It is not suitable to set two or more joints for the same longitudinal stressed reinforcement

.

② The joint should not be set in the stirrup densification area of beam end and column end of frame with seismic fortification requirements; when it cannot be avoided, the mechanical joint with equal strength and high quality should not be more than 50%

.

In the construction site, the mechanical properties of mechanical joint and welded joint specimens of steel bars shall be inspected according to the current national standard “general technical specification for mechanical connection of steel bars” jgj107 and “Specification for welding and acceptance of steel bars” jgj18, and the quality shall comply with the relevant regulations

.

The welding shell can be knocked properly, and the joint and welding edge shall be checked to see whether they are even, full and smooth, without cracks, collapse, undercut, slag inclusion, obvious burn and other defects on the surface of the reinforcement, the deviation of the reinforcement axis at the joint shall not be more than 1 / 10 D and not more than 2 mm, and the initial bending of the joint shall not be more than 4 degrees

.

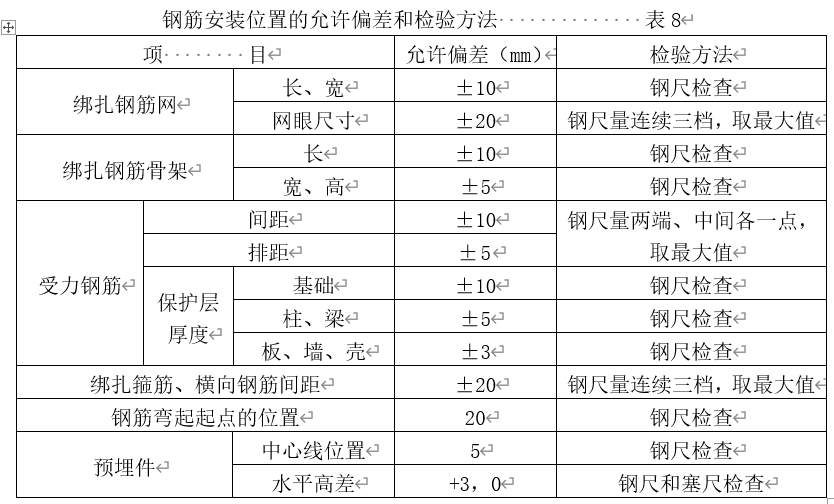

(4) the shape and size deviation of reinforcement processing shall meet the design requirements, and the deviation shall meet the requirements in the table below

.

For beams, columns and independent foundations, 10% and no less than 3 components shall be inspected; for walls and slabs, 10% and no less than 3 representative natural rooms shall be inspected; for large space structures, the walls can be divided into inspection surfaces according to the height of about 5m between adjacent axes, and the slabs can be divided into inspection surfaces according to the vertical and horizontal axes, 10% and no less than 3 surfaces

.

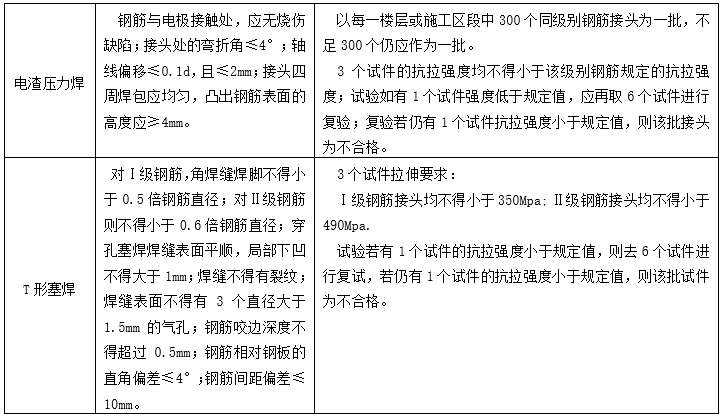

(1) welding joint quality inspection 1) electroslag pressure welding: remove oil, rust, etc., the flux should be moisture-proof, if it is damp, it should be dried, and the operator should pay attention to the flux loading and compaction in the project

.

The inspection quantity is within the same inspection lot

.

4) Stirrups should be provided according to the design requirements within the lap length of longitudinal stressed reinforcement of beam and column components

.

(2) reinforcement joint setting 1) the joint of stressed reinforcement should be set at the place with less stress

.

3) When the steel bar is bent no more than 90 degrees, the inner diameter of the bending arc at the bending point shall not be less than 5 times of the diameter of the steel bar

.

The transverse clear distance of reinforcement in binding lap joint shall not be less than the diameter of reinforcement and shall not be less than 25 mm

.

Click architecture to pay attention to me ☀ Architecture: solidified history ☀ Through architecture, we see the heritage and rise and fall of civilization; through architecture, we create the present and future of civilization

.

The inspection quantity is within the same inspection lot

.

2) When 135 ° hook is required at the end of reinforcement in the design, the inner diameter of bending arc of HRB335 and HRB400 reinforcement shall not be less than 4 times of the diameter of reinforcement, and the length of straight part after bending of hook shall meet the design requirements

.

(3) the steel bar straightening should adopt mechanical method or cold drawing method

.

2) When mechanical connection or welding joint is used for stressed reinforcement, the joints set in the same member should be staggered

.

The minimum lap length of binding lap joint of longitudinal stressed reinforcement shall comply with the provisions of Article 2 below

.

2) The bending angle of stirrup hook: for general structures, it should not be less than 90 ° and for structures with seismic requirements, it should be 135 °

.

2) During flash butt welding, the appropriate welding process shall be selected according to the diameter of the steel bar

.

In the same connection section, the joint area percentage of mechanical connection and welding of longitudinal load-bearing reinforcement is the ratio of the section area of longitudinal load-bearing reinforcement with joint to that of all longitudinal load-bearing reinforcement

.

The length of the connecting section of the steel bar binding lap joint is 1.3ll (ll is the lap length)

.

3) The length of straight part of stirrup after bending: for general structures, it should not be less than 5 times of stirrup diameter; for structures with seismic requirements, it should not be less than 10 times of stirrup diameter

.

5.4.6 of GB 50204)

.

reinforcement processing (1) the hook and bending of stressed reinforcement shall meet the following requirements: 1) 180 ° hook shall be made at the end of hpb235 reinforcement, the inner diameter of bending arc shall not be less than 2.5 times of reinforcement diameter, and the length of straight part of hook after bending shall not be less than 3 times of reinforcement diameter

.

The length of mechanical joint and welding joint of longitudinal stressed reinforcement is 35 times of D (D is the larger diameter of longitudinal stressed reinforcement) and not less than 500mm

.

In the same connection section, the area percentage of longitudinal reinforcement lap joint is the ratio of the section area of longitudinal stressed reinforcement with lap joint to the section area of all longitudinal stressed reinforcement in the section (Fig

.

The connection mode of longitudinal stressed reinforcement shall meet the design requirements

.

When there are no specific requirements in the design, the following provisions shall be met: ① the diameter of stirrups shall not be less than 0.25 times of the larger diameter of the lap reinforcement; ② the stirrup spacing in the tensile lap section shall not be greater than 5 times of the smaller diameter of the lap reinforcement, and shall not be greater than 100 mm; ③ the stirrup spacing in the compressive lap section shall not be greater than 10 times of the smaller diameter of the lap reinforcement, and shall not be greater than 200 mm; ④ when the column is in the longitudinal direction When the diameter of the stressed reinforcement is greater than 25 mm, two stirrups should be set within 100 mm outside the two end faces of the lap joint, and the distance between them should be 50 rum.

.

(2) in addition to welding closed ring stirrup, the end of stirrup shall be used as hook, and the hook form shall meet the design requirements; when there are no specific requirements in the design, the following provisions shall be met: 1) the inner diameter of stirrup hook shall not be less than the diameter of stressed steel bar in addition to meeting the specification

.

③ The welded joint should not be used in the structural members directly bearing the dynamic load; when the mechanical joint is used, it should not be more than 50%

.

Before welding, the end of the steel bar shall be straight, rust and dirt shall be removed within 150 mm, and the deviation of the two axes shall not exceed 0.5 mm

.

2、 The commonly used reinforcement connections include mechanical straight thread connection joint, electroslag pressure welding joint, flash butt welding or arc welding joint and binding joint

.

All joints whose joint midpoint is within the length of the joint section belong to the same connection section

.

The unqualified joint shall be cut off and re welded

.

The column connection joint can refer to the drawing rules and structural details of concrete structure construction drawing (16g101)

.

The distance from the end of the joint to the bending point of the reinforcement shall not be less than 10 times of the diameter of the reinforcement

.

In the same connection section, the joint area percentage of longitudinal stressed reinforcement shall meet the design requirements; when there are no specific requirements in the design, the following provisions shall be met: ① in the tensile zone, it shall not be greater than 50%

.

All the lap joints whose midpoint is within the length of the connecting section belong to the same connecting section

.

3) The binding lap joints of adjacent longitudinal stressed reinforcement in the same member should be staggered

.

When the cold drawing method is used to straighten the reinforcement, the cold drawing rate of hpb235 reinforcement should not be greater than 4%, and that of HRB335, HRB400 and rrb400 reinforcement should not be greater than 1%

.

In the same connection section, the area percentage of longitudinal tensile reinforcement lap joint shall meet the design requirements; when there are no specific requirements in the design, the following provisions shall be met: ① for the longitudinal stressed reinforcement, the area percentage of longitudinal tensile reinforcement lap joint shall meet the design requirements For beam, plate and wall components, it should not be more than 25%; for column components, it should not be more than 50%; when it is necessary to increase the joint area percentage in the project, it should not be more than 50% for beam components; for other components, it can be relaxed according to the actual situation

.

☀ Every day push the construction industry atlas specifications, examination information, program details, construction skills and many other high-quality content, to create their own wechat platform! It’s right to pay attention to us! I

.

For beams, columns and independent foundations, 10% and no less than 3 components shall be inspected; for walls and slabs, 10% and no less than 3 representative natural rooms shall be inspected; for large space structures, walls can be divided into inspection surfaces according to the height of about 5m between adjacent axes, and slabs can be divided into inspection surfaces according to the longitudinal and transverse axes, 10% and no less than 3 surfaces

.