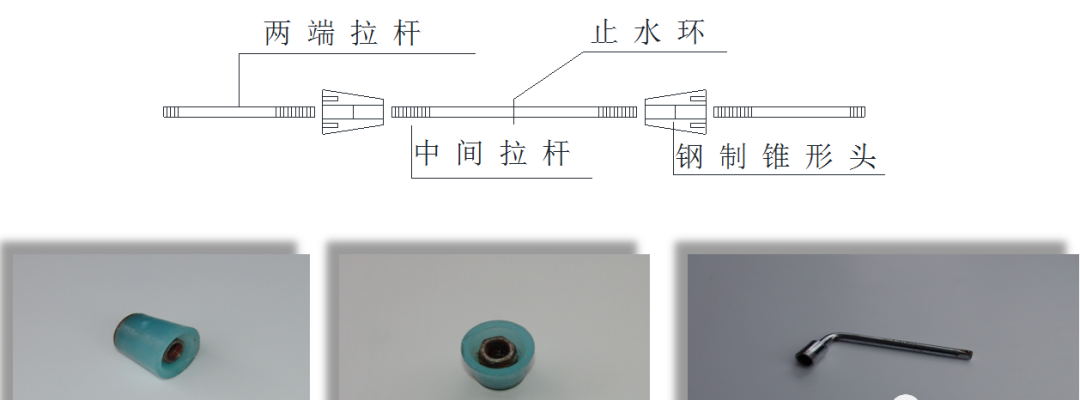

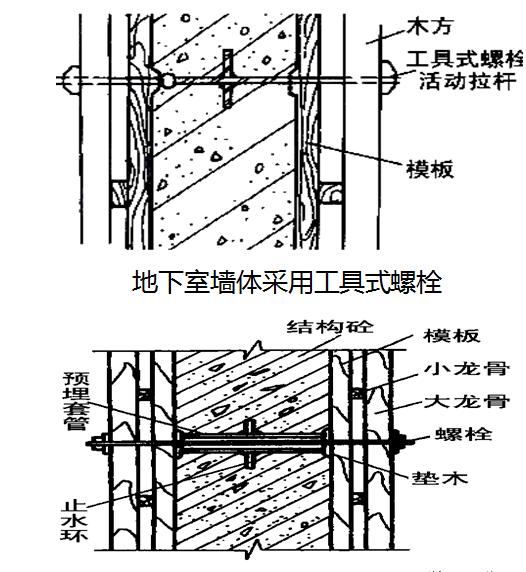

Generally, it is not suitable to fix the formwork through the concrete wall with bolts or iron wires.

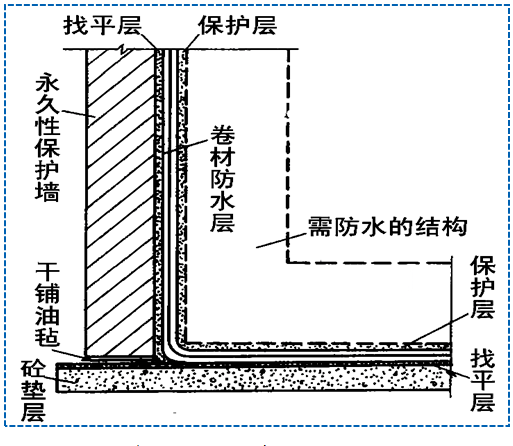

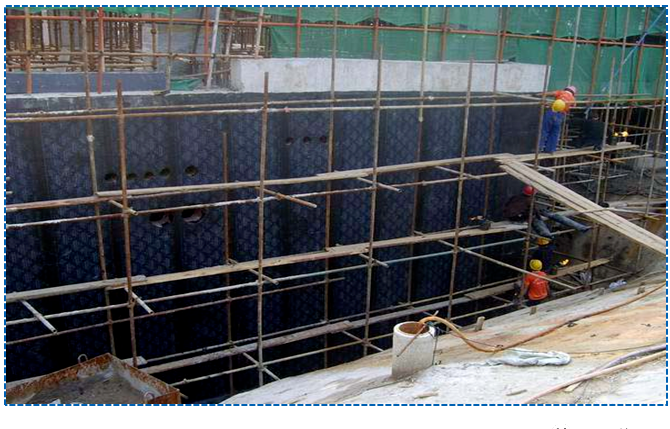

After pouring the concrete cushion, lay all the permanent protective walls, and lay the coiled materials on the cushion and permanent protective wall.

After the formwork is removed, the bolts shall be pulled out, the casing shall be sealed tightly with expanded cement mortar, and the pits left by the skid shall be sealed in the same way.

Not light a person, not waste a thing.

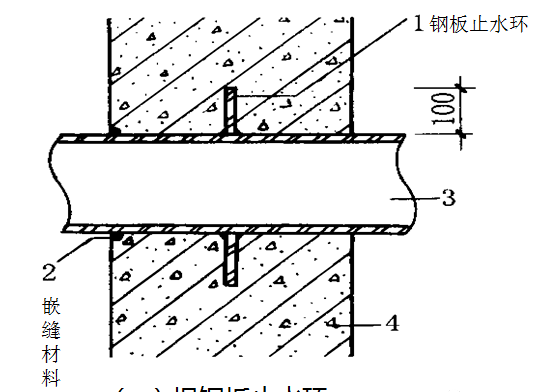

For example, tool bolts are used, water stop steel plates are welded in the middle of the bolts, and skids are set at both ends of the bolts.

Mix proportion requirements of waterproof concrete: the impermeability strength required by trial mix is 0.2MPa higher than the design value; The cement consumption shall not be less than 300kg / m3, and not less than 280kg / m3 when mixed with active admixture; The sand ratio should be 35 ~ 45%, and the water cement ratio should not be greater than 0.55; The slump shall not be greater than 50mm.

Embedded parts: the embedded iron parts on the basement wall or bottom plate shall be fixed with lifting parts or special tools to prevent water from penetrating into the room along the iron parts.

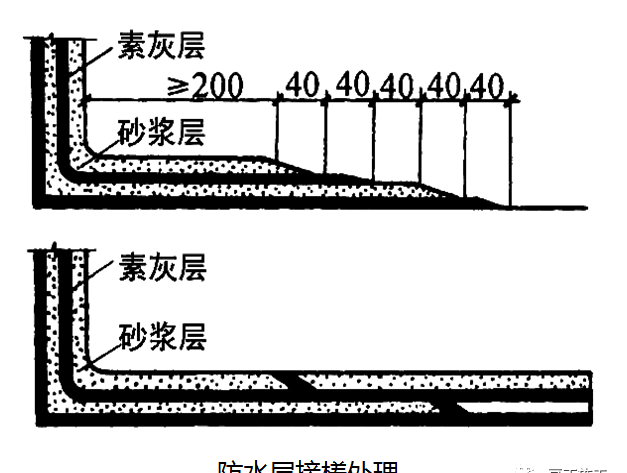

Edges, corners and unevenness exceeding 1cm shall be chiseled into a slow slope shape, watered and cleaned, and leveled in layers with plain ash and cement mortar.

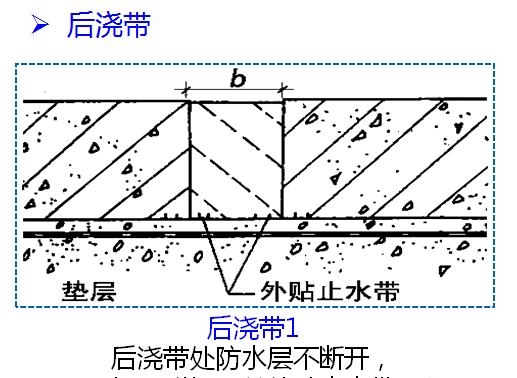

The horizontal construction joint of the wall shall not be left at the maximum shear force and bending moment or at the junction of the bottom plate and the wall.

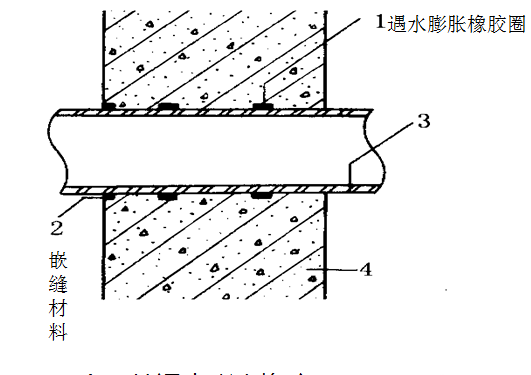

Through wall pipe treatment: when water supply and drainage, heating and cable pipes pass through the outer wall of the basement, waterproof treatment shall be done, otherwise it is very easy to seep water along the root of the pipe.

The waterproof layer of internal and external corners shall be plastered into round corners, with internal corner diameter of 5cm and external corner diameter of 1cm.

In fact, people should look down on themselves, less self, more transposition, in order to be happy..

Base treatment.

Method of tool bolt: fix and pull the waterproof bolt with tool bolt.

Firstly, apply a layer of 1mm thick cement slurry, scrape it back and forth with an iron trowel, fill the pores on the surface of the base course with cement slurry, and then apply a layer of 1mm thick cement slurry leveling layer.

Calm, so don’t hurt; Indifferent, so not angry.

Construction joint: construction joint is a weak waterproof part, which shall not be left or less left during construction.

See the figure below: 2.

Between people, more understanding will lead to less misunderstanding; Between hearts, more tolerance will reduce disputes.

Don’t expect others to have the same views as you.

Maidangjie waterproof mortar rigid waterproof layer construction rigid waterproof layer is applicable to the waterproof layer of underground masonry structure or the reinforcing layer of waterproof concrete structure.

External prevention and external sticking method.

Don’t expect others to fully understand you.

In order to prevent disturbing the surrounding concrete and damaging the waterproof layer, the thickness from the end of the embedded parts to the outer surface of the wall shall not be less than 25cm, and if it is less than 25cm, it shall be thickened locally.

Desire is the boiling water in the pot, the heart is the tea in the cup, the water boils because of the heat of the fire, and the heart is not surprised because of the coolness of the cup.

Madonna coiled material waterproof layer construction flexible waterproof layer adopts coiled material waterproof layer.

1.

The natural grading of coarse aggregate is appropriate, the particle size should be 5 ~ 40mm, and the mud content shall not be greater than 1%.

The useless value in your eyes may not be really useless.

The minimum horizontal construction joint shall not be less than 200mm from the bottom plate surface and 300mm from the edge of the through wall hole.

2.

Everyone’s value is different, there is no need to disdain anyone.

The cement mortar waterproof layer is made of pure water slurry and cement mortar by layer and cross coating.

Construction procedure: pouring cushion → building permanent protective wall → building 300mm high temporary protective wall → painting cement mortar leveling layer on the wall → paving additional waterproof layer at the corner → paving base plate waterproof layer → pouring base plate and wall concrete → cement mortar leveling layer of waterproof structure outer wall → construction of facade waterproof layer → acceptance and construction of protective layer.

The formwork of waterproof concrete works shall be flat, and the joints shall be tight without mortar leakage.

At present, polymer modified asphalt waterproof coiled material and synthetic polymer waterproof coiled material are selected in the waterproof engineering of underground engineering.

Waterproof detail treatment.

Pain comes from comparison, trouble comes from heart.

Don’t laugh at others’ efforts and don’t despise others’ achievements.

Key points of construction.

3.

1.

Materials and proportion of waterproof concrete.

The paving methods for the construction of coiled material waterproof layer are divided into two methods: external protection and external protection and internal protection according to the sequence with the construction of underground waterproof structure.

Method: the split bolt is additionally provided with casing, the casing has the function of supporting head, and the two ends of the casing are provided with skids.

Everyone has his own personality and views.

The second cement mortar layer, with a thickness of 6 ~ 8mm, is carried out after the initial setting of the cement mortar layer, so that the cement mortar is thinly embedded into 1 / 4 of the thickness of the cement mortar layer.

When the structure is subjected to strong vibration load or corrosion, high temperature and repeated freezing and thawing, it should not be used.

The number of times of coating the waterproof layer is determined by the design, and the more common method is 5 times.

2.

The bottom slab concrete shall be poured continuously, and vertical construction joints shall not be reserved on the wall.

See the above figure on the right: the embedded casing is welded with water stop ring.

People often think too much of themselves before they worry about gain and loss, and feel that others must understand themselves.

Life needs light, light and long fragrance.

The above layers are carried out alternately.

When bolts are required to fix the formwork through the concrete wall, water stop measures shall be taken.

The facade waterproof coiled material is directly laid on the outer surface of the outer wall of the waterproof structure.

In order to ensure the convenience of waterproof construction and pipeline installation, the pipeline position shall be 25cm away from the inner wall corner or protruding part, and the spacing between pipes shall be greater than 30cm.

See the figure below: for honeycomb holes on the concrete surface, loose stones shall be removed first, watered and cleaned, and plastered alternately with plain ash and cement mortar to be level with the base surface.

Base course treatment includes cleaning, watering, brushing and leveling to keep the base course surface wet, clean, flat, solid and rough.

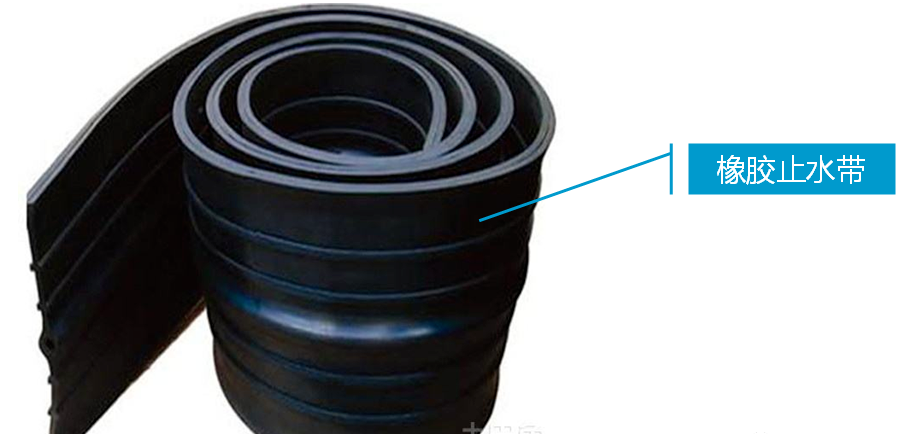

Deformation joint waterstop: at present, embedded rubber (plastic) waterstop is widely used.

When desire meets cold and precipitates in the heart, it will not be bothered or annoyed.

Light in true taste, light in true fragrance.

Method of bolt and plug: make grooves around the bolts on both sides of the structure, cut off the flat groove bottom of the bolt after formwork removal, and then block the groove with expanded cement mortar.

Its ability to resist deformation is poor.

The first layer of plain ash layer is 2mm thick.

The construction joint of the waterproof layer shall be provided with a slope stepped tenon, and the overlapping of the tenon shall be overlapped layer by layer according to the hierarchical operation sequence.

When removing the formwork, remove the tool bolt, and then seal the bolt groove tightly with caulking material and polymer cement mortar.

During backfilling outside the wall, the through wall pipe protruding outside the wall shall not be punched or rammed to avoid water leakage due to impact of waterproof measures.

The type of cement shall be selected according to the design requirements, and its strength grade shall not be lower than grade 32.5.

During concrete pouring, the through wall pipe shall not be impacted, vibrated and embedded.