At this time, pay attention to the deviation of pile position.

(3) main tools: shovel, bucket, bucket, hose, watering pot, iron screen, hand push rubber cart and so on.

3.

The backfilling and re striking can be carried out several times.

Rammed fill and lime shall be sent to the laboratory for raw material test and compaction test in advance to obtain the maximum dry bulk density and optimal water content.

(3) ① construction sequence: bottom cleaning and tamping → lime soil mixing → virtual filling → tamping → pile forming.

The depth of foundation treatment is 5 ~ 15m.

Quicklime is used to make columns in the foundation.

The bearing capacity and compaction effect meet the design requirements.

3、 Construction method 1 Construction process 2 Construction method (1) the prepared soil is natural cohesive soil and silt with plasticity index greater than 4, free of organic impurities.

② The compaction shall be carried out in strict accordance with the parameters determined by the test, and the blanking speed and hammering times shall be matched to ensure the compaction coefficient.

The water content can be identified on the spot according to the standard of “holding in a ball, landing and flowering”, and the prepared lime soil materials shall not be used every other day.

③ Pile hole inspection: after the hole is formed, the pile hole shall be inspected and accepted in time.

Its particles shall not be greater than 5mm.

The chemical properties of this material are pneumatic and hydraulic, which gradually improves the strength of soil.

3.

It shall be digested and screened 1 ~ 2 days before use.

Lime soil compaction pile is suitable for treating collapsible loess, plain fill and miscellaneous fill above groundwater level.

③ After setting out, the construction can be carried out only after being confirmed by the on-site supervisor.

If it passes through stagnant sand layer or comes into contact with surface water, its effect will be significantly reduced.

In terms of mechanical properties, it can achieve the effect of compacting the foundation, improve the bearing capacity of the foundation, eliminate the collapsibility, make the settlement uniform and reduce the settlement.

4、 Quality control 1 Setting of quality control points for lime soil compaction pile 2 Pile position setting out ① strictly implement the specification requirements to ensure the setting out error of pile position.

② According to the site conditions, the setting out of pile position should be completed at one time, and the pile position protection and identification should be done well.

(2) Tamping equipment: winch, lifting tamping machine or eccentric clamping rod tamping machine and pear hammer.

(5) The hole forming, tamping process and compaction effect tests have been carried out to determine the relevant construction process parameters (layered filler thickness, tamping times, dry density after tamping and piling sequence), and the test pile has been tested.

② install the tamping machine, adjust and check the mechanical tamping.

Lime and soil materials shall be evenly mixed according to the specified mix proportion.

It shall not contain immature quicklime block particles and other impurities, nor contain too much water.

(6) Water supply, power supply, transportation roads and small temporary facilities on site have been set up.

reinforcement mechanism lime soil compaction pile method is the method of driving sand pile.

Quicklime is thoroughly digested into lime powder with water, screened with 5mm sieve and mixed with soil.

When the main purpose is to improve the bearing capacity of foundation soil or enhance water stability, lime soil compaction pile method should be selected.

Through the digestion and water absorption of quicklime, hydrate and capillary water absorption are generated to reduce the water content in cohesive soil, so as to improve the strength of foundation and reduce the settlement.

Requirements for materials, machines, equipment and operating conditions 1 Material requirements (1) soil material: clay excavated on site and silt with plasticity index greater than 4 can be used, without organic impurities or cultivated soil; The soil material shall be screened and its particle size shall not be greater than 15mm.

II.

After mixing, they shall be screened with a 15mm sieve, which can be used in the project.

Before filling, tamp the hole bottom for at least 5 times.

The inspection contents include: pile diameter, hole depth, verticality, shrinkage, hole collapse, back silting, etc.

Row by row from outside to inside to ensure the compaction effect between piles.

When the moisture content of the local foundation soil is greater than 24% and the saturation is greater than 65%, the lime soil compaction pile method should not be selected.

(4) The pile axis control pile and benchmark pile have been set, numbered and rechecked; The pile hole position has been set out, and the stake has been nailed for positioning or lime has been sprinkled.

③ The lime soil shall be evenly mixed with the same color, and the water content shall be strictly controlled..

The lime soil compaction pile is a pile formed by mixing lime and soil according to a certain volume ratio and tamping and densification in the hole.

Each 0.05m can be used for filling ³ Compaction 6 times.

The color is consistent and the water content is controlled at the optimal water content.

Requirements for operation conditions (1) geotechnical investigation report, foundation construction drawings and construction organization design shall be complete.

In case of hole collapse or diameter reduction, backfill lime soil shall be used for re excavation.

(2) After the hole forming is adjusted and the machinery is checked, the hole forming shall be started.

② After the drilling rig is in place, the center of the hammer shall be aligned with the ash point, and the hammer can be opened only after being approved by the technicians on duty.

In the process of hole forming, the falling distance of heavy hammer shall be adjusted in time according to the soft and hard conditions of the formation.

(3) The construction site has been leveled, the soft site where the pile driver operates has been preloaded, and effective drainage measures have been taken around.

(4) Tamping ① bottom cleaning and tamping: before lime soil tamping, the bottom of pile hole shall be cleaned and tamped, and the tamping times shall not be less than 6 times until the falling thickness in the hole is less than the specified value.

Source: Zhulong community I.

(2) All obstacles on the ground, underground pipelines, cables and old foundations of the construction site have been removed and relocated.

(2) Lime: fresh block ash above grade III shall be used.

The hole forming ① site must be flat and the elevation shall be less than the specified error.

Using it to improve the foundation can play a role in a short time.

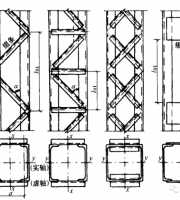

The hole forming construction sequence should be carried out according to the interval method, as shown in the figure.

Effective protective measures shall be taken when the immersed pipe vibration has an impact on adjacent buildings and instruments and equipment in the plant.

③ Fill in the hole forming records and tamping records, especially the records of hole forming hammering and tamping number, lime soil filling amount, etc.

If the repeated backfilling and re striking are invalid, other feasible methods can be discussed with the supervisor, the designer and Party A.

Main machines and equipment (1) hole forming equipment: 0.6T or 1.2t diesel pile driver or self-made hammer pile driver, impact drill or Luoyang shovel can also be used.

2.