Binding pad stone reinforcement.

After the initial setting of the concrete, the steel pipe shall be carefully rotated and pulled out.

Control points: the steel pipe cannot be pulled out too early, which will cause shrinkage; The steel pipe shall not be pulled out too late.

The manufactured locking device shall be removed from the rubber support near the stop, because it cannot be removed later.

Make several sets of formwork according to the floor size of each rubber bearing, draw two center lines of the formwork on the formwork, and extend the connecting line of the anchor bolt center to the formwork end.

2.

2、 The maximum thickness of pad stone calculated by each data is: 25-9 = 16cm; Minimum thickness of pad stone: 25-10.5 = 14.5cm; Maximum depth of ground bolt penetrating into main reinforcement of bent cap: 25-14.5-6 = 4.5cm; (here 25 is the bolt length and 6 is the thickness of the protective layer).

After the reinforcement of bent cap is bound, the side formwork installation is completed.

Therefore, starting from the construction of bent cap, we should consider the position of anchor bolts.

Grout the reserved holes so that the grouting material is closely bonded with the anchor bolts and pad stone concrete.

It is suitable for long-span bridges.

The minimum depth of the ground bolt into the main reinforcement of the bent cap: 25-16-6 = 3cm; (here 25 is the bolt length and 6 is the thickness of the protective layer).

The length of anchor bolts is 25cm, the diameter of nut is 4cm and the diameter of screw is 2cm.

Cushion stone construction is easy to take detours.

The concrete shall be poured after passing the inspection.

The flatness of the top surface of the pad stone is easy to exceed the specification requirements, and can only be leveled by epoxy resin.

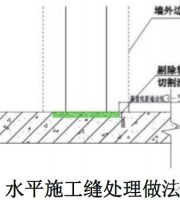

4、 During pad stone construction and pouring of pad stone concrete, insert the steel pipe into the hole, install the formwork, mark the corresponding elevation on the top of the formwork, calculate the top elevation of the pad stone, and snap a fine ink line on the inner side of the formwork to control the top elevation of the pad stone with an accuracy of 2mm.

Therefore, basin rubber bearings have been widely used in the fields of urban bridges, highway bridges and railway bridges.

We should determine the most appropriate steel pipe removal time according to the concrete grade, that is, the temperature of the day.

The pad stone concrete shall be poured after passing the inspection.

At this point, it is not difficult to see that the anchor bolts will conflict with the main reinforcement of our bent cap frame.

One end of the short steel pipe shall be welded with the inner diameter contact surface of the steel pipe with a round steel plate with a diameter of 7.6cm to prevent concrete from entering the steel pipe; The other end is made of 30cm long Φ 20.

1、 Project overview a large bridge project adopts post tensioned prestressed T-beams.

Draw the support sideline and beam falling sideline on the pad stone with a corner ruler and colored pen.

After leveling, set out the center of the pad stone, mark it, connect the center line of the pad stone, and pop up the ink line.

4.

2.

The manufacturing quantity shall meet the requirements of on-site sequential construction.

the end points of each control line on the formwork).

The galvanized steel pipe with an inner diameter of 8cm shall be processed into a short steel pipe with a length of 30cm.

The removal process must be slow and do not cause great disturbance to the concrete around the pipe.

3、 After many years of practice in bent cap construction, our construction experience is that sufficient preparations should be made before bent cap construction, mainly including the following points: 1.

As a bridge builder, we should do these key but small details for the century old bridge.

The waste of short reinforcement shall be welded with the top surface of the steel pipe, and 10cm shall be reserved at both ends of the steel pipe to facilitate the pulling out of the steel pipe during the initial setting of concrete.

The grouting of the reserved hole of the anchor bolt of the rubber bearing is not dense, and the grouting material cannot be dense..

3.

Dig out 10cm circular hole at the anchor bolt position, and the center of the circular hole must coincide with the center of the anchor bolt of the rubber bearing, with an error of 2mm.

Place the fabricated corresponding formwork on the bent cap reinforcement, set out the center of the bearing pad stone with a qualified total station, and adjust the main reinforcement and stirrup affected by the reserved hole.

Draw a line on the reinforcement around the formwork with a stone pen and mark the corresponding control points (i.e.

The steel pipe must be vertical.

The rubber bearing and pad stone are not closely pasted.

The center of pad stone shall be compounded again to ensure that the main reinforcement, stirrup and reserved hole have no influence.

In recent years, with the rapid development of bridges, bearing pad stone, as the most key part of bridges, has gradually attracted people’s attention.

3.

Take a project as an example, let’s take a look first.

The rubber bearing is temporarily connected, placed and fabricated, and the position is adjusted according to the ink line.

The mobility of construction personnel is large, experienced personnel are promoted, and the on-site management personnel are mostly newly graduated students, or their experience is limited, and there is less technical guidance on the site.

The spacing of pad stone reinforcement is 10cm, and the design strength of pad stone is C40.

As we all know, basin rubber bearing has the characteristics of large bearing capacity, large horizontal displacement and flexible rotation, and has the advantages of light weight, compact structure, simple structure, low building height, convenient processing and manufacturing, steel saving and cost reduction.

5、 Installation of rubber bearing before the installation of rubber bearing ruler and pointer, the elevation of pad stone must be re measured, and the pad stone shall be leveled with epoxy resin according to the re measured data.

6、 After the completion of the system transformation, the construction quality of the bearing pad stone directly affects the service life of the rubber bearing, and the rubber bearing directly affects the operation state of the whole bridge.

If the concrete is strengthened too late, it will not be pulled out.

Problems in the construction of bearing pad stone and basin rubber bearing 1.

After the initial setting of the poured concrete, the steel pipe shall be taken out slowly and the bent cap shall be cured.

Remove the formwork, restore the reserved hole position according to the control sideline, that is, the control point, install the fabricated steel pipe, and spot weld the steel pipe on the bent cap frame with short reinforcement.

The whole bridge has 18 spans, each span is 30m long, 10 T-beams, the spacing of main reinforcement of bent cap is 10cm, the thickness of top protective layer is 6cm, the thickness of pad stone is 25cm – the height of rubber bearing (after design change), and the thickness of GPZ (Ⅱ) 1.5sx and DX are 9cm; The thickness of GPZ (Ⅱ) 2.5sx and DX is 10.5cm; GPZ (Ⅱ) 2.5gd is 10cm thick.