The post cast strip of (E-D and T-U) axis is reserved in the project block to solve the problems of shrinkage deformation of reinforced concrete and reducing temperature stress.

Overall effect drawing of the project foundation pit overview of the project the project covers an area of 38546 ㎡, with a total construction area of about 135785.22 ㎡, 105880.34 ㎡ underground and 29904.88 ㎡ above the ground.

1 enclosure structure and pit division design due to the special geographical location of the project, it is close to the moat in the East, zhangjiaxiang River in the north, and close to Metro Line 1.

Bin Division: the plane size of basement structure is 140m × 309m, the first floor and the second floor of the underground are planned to be divided into a / B / C3 regions.

2 support system design support system: ① three concrete supports are adopted for the foundation pit of the block, of which the first support is also used as the excavation and material stacking platform; ② ③ block adopts the support form of one concrete support + three steel supports, and the steel support adopts prestressed servo system; ④ The block is supported by two layers of concrete; The support system adopts the support system of opposite brace, corner brace and side truss, and the vertical support structure system of horizontal support system is steel column with bored cast-in-place pile.

With this construction scheme, the fierce temperature difference and dry shrinkage at the initial stage of construction can be avoided, the temperature expansion stress during construction can be greatly reduced, the cracks can be effectively controlled, and the construction progress can be accelerated.

Foundation pit support profile drawing support model drawing due to the large construction area of the foundation pit, the project department has made a comparative analysis on the construction scheme to solve the problem of how to prevent through cracks and control structural surface cracks after concrete structure construction, and combined with the successful experience of canceling the post cast strip and changing to “jumping warehouse method” in many projects in recent years, After the research and demonstration of the group company and the project department, the optimization suggestions are put forward, and it is decided to retain two post cast strips, cancel other temperature post cast strips, replace the original design post cast strip and expansion reinforcing strip construction method, and adopt the “jump BIN method” for construction.

(2) The long construction period of the post cast strip and the long-term retention of the bottom support bent are avoided, which provides construction space for the next process and saves the cost.

The division of the second floor and the first floor of the underground is shown in the following figure: negative II For the positive and negative zero construction of basement, considering the problems of temporary storage yard such as concrete pouring, reinforcement and woodworking shed, it is planned to complete the non stack bridge slab area first and remove the non support beam area first; After the basement roof in the unsupported area is poured and formed, the material storage yard shall be gradually transferred.

There are enough construction flow sections to organize “jump BIN method” construction.

The reserved positions are mainly based on the combination of cushion cap position, single block pouring concrete floor area, earthwork excavation progress, support section removal and other factors.

The stress release time in the first pouring area is sufficient, and the concrete on both sides is more closely combined, which is conducive to the construction and improves the construction efficiency.

Three floors underground and two floors above ground.

In such a construction environment, the temperature stress in the construction stage is much greater than the tensile capacity of concrete materials, so it is difficult to resist completely by the method of resistance.

Raw material control the beam and slab of the project adopts C35 commercial concrete, the 60d strength of concrete is used as the index, and the slump is controlled at 150 ± 30mm.

Considering the concrete pouring problem in the front slab area of the station, the middle part shall be removed first.

Effect drawing of foundation pit support area ① of the large pit shall be excavated first.

The project adopts pit division construction, which is divided into four blocks: ① and ④ the enclosure structure of blocks mainly adopts the support form of bored cast-in-place pile + CSM water stop curtain + underground continuous wall, ② ③ 1000mm thick underground diaphragm wall and I-shaped steel joint are adopted within 50m protection range of the block adjacent to the subway; The groove section of underground continuous wall is reinforced by triaxial mixing pile, and the skirt of triaxial cement soil mixing pile is set in the pit for reinforcement.

(4) By optimizing the concrete mix proportion, controlling the quality of raw materials, concrete molding temperature and slump, and strengthening the secondary vibration and secondary plastering during concrete pouring, the shrinkage cracks of concrete are reduced, the compactness and tensile strength of concrete are improved, and the hidden dangers of leakage are reduced.

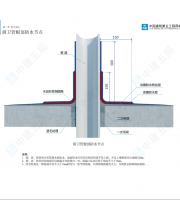

(3) The skip warehouse method is adopted for construction, that is, the overall structure is segmented according to the construction joint, poured at intervals (one section is poured after jumping off), and then filled and poured into a whole after not less than 7 days.

The principle of concrete material control and mix proportion design is to improve the tensile strength as much as possible under the condition of ensuring that the compressive strength meets the requirements, and reduce the temperature shrinkage and drying shrinkage of concrete from two aspects of reducing the amount of cement and water consumption..

3.

The perimeter of the foundation pit is 988m, and the excavation depth of the foundation pit is 18.45 ~ 21m.

(2) The temperature and humidity of underground works change greatly during construction, while the temperature and humidity change slightly in the normal use stage after underground backfill.

After the formation of the underground floor of area ①, the underground main structure of area ②, ④, construction area ② and ④ shall be excavated.

(5) The construction of jump warehouse method makes the structural integrity form in advance, which is conducive to the early intervention of basement transportation machinery, convenient material turnover and transportation, and improves the construction efficiency.

The successful implementation of the “jump warehouse method” in the project also provides a practical basis for reference and learning for everyone.

The construction scheme of “warehouse hopping method” is implemented.

Tip: click “love civil engineering” above ↑ to join Originated from Nantong second construction group, with the popularization and application of “jump warehouse method” construction technology, this construction technology integrating multiple advantages is gradually replacing the traditional construction technology of retaining post cast strip.

Warehouse hopping procedure 1 warehouse hopping procedure 2 warehouse hopping procedure 3 warehouse hopping procedure 4 1 “warehouse hopping method” construction technology advantages (1) through the warehouse hopping construction method, the post cast strip is changed into construction joint, the construction process is simple and the construction period is shortened.

(3) The pouring time of the sub warehouse block is about 7 days.

Concrete crushed stone grading: 5 ~ 40mm continuous grading; The mud content is less than 0.5%; Sand for concrete: medium sand with modulus fineness of 2.8 ~ 3.0; The mud content is less than 1.5%.

The warehouse hopping construction scope of the project is above the negative three floors of roof.

The foundation form is pile raft foundation, the main structure form is frame structure, and the roof is slope roof.

After the concrete pouring of this part is completed, it shall be removed from the middle to both sides, pouring one area and removing one area; Considering that some parts cannot be poured with sky pump, it is proposed to use ground pump for pouring.

This shows that the environmental conditions of underground engineering are most suitable for “jump warehouse method” construction.

Construction sequence diagram of positive and negative zero structure non stack bridge slab area Construction sequence of non stack bridge slab area with positive and negative zero structure figure 4 construction technical measures of “jumping warehouse method” 1.

The maximum size of one side of skip block shall not be greater than 40m × 40m, the pouring interval of adjacent concrete blocks shall not be less than 7d, and the jump joint shall meet the requirements of construction joint.

A is divided into 11 blocks, B is divided into 10 blocks and C is divided into 6 blocks.

After short-term stress release, several small blocks are connected as a whole to resist the temperature shrinkage stress in the lower section by relying on the tensile strength of concrete.

Temporary construction joints are set between blocks.

After the formation of the underground floor of area ② and ④, the earthwork of area ③ shall be excavated and the main structure of area ③ shall be constructed.

Construction example of “jump BIN method” 2 feasibility analysis of “jump BIN method” construction of the project (1) the project is an ultra long concrete structure with three underground floors and a construction area of 40000 m2.

The method of “resistance and release”, “release first and then resistance”, and finally “resistance first” should be adopted.

Construction principle of “jump BIN method” construction principle of “jump BIN method”: the super long concrete block is divided into several small blocks with non cracking calculated length as the bin size for interval construction.

In the large-scale deep foundation pit project of Suzhou renhengcang Street project of Nantong second construction group under complex conditions, the “jump warehouse method” is used to replace the “post cast strip” construction, which solves the safety and quality problems left by the traditional post cast strip.