If the steel bar is not correct, it can be sleeved and broken with steel pipe.

It is strictly prohibited to cut off by a shear or cut off by gas cutting.

(4) if the main reinforcement of the column is overlapped with plain round reinforcement, the corner hook shall be 45 ° with the formwork, and the hook of the middle reinforcement shall be 90 ° with the formwork.

Among them, if the stirrup is overlapped by 90 °, the overlapped part shall be welded, and the weld length of single-sided welding shall not be less than 10d.

There are four main reinforcement connection modes: binding and overlapping, mechanical connection, welding and casing grouting connection.

During spot welding of hot-rolled reinforcement, it shall be 25% ~ 45% of the diameter of smaller reinforcement; during spot welding of cold-rolled ribbed reinforcement, it shall be 25% ~ 40% of the diameter of smaller reinforcement.

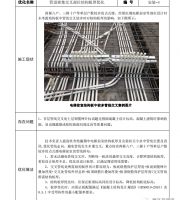

(3) When the foundation slab adopts double-layer reinforcement mesh, the reinforcement support foot or concrete support foot shall be set under the upper reinforcement mesh to ensure the correct position of the reinforcement.

(3) When welding the T-joint between reinforcement and embedded parts, submerged arc pressure welding, arc welding or perforated plug welding can also be used, but the welding current should not be large to prevent the reinforcement from being burned.

(3) After the quality inspection of the connecting sleeve screw thread is qualified, both ends shall be protected with plastic sealing covers, and the plastic protective cap shall be worn immediately after the reinforcement threading to ensure that the screw thread is not damaged.

At the same time, it is strictly prohibited to pour the flux from one side of the tank when pouring the flux into the tank.

Too large warehouse separation distance may cause the slurry in the sealed cabin to be not dense, so the warehouse separation distance should be 1.5 ~ 2m.

(4) After the mortar flows out of the sleeve grout discharge hole in a columnar shape, it shall be immediately blocked with a rubber plug.

Welding (1) Before reinforcement welding, rust spots, oil stains and sundries on the welding parts of reinforcement and steel plate and the surface of the contact between reinforcement and electrode shall be removed; if the end of reinforcement is bent and twisted, it shall be straightened or cut off.

Mechanical connection (1) the steel bar shall be cut off by a grinding wheel cutter, and the cutting surface shall be perpendicular to the steel bar axis without horseshoe shape and warpage.

Reinforcement engineering is an indispensable key project in building construction, and the most important thing in reinforcement engineering is reinforcement connection.

It can be extended after the solid grouting test is determined to be feasible, but it should not exceed 3M.

(2) during the processing of straight thread screw head, the steel bar shall be clamped in the centering clamp, and the axial clamping position of the steel bar shall be flush with the end face of the rolling head, and the error shall not be greater than 4mm.

(5) pneumatic welding can weld reinforcement in any direction, such as transverse and vertical, but during construction, it shall be noted that the diameter difference between welded reinforcement shall not be greater than 7mm.

Casing grouting connection (1) During construction, the steel bar position inspection template shall be used for detection, and the deviation of the steel bar position shall not be greater than ± 3mm.

(4) The pressing depth of resistance spot welding shall be selected according to different reinforcement.

At the same time, the position of the joint bar must be fixed firmly to avoid the deviation of the column axis.

If multiple joints are grouted at one time, the grouting or grout discharge holes that have discharged the cement mortar shall be blocked successively until the grout discharge holes of all joints are blocked…

(5) When the joint bar used for the connection between the cast-in-situ column and the foundation is connected, the stirrup shall be one diameter smaller than the column bar for connection.

The construction key points of each reinforcement connection mode are introduced below for reference.

(2) too small warehouse separation distance is easy to cause excessive pressure in the sealed cabin during grouting, and the seat slurry will be long cracked or extruded.

(3) When the electric grouting pump is used for grouting, the length of a single bin is generally not more than 1m.

(2) within the lap length, the binding buckle of the reinforcement shall not be less than 3, and the binding buckle shall be inward of the column to facilitate the upward movement of the stirrup.

(4) the semi-finished products of reinforcement connection shall be stacked neatly according to the specifications, marked and properly kept.

Binding and lapping (1) during binding and lapping, the number of stirrups in each column shall be calculated according to the spacing required in the drawing, and the stirrups shall be sleeved on the lap bars protruding from the lower layer, and then the column reinforcement shall be erected.

(2) When electroslag pressure welding is adopted, the upper and lower jaws of the welding machine shall be concentric, and the welding ends of the reinforcement shall be aligned, pressed and kept vertical.

(6) in areas with seismic requirements, the end of the column stirrup shall be bent into 135 °, and the straight length shall not be less than 10d (D is the diameter of the stirrup).