Make a waterproof protective layer outside the waterproof layer.

The treatment of screw hole on the inner wall of the structure is the same as that on the outer wall.

6.

Expand the outer hole into a 20mm deep horn mouth as far as possible.

The middle of the screw needs to be welded with 2 thick 70 × 70mm waterstop.

Firstly, chisel the screw hole into a horn shape with a depth of 15mm and a diameter of 30mm, and pour 1:3 cement mortar.

6.

2.

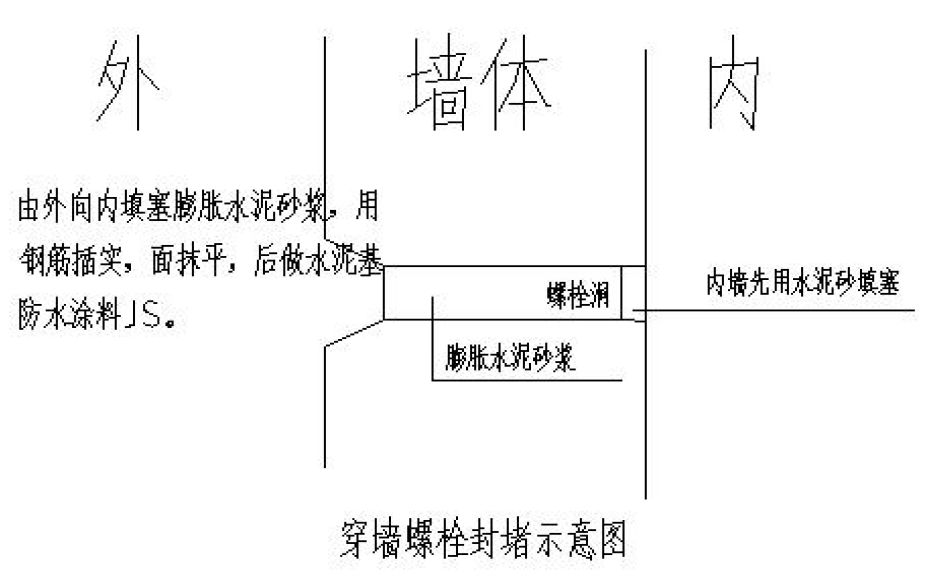

The plugging of through wall screw holes involves the leakage risk of the external wall, which must be paid attention to in the construction.

Spray water on the exterior wall with a watering can to keep the surrounding of the bolt hole wet.

(6) After the acceptance of waterproof layer and protection and waterproof additional layer, the polyurethane waterproof film with a thickness of not less than 2mm or coiled material with a thickness of not less than 4mm shall be constructed on the upstream surface.

Process flow: remove the plastic cushion block – cut off the screw – brush antirust paint – watering and wetting – internal and external blocking – waterproof additional layer – waterproof layer and protection – internal facing node diagram: structural method: (1) remove the plastic cushion block and remove the internal and external plastic cushion blocks one by one.

Process flow of screw hole plugging of external wall 1.

During operation, the other end can be grouted and blocked only after the mortar at the first end is solidified .

Quality control points: (1) disposable water stop split screw and water stop sheet (2) cutting depth of split screw (3) brush antirust paint on both sides (4) wet groove (5) polymer cement mortar troweling and calendering (6) scope and thickness of waterproof additional layer (7) key precautions for construction process of waterproof layer and waterproof protective layer 1.

5.

A large number of through wall screws are used in the construction of the external wall of shear wall and frame shear structure.

(7) Internal finish: the internal finish shall be constructed after the construction of waterproof layer outside the wall is completed.

Use an iron trowel to plaster the expansion cement mortar (the content of expansion agent is 4% ~ 5% of the cement content) to the bolt hole from the outside to the inside of the outer wall.

Let’s come to the construction site to see how the screw holes in the outer wall are blocked for exchange and discussion.

Before the construction of waterproof layer, the grooves at the screw position shall be compacted and leveled with 1:2 polymer cement mortar one by one.

5.

4.

3.

Initially block the inner wall with cement mortar, and then start to block the outer wall holes after solidification.

Before formal construction, the template shall be constructed first, and the mortar mix proportion shall be listed to indicate the dosage of various materials.

After solidification, cement-based waterproof coating JS with thickness of 1.5mm and diameter of 150mm shall be applied around the bolt hole of the outer wall.

(3) Water and wet, clean the sundries in the hole, and water and wet the periphery.

Loose concrete at hole edge must be chiseled off.

4.

Before plugging, after the garbage in the hole is cleaned and water is sprinkled to wet the hole, the mortar can be filled only after the acceptance of the project quality inspector.

(4) Plug the inner and outer screw holes with polymer cement mortar and compact and trowel them.

Remove and clean the PVC pipe in the wall with impact drill, and clean the residual mortar around the hole.

Site construction example: take out the PVC plastic sleeve ▲ expand it into a bell ▲ fill it with cement mortar ▲ plug the completed bolt hole with reinforcement mortar ▲ fill the completed bolt hole ▲ after the waterproof construction ▲ description of the treatment method of water stop screw node: the screw used to fix the formwork must use a one-time water stop split screw.

After pouring in a part, tamp it with a reinforcement rod with a diameter of 10, fill and tamp it repeatedly, and finally trowel and polish the bolt hole with an iron trowel.

The disposable water stop split screw can be a tool screw or a screw plus a conical plastic cushion block to leave a groove at the end of the screw.

(5) Waterproof additional layer: after the polymer cement mortar is dried (about 24 hours), construct the waterproof additional layer at the screw position on the upstream side of the wall, with an additional layer range of 100 × 100mm。 The waterproof material and method are the same as that of waterproof layer.

3.

(2) Cut off the excess screw and cut the screw from the deepest part of the groove.

2.

When conical plastic cushion blocks are used at both ends of the disposable through wall screw, the plastic cushion blocks shall be removed one by one inside and outside the wall after maintenance, and then the screw shall be cut from the deepest part of the orifice.

The expansive cement mortar shall be mixed intensively, and it is forbidden to mix directly on the floor.

The quality inspector shall track and check the filling quality in the process, and issue a rectification notice in time and report it if it is found that the filling is unqualified.